Lithium-ion secondary battery and electrolyte thereof

A secondary battery and electrolyte technology, applied to secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of poor low-temperature charge and discharge characteristics of batteries, and the inability to fully meet the conductivity requirements of lithium-ion secondary batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

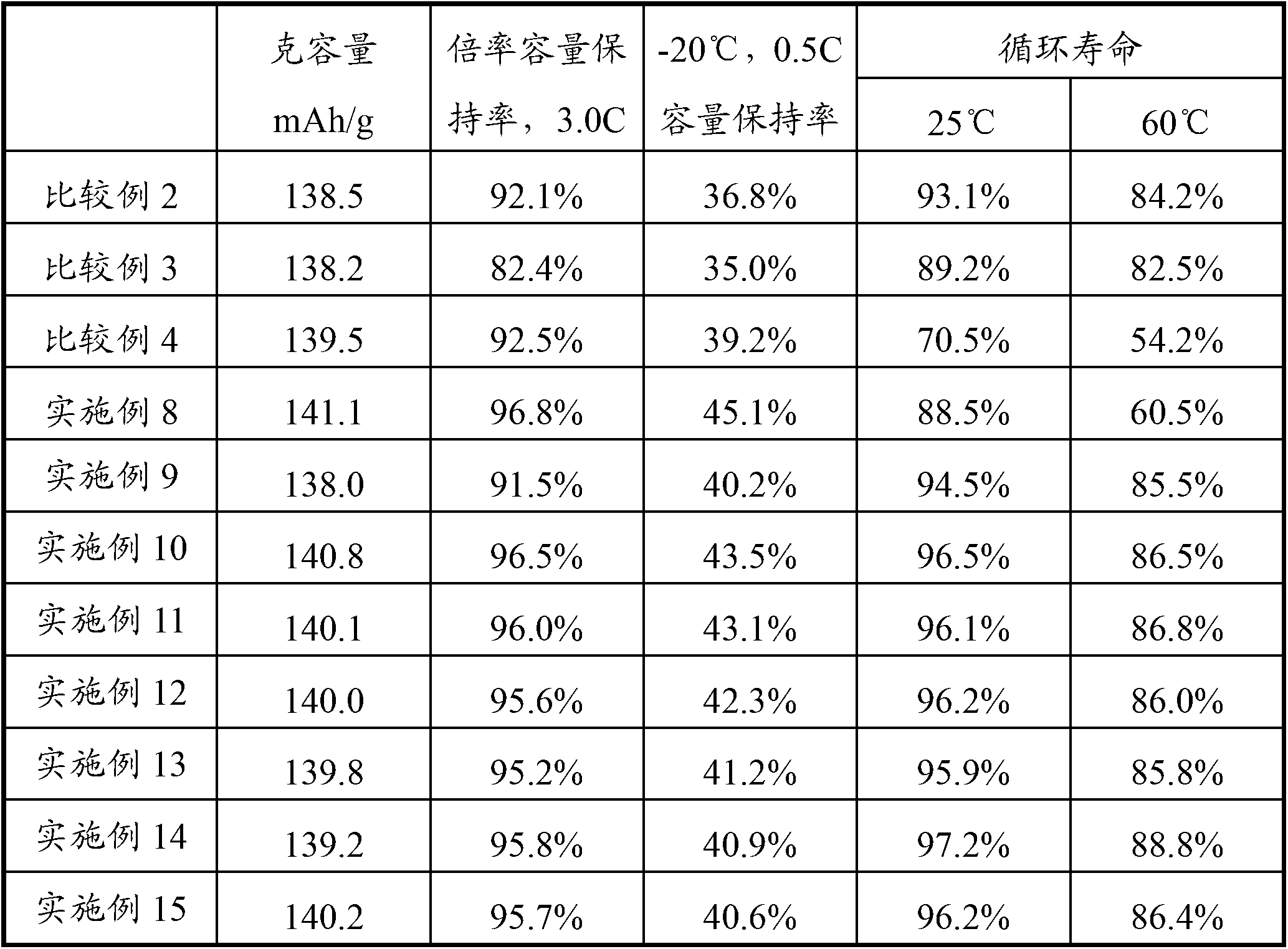

Examples

Embodiment 1

[0026] Example 1: Mix ethylene carbonate (EC), dimethyl carbonate (DMC), propylene carbonate (PC), and ethyl acetate (EA) in a mass ratio of 30:20:10:40, and add LiPF 6 , so that the concentration is 1.0mol / L, adding vinylene carbonate (VC) accounting for 2% of the total weight of the electrolyte.

Embodiment 2

[0027] Example 2: Mix ethylene carbonate (EC), dimethyl carbonate (DMC), propylene carbonate (PC), and ethyl acetate (EA) in a mass ratio of 30:20:10:40, and add LiPF 6 , so that the concentration is 1.0mol / L, add 2% of vinylene carbonate (VC) and 10% of fluoroethylene carbonate (FEC) accounting for the total weight of the electrolyte.

Embodiment 3

[0028] Example 3: Mix ethylene carbonate (EC), dimethyl carbonate (DMC), propylene carbonate (PC), and ethyl acetate (EA) in a mass ratio of 30:20:10:40, and add LiPF 6 , so that the concentration is 1.0mol / L, add 2% of vinylene carbonate (VC) and 4% of fluoroethylene carbonate (FEC) accounting for the total weight of the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com