High-voltage rate electrolyte with high-and-low temperature performance and lithium ion battery using electrolyte

A technology of electrolyte and lithium salt, which is applied in the field of lithium-ion battery preparation and high-voltage rate electrolyte, can solve the problems of aggravating the catalytic decomposition of electrolyte, greatly affecting the migration ability, and reducing the retention rate of capacity, so as to improve high-temperature storage Performance, wide liquid range, and the effect of reducing gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Electrolyte preparation steps: In a glove box filled with argon, ethylene carbonate, propylene carbonate, diethyl carbonate, and n-propyl propionate (that is, propyl propionate) are prepared according to the mass ratio of EC:PC:DEC :PP=20:20:45:15 for mixing, then slowly add lithium hexafluorophosphate to the mixed solution so that the concentration of lithium hexafluorophosphate in the electrolyte is 1.25mol / L, and finally add 1,2-bis( 2-cyanoethoxy)ethane (DENE), 0.5wt% vinyl sulfate (DTD), 0.3wt% vinylene carbonate (VC), 4wt% fluoroethylene carbonate (FEC), 3wt% propanesulfonic acid Lactone (PS), 0.5wt% lithium bisfluorosulfonyl imide (LIFSI), 0.3wt% lithium difluorophosphate (LIPO 2 f 2 ), 0.2wt% citraconic anhydride and stir evenly, obtain the lithium-ion battery electrolyte of embodiment 1.

