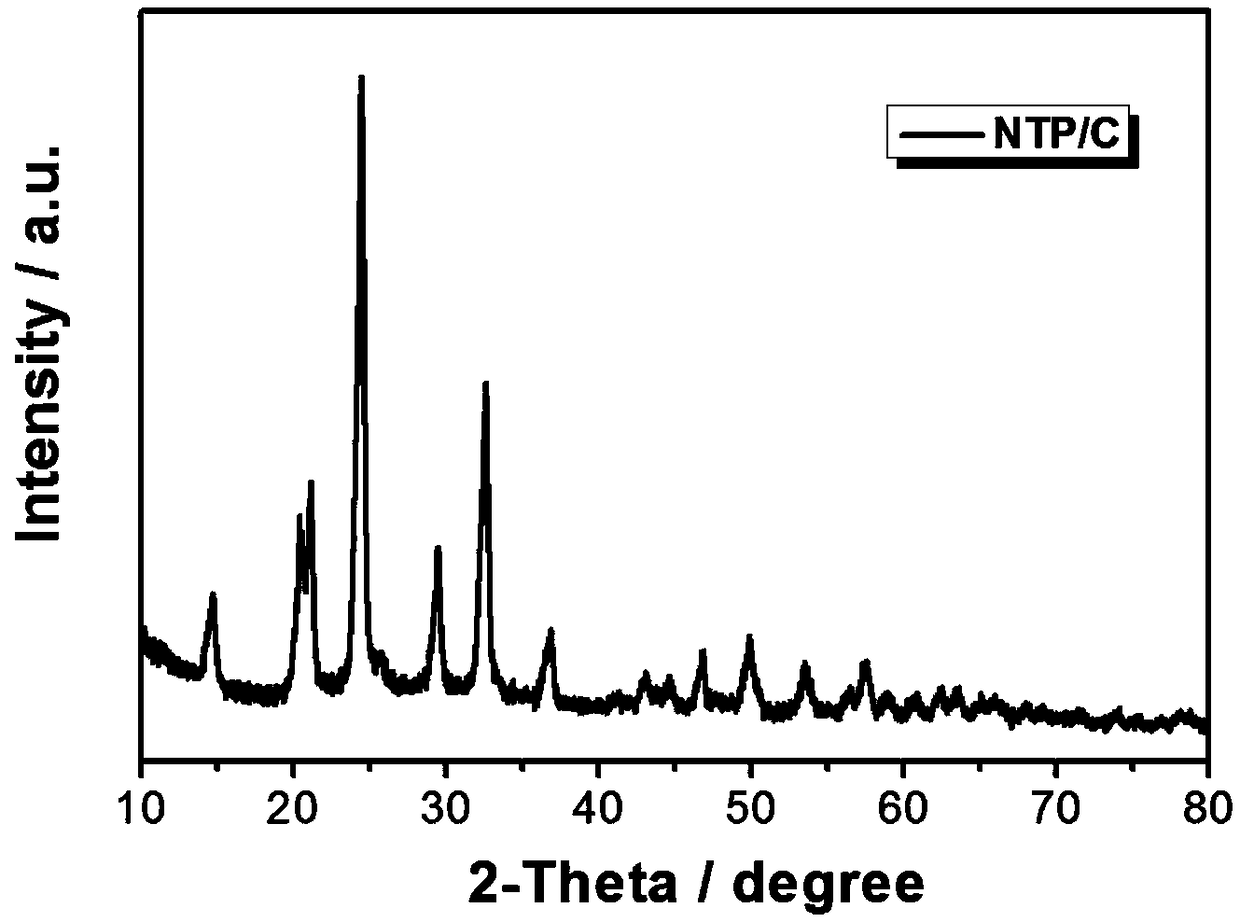

Preparation method and application of sodium titanium phosphate/carbon composition material

A technology of carbon composite materials and sodium titanium phosphate, applied in the field of materials, can solve the problems of full release of electrochemical performance, general electrochemical performance, uneven fiber morphology, etc., achieve high fiber fineness and uniformity, and improve ion migration The effect of improving the rate and electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of a kind of sodium titanium phosphate / carbon composite material described in this embodiment is prepared according to the following steps:

[0040] (1) Preparation of sodium titanium phosphate precursor solution: Take 10ml of absolute ethanol and add it to a beaker at room temperature, then heat it to 65°C and keep it at a constant temperature, weigh 0.68g of phosphorus pentoxide (P 2 o 5 ) into ethanol, continue to maintain a constant temperature of 65 ° C, and stir evenly to obtain a colorless solution 1; then weigh 2.14 g of isopropyl titanate with a mass concentration of 98%, add it to the above colorless solution 1, and continue to maintain 65 ° C Constant temperature, stir to obtain solution 2; Finally, weigh 0.53g of sodium acetate (CH 3 COONa) was added to solution 2, and continued to maintain a constant temperature of 65° C., and stirred evenly to obtain a sodium titanium phosphate precursor solution;

[0041] (2) Take 0.7g of polyviny...

Embodiment 2

[0051] The preparation method of a kind of sodium titanium phosphate / carbon composite material described in this embodiment is prepared according to the following steps:

[0052] (1) Preparation of sodium titanium phosphate precursor solution: Take 10ml of absolute ethanol and add it to the beaker at room temperature, then heat it to 20°C and keep it at a constant temperature, weigh 0.588g of phosphoric acid and add it to the ethanol, continue heating to 60°C at a constant temperature, Stir evenly to obtain a colorless solution 1; then weigh 0.681 g of tetrabutyl titanate with a mass concentration of 98%, add it to the above-mentioned colorless solution 1, continue to maintain a constant temperature of 60°C, and stir evenly to obtain a solution 2; finally weigh 0.106 Add 2 g of sodium carbonate to solution 2, continue to maintain a constant temperature of 60 ° C, and stir evenly to obtain a sodium titanium phosphate precursor solution;

[0053] (2) Take 0.25g polyvinylpyrrolid...

Embodiment 3

[0060] The preparation method of a kind of sodium titanium phosphate / carbon composite material described in this embodiment is prepared according to the following steps:

[0061] (1) Preparation of sodium titanium phosphate precursor solution: Take 10ml of absolute ethanol and add it to the beaker at room temperature, then heat it to 20°C and keep the temperature constant, weigh 0.691 ammonium dihydrogen phosphate and add it to the ethanol, heat it to 65°C Maintain a constant temperature and stir evenly to obtain a colorless solution 1; then weigh 0.1598g of titanium dioxide, add it to the above colorless solution 1, continue to maintain a constant temperature of 65°C, and stir evenly to obtain a solution 2; finally weigh 0.168g of sodium bicarbonate and add it to In solution 2, continue to maintain a constant temperature of 65°C and stir evenly to obtain a sodium titanium phosphate precursor solution;

[0062] (2) Take 1.0 g of polyvinylpyrrolidone (PVP), add it to the sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com