Modified Al2O3 carrier and preparation method thereof

A carrier and modification technology, used in catalyst carriers, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of catalyst activity and stability decline, easy loss, complex catalyst preparation methods, etc., to improve activity and selectivity properties, reducing surface acidity, high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

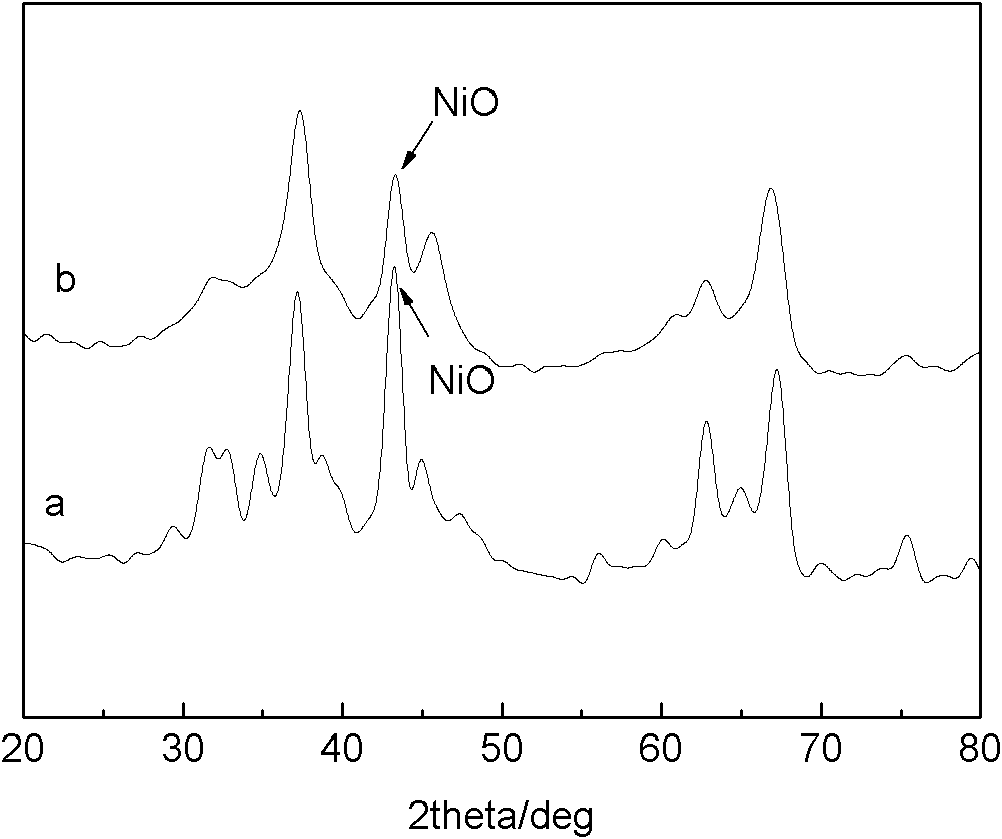

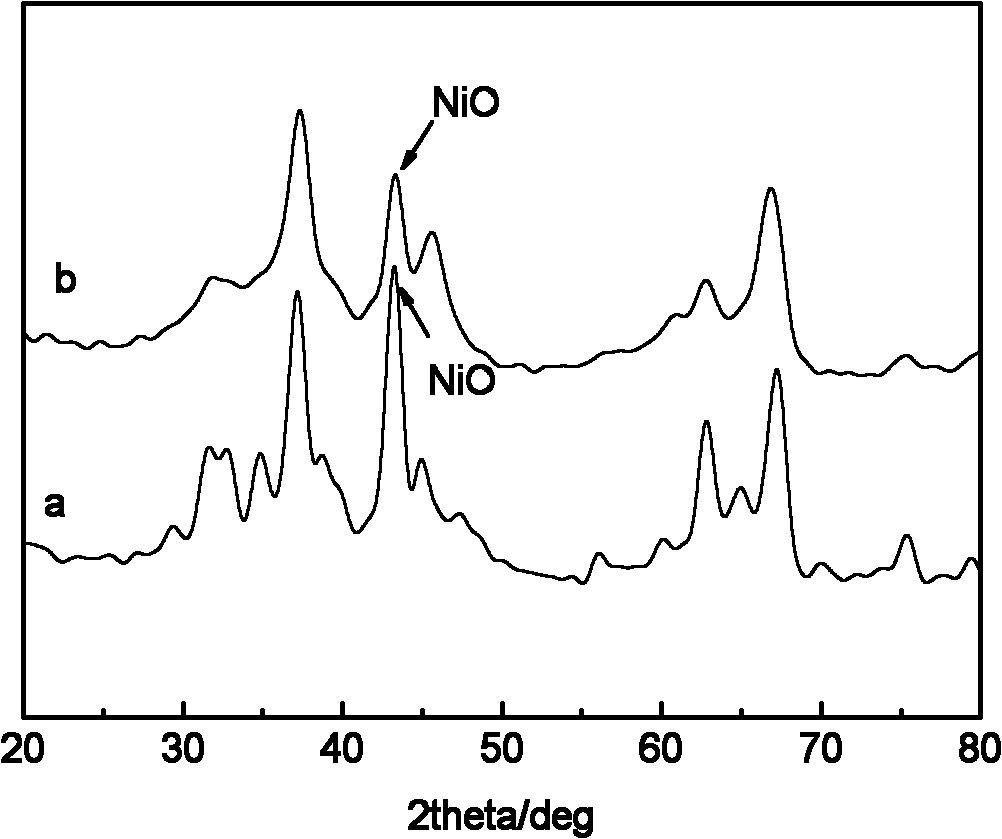

Image

Examples

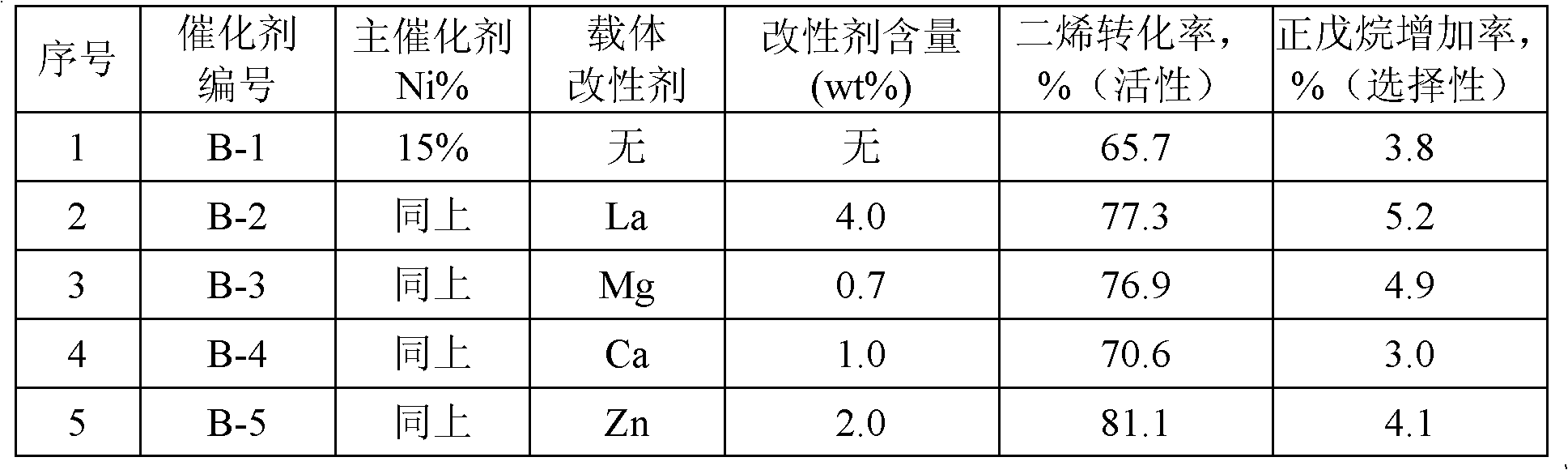

Embodiment 1

[0033] Take by weighing the carrier A-1 in 10g comparative example 1, use 1.25g lanthanum nitrate La (NO 3 ) 3 ·6H 2 The solution made of O and 6-7g distilled water is impregnated with equal volume for 3 hours, dried at 110°C for 2 hours in a blast drying oven, then vacuum-dried at 150°C for 2 hours, and finally in a muffle furnace. Calcined at 1000°C for 2 hours in an air atmosphere to prepare a carrier La with a lanthanum content of 4wt%. 2 o 3 -Al 2 o 3 , the La that enters into the spinel compound accounts for 85wt%, which is recorded as carrier A-3. The structural formula of the spinel compound formed on the surface of the carrier is LaAlO 3 .

Embodiment 2

[0035] Take by weighing the carrier A-3 prepared in 10g embodiment 1, use 7.42g nickel nitrate Ni (NO 3 ) 2 ·6H 2 A solution made of O and 3-4g distilled water was impregnated in equal volume for 3 hours, dried at a constant temperature at 110°C for 2 hours in a blast drying oven, then dried at a constant temperature and vacuum at 150°C for 2 hours, and finally in a muffle furnace. The lanthanum-modified catalyst B-2 with a nickel loading of 15 wt% can be prepared by calcining at 300° C. for 2 hours in an air atmosphere.

Embodiment 3

[0037] Take by weighing the carrier A-1 in 10g comparative example 1, use 0.72g magnesium nitrate Mg (NO 3 ) 2 ·6H 2 The solution that O and 6-7g distilled water is made into carries out equal volume impregnation for 3 hours, carries out drying according to the drying condition among the embodiment 1, carries out 900 ℃ roasting of 4 hours under air atmosphere in the muffle furnace at last, prepares magnesium content 0.7wt% carrier MgO-Al 2 o 3 , the Mg entering into the spinel compound accounts for 92wt%, which is recorded as carrier A-4. The structural formula of the spinel compound formed on the surface of the carrier is MgAl 2 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com