Catalyst for hydrogenation refining of Fischer-Tropsch synthetic oil, as well as preparation method and application thereof

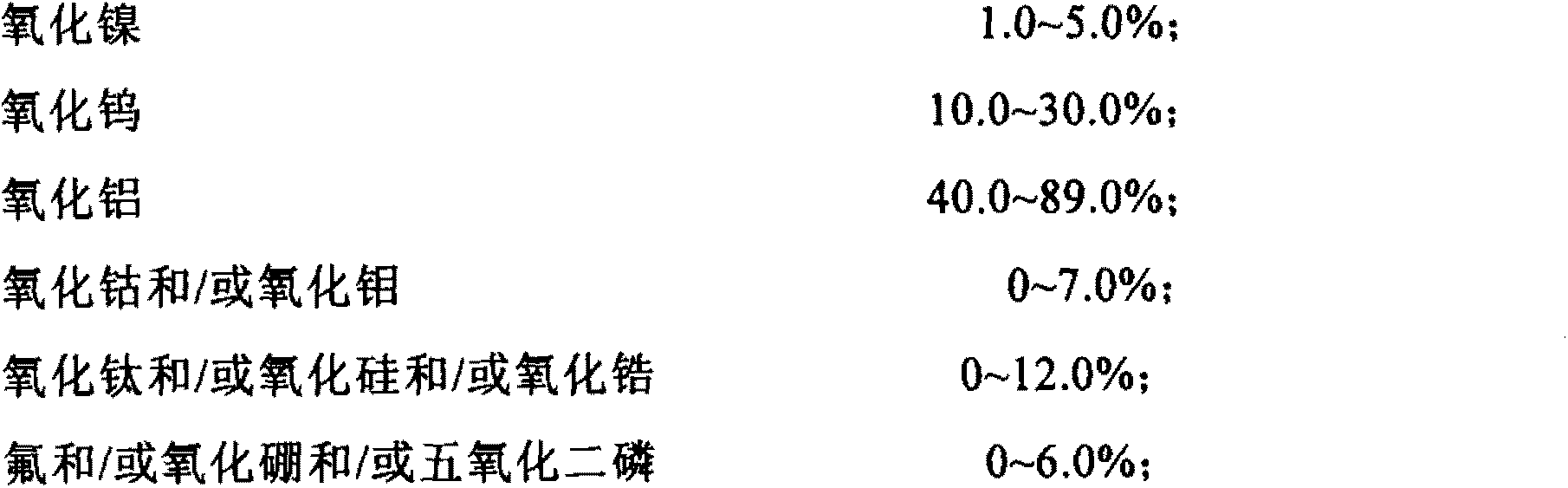

A Fischer-Tropsch synthetic oil and hydrofining technology, which can solve problems such as unsatisfactory hydrogenation activity through selective hydrofinishing, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. , to improve thermal stability, high olefin catalytic hydrogenation and oxygenate hydrogenation removal activity, improve acidity and surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

