Power battery and lithium ion electrolyte thereof

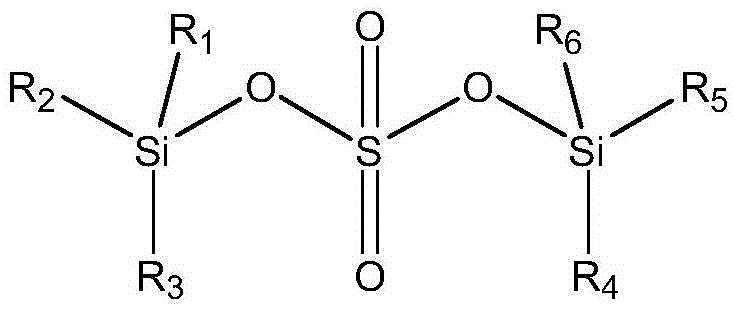

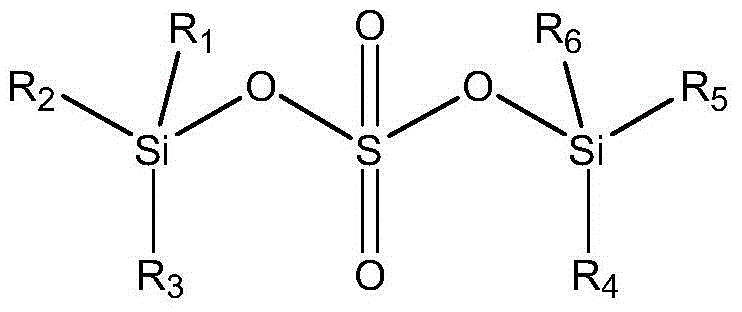

A lithium ion and electrolyte technology, applied in the field of lithium ion electrolyte and its power battery, can solve the problems of unreported high temperature performance, inability to play a protective role, low SEI film resistance, etc., to improve high temperature performance and cycle performance, The effect of improving cycle and high temperature performance, improving low temperature discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

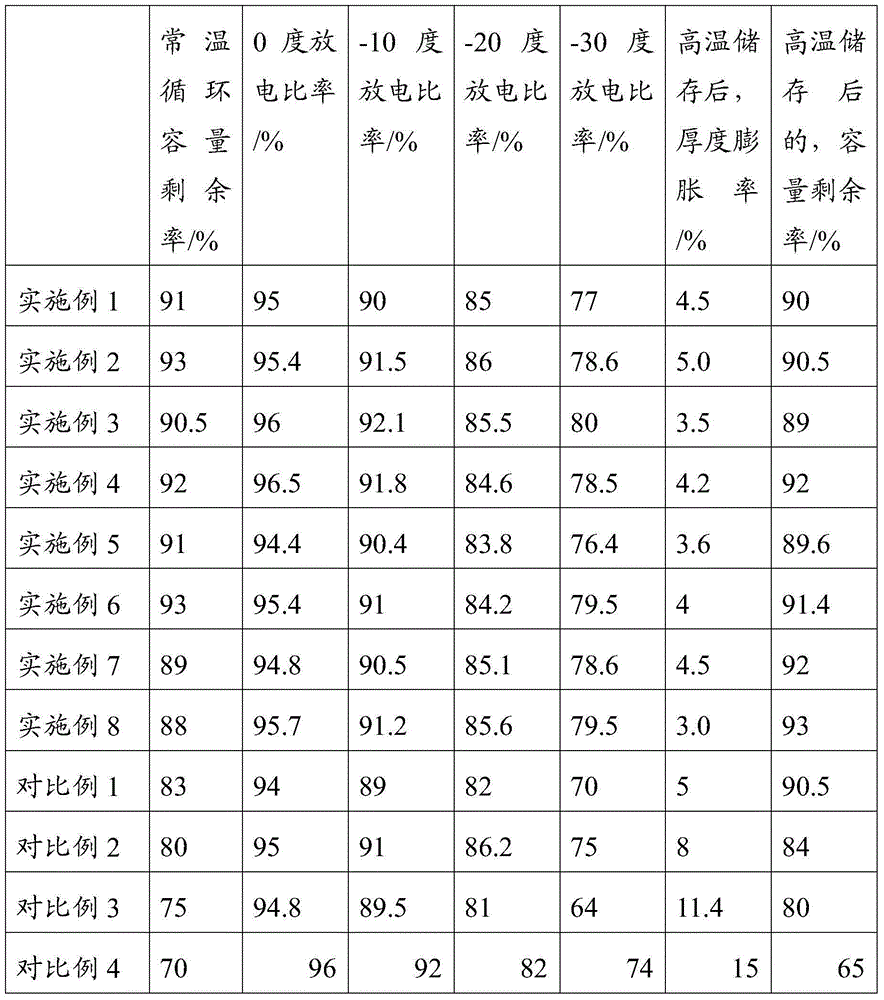

Examples

Embodiment 1

[0019] 1. Preparation of positive pole piece:

[0020] Lithium iron phosphate is used as the positive electrode active material, PVDF (polyvinylidene fluoride) is used as the binder, and conductive graphite is used as the conductive agent. After the mixed slurry is coated on both sides of the positive electrode current collector composed of aluminum foil, it is dried and pressed as Positive pole piece.

[0021] 2. Preparation of negative pole piece:

[0022] Using artificial graphite as negative electrode active material, SBR (polystyrene, butadiene suspension) as binder, CMC (sodium carboxymethyl cellulose) as thickener, conductive carbon black as conductive agent, the prepared slurry After the material is coated on both sides of the negative electrode current collector composed of copper foil, it is dried and pressed as the negative electrode sheet.

[0023] 3. Preparation of isolation membrane:

[0024] The isolation film is made of PP / PE / PP three-layer material.

[002...

Embodiment 2

[0030] The difference with embodiment 1 is:

[0031] In the mixed solvent, add 1.0wt% bis(trimethylsilane) silyl sulfate, 2wt% VC, 1wt% LiBF 4 . Other than that, everything else remains the same, and the process of making the battery is the same, so I won’t go into details here.

Embodiment 3

[0033] The difference from Example 1 is: 1.0wt% of bis(triphenylsilane) silyl sulfate, 2wt% of VEC, and 2wt% of LiDFOB were added to the mixed solvent. Other than that, everything else remains the same, and the process of making the battery is the same, so I won’t go into details here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com