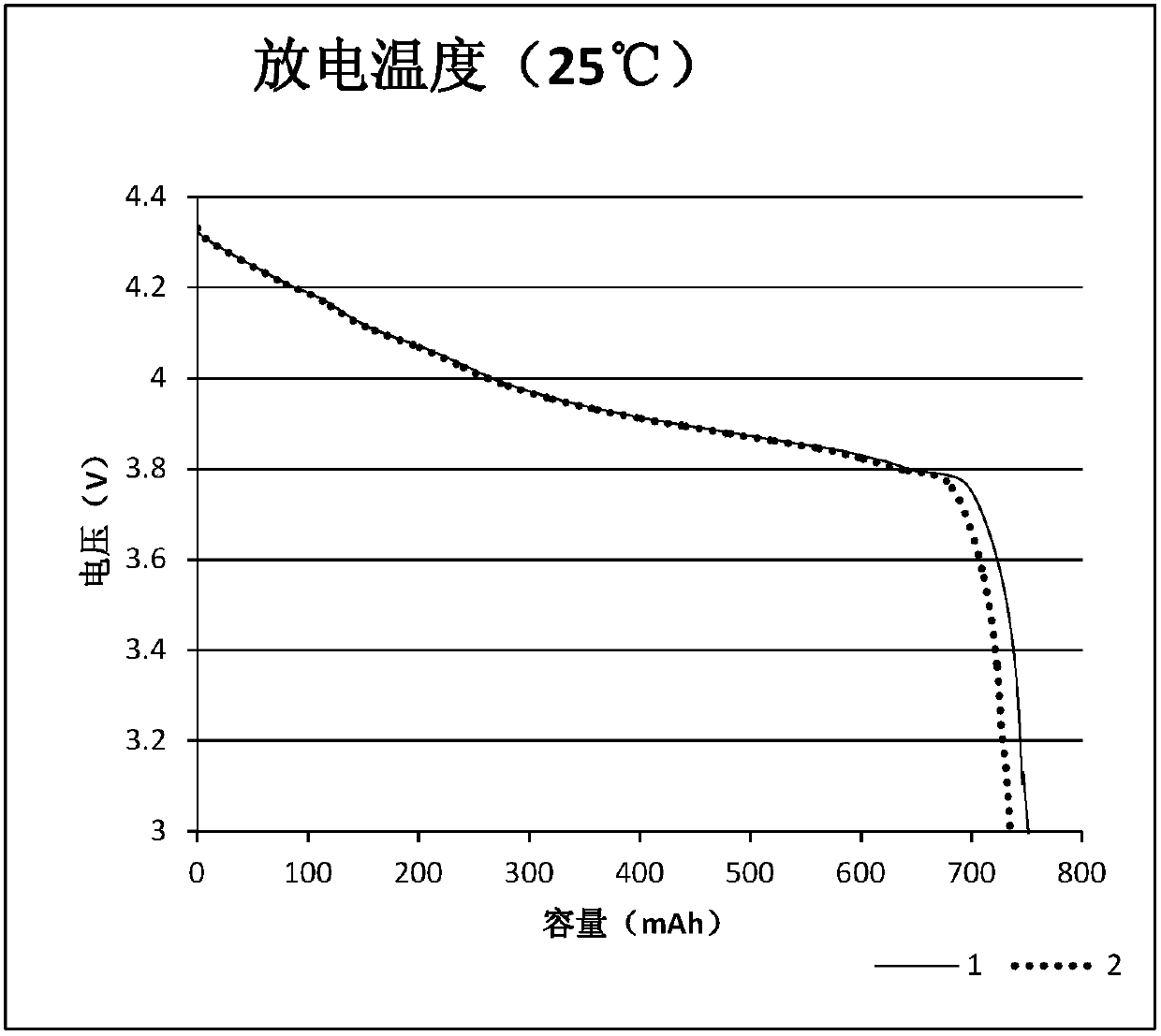

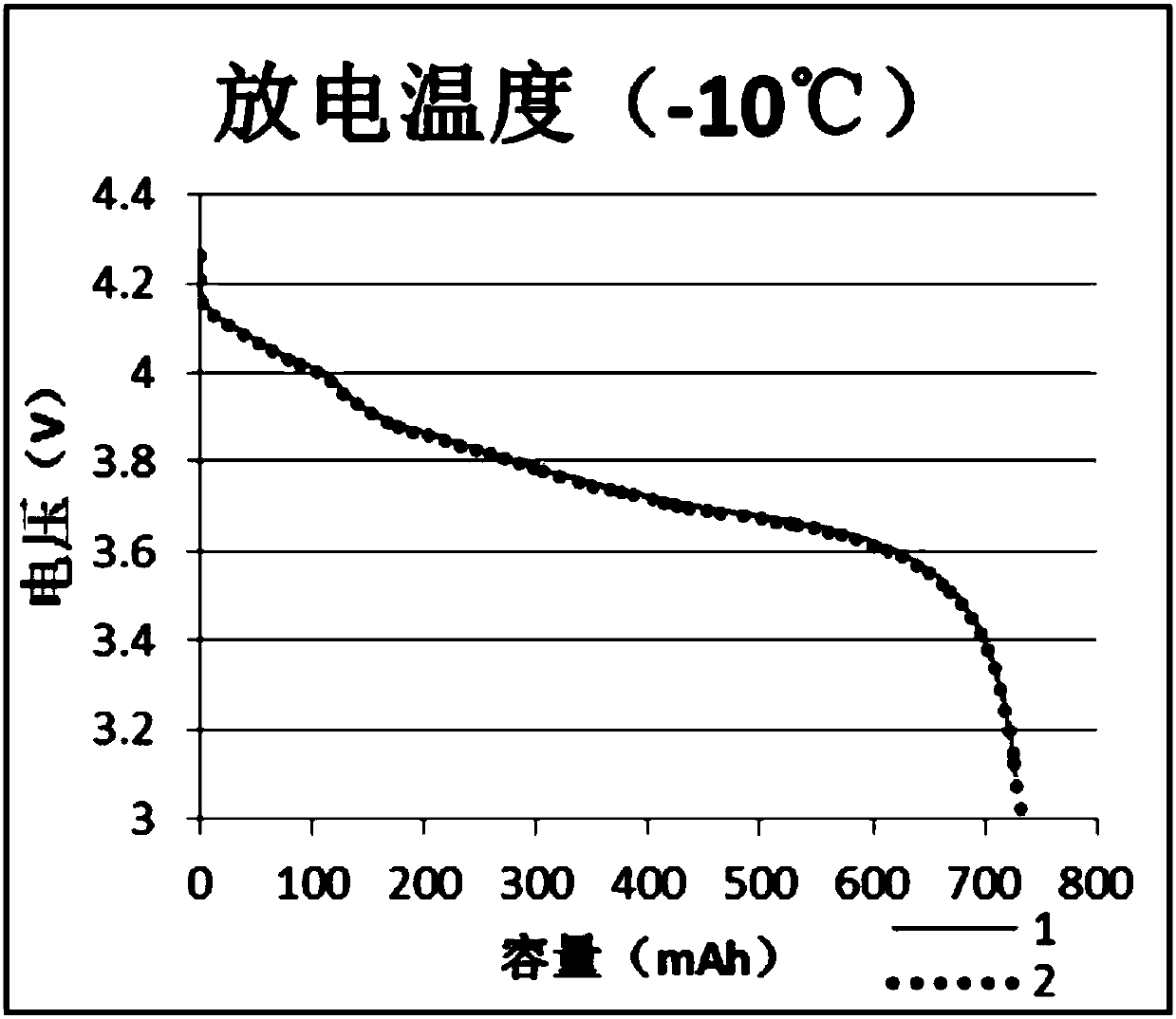

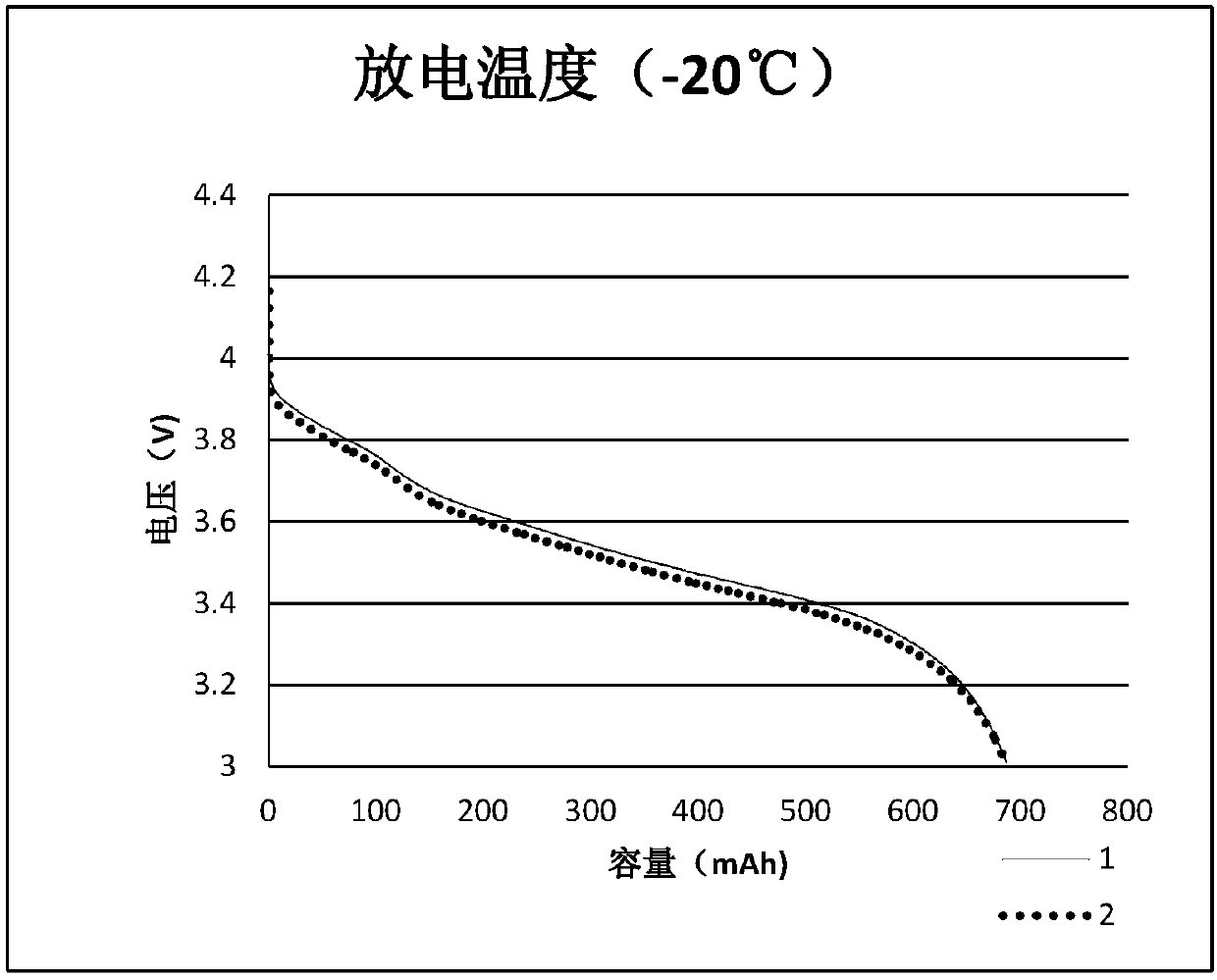

[0040] Inject the lithium-ion battery electrolyte prepared in the above steps into the fully dried 4.35V graphite / LiCoO 2 For polymer batteries (volume energy density 600W...

Embodiment