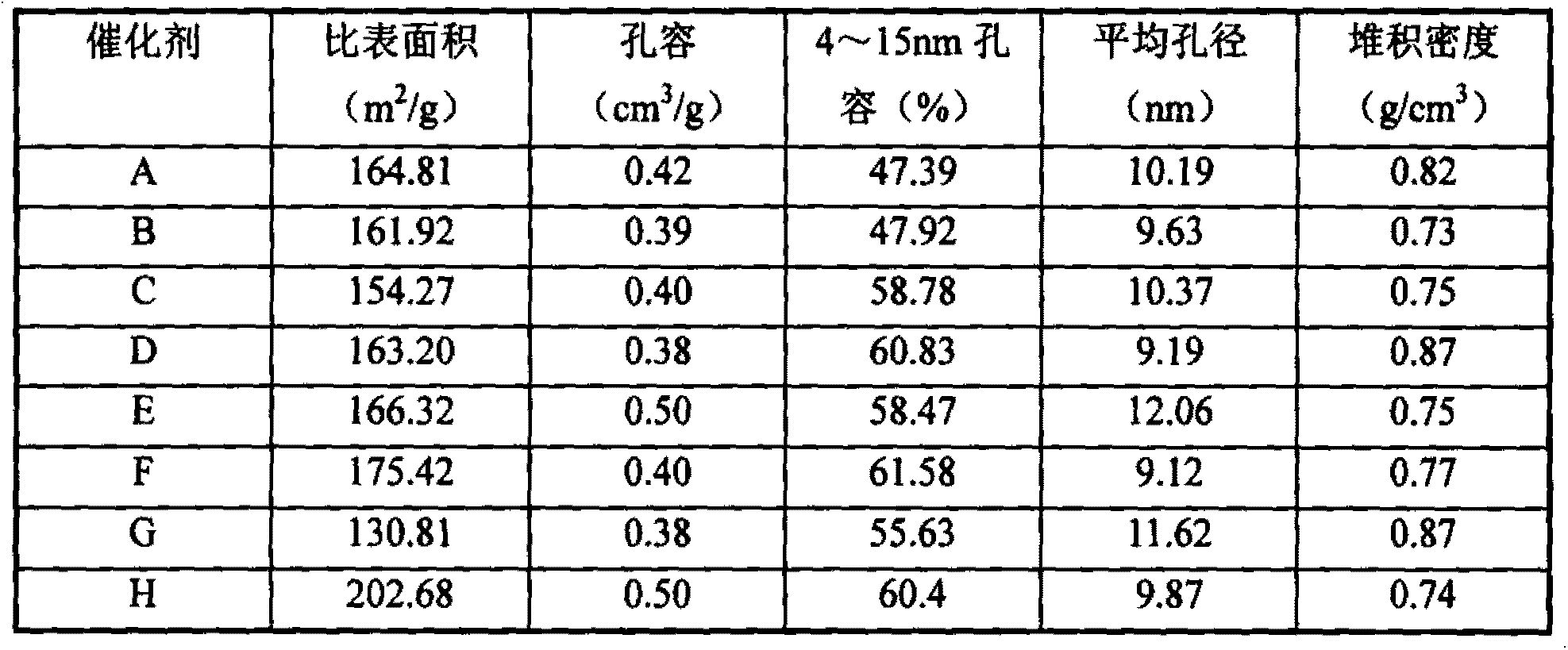

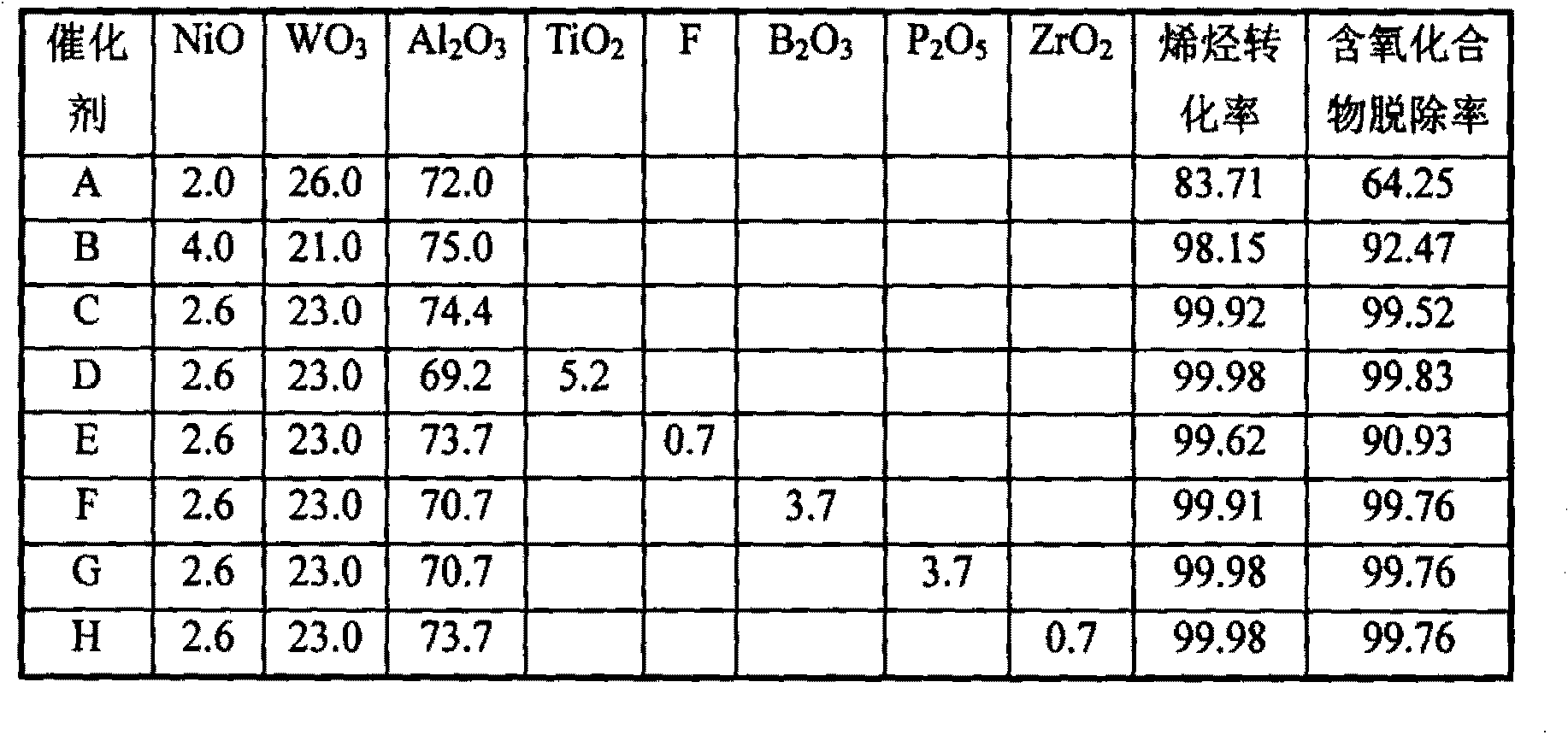

[0038] Weigh 100g of powdery pseudo-boehmite, add 100mL of deionized water according to the water-powder ratio of 1:1, stir well, and knead for 20min. After the kneading is completed, a 3mm cylindrical extrusion head is used to extrude on the extruder. The extruded carrier was dried at 60°C for 2h and at 120°C for 4h. Then the dried carrier was put into a muffle furnace and calcined at 550° C. for 4 h. After calcining, grinding and sieving are carried out to obtain the carrier A of 20-40 mesh.

[0039]Weigh 10g of carrier A, and prepare a mixed aqueous solution with a certain concentration of 1.0979g of nickel nitrate and 4.2484g of ammonium metatungstate according to the equal-volume impregnation method, and slowly add it dropwise to carrier A, stir evenly, and immerse for 24 hours. The impregnated catalyst was dried at 60°C for 2h and at 120°C for 4h. Then the dried catalyst was put into a muffle furnace and calcined at 500°C for 4h. After calcining, sieving was carried ...

Embodiment 2

[0042] Weigh 95g of powdery pseudo-boehmite, add 5g of scallop powder, stir well, then add 100mL of deionized water according to the water-powder ratio of 1:1, stir well, and knead for 20min. After the kneading is completed, a 3mm clover-shaped extrusion head is used to extrude on the extruder. The extruded carrier was dried at 60°C for 2h and at 120°C for 4h. Then the dried carrier was put into a muffle furnace and calcined at 550° C. for 4 h. After calcining, grinding and sieving are carried out to obtain the carrier B of 20-40 mesh.

