Processing method for building waste foamed concrete composite heat preservation building blocks

A technology of foamed concrete and construction waste, which is applied in the field of manufacturing building materials. It can solve the problems that the recycled aggregate cannot meet the foaming process, the aggregate body has not been effectively strengthened, and the overall uniformity of the recycled aggregate is not enough, so as to achieve the realization of resource utilization. efficient utilization, reduced water absorption, and the effect of saving natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

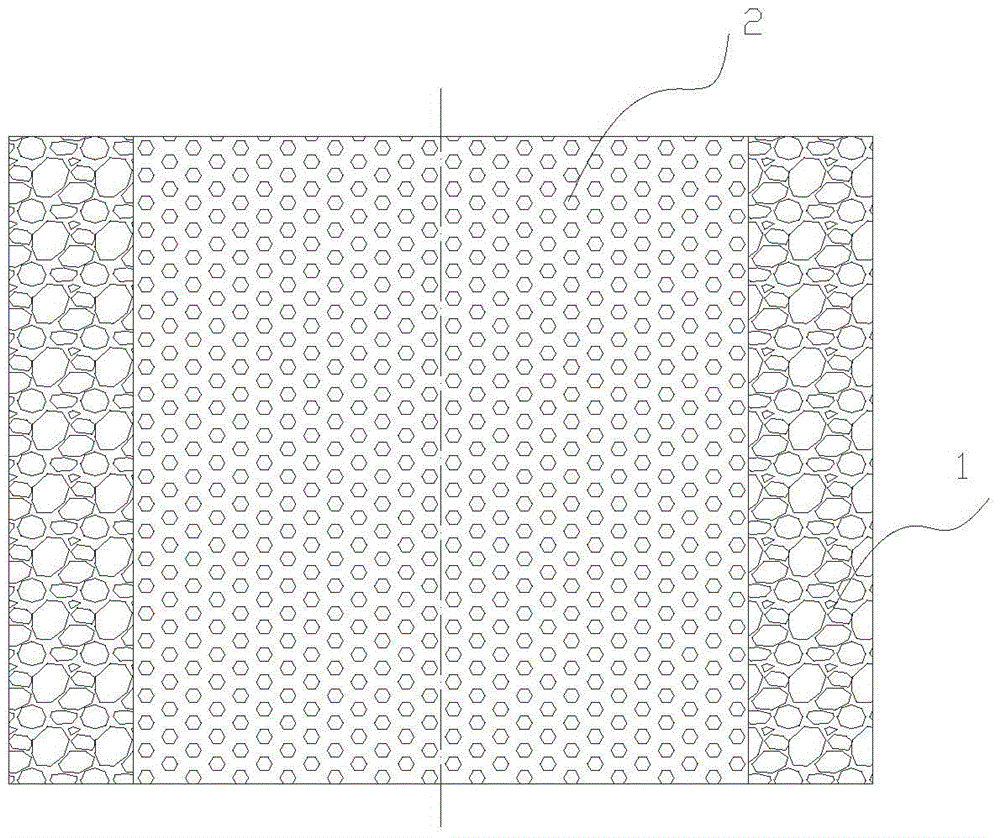

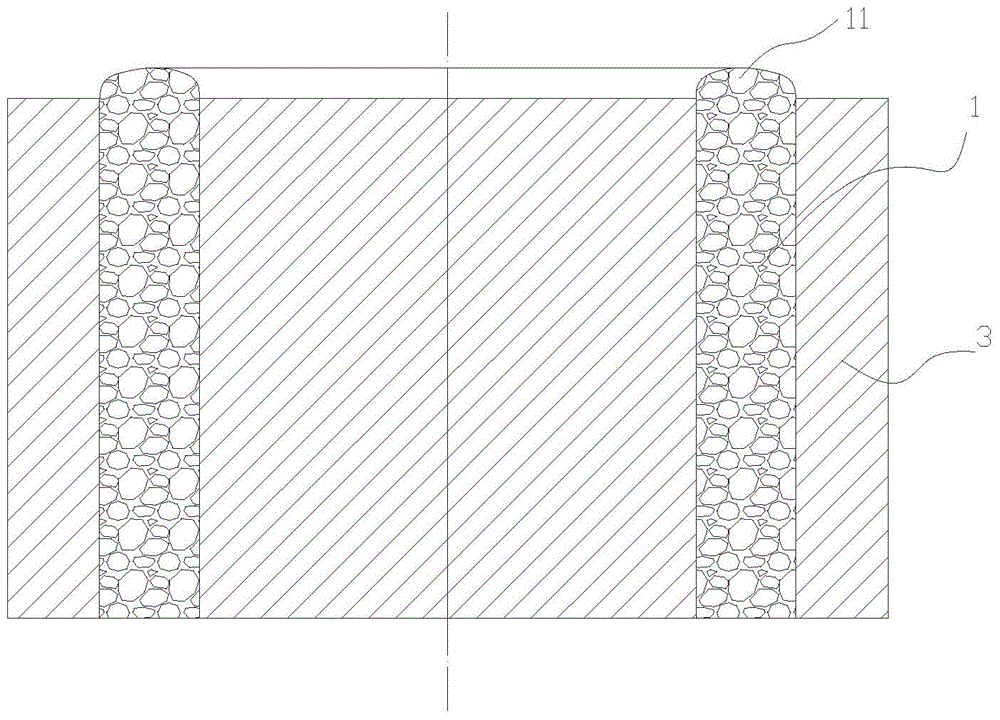

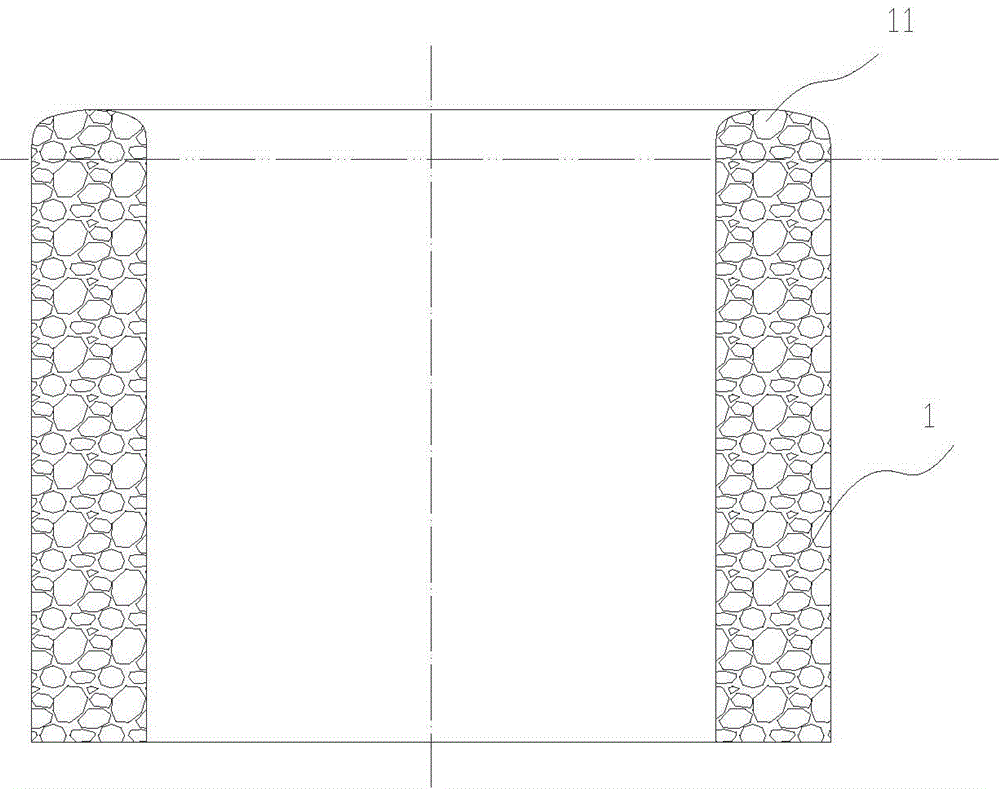

[0048] The invention is like Figure 1-8 As shown, the block includes a base 1 with a hollow cavity and an insulation core filled in the hollow cavity 1 (such as figure 1 ) 2. The block preparation process includes matrix forming, core preparation, curing and drying steps, and the matrix contains cement, active mixed materials, modifiers and recycled aggregate prepared from construction waste as raw materials;

[0049] The processing method of the recycled aggregate is:

[0050] 1) Classification and preliminary sorting of construction waste, and retain waste concrete construction waste and brick-concrete construction waste for later use;

[0051] 2) Rough crushing of construction waste, using a jaw crusher to coarsely crush the waste concrete construction waste and brick-concrete construction waste to obtain granular recycled coarse aggregate with a size of less than 10mm;

[0052] 3). Recycled coarse aggregate is mechanically strengthened. Natural sand 5 is added to recycled coarse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com