[0043] Weigh 10g of carrier B, and prepare a mixed aqueous solution with a certain concentration of 2.1079g of nickel nitrate and 3.2941g of ammonium metatungstate according to the equal-volume impregnation method, slowly add it dropwise to carrier B, stir evenly, and immerse for 24 hours. The impregnated catalyst was dried at 60°C for 2h and at 120°C for 4h. Then the dried catalyst was put into a muffle furnace and calcined at 500°C for 4h...

Embodiment 3

[0046] Weigh 95g of powdered pseudo-boehmite, add 5g of scallop powder, stir well, add 100mL of 2wt% nitric acid solution, stir well, and knead for 20min. After the kneading is completed, a 3mm cylindrical extrusion head is used to extrude on the extruder. The extruded carrier was dried at 60°C for 2h and at 120°C for 4h. Then the dried carrier was put into a muffle furnace and calcined at 550° C. for 4 h. After roasting, grind and sieve to obtain the carrier C of 20-40 mesh.

[0047] Weigh 10g of carrier C, and prepare a mixed aqueous solution with a certain concentration of 1.3812g of nickel nitrate and 3.6369g of ammonium metatungstate according to the equal-volume impregnation method, slowly add it dropwise to carrier C, stir evenly, and immerse for 36h. The impregnated catalyst was dried at 60°C for 2h and at 120°C for 4h. Then the dried catalyst was put into a muffle furnace and calcined at 500°C for 4h. After calcination, sieve was carried out to obtain catalyst C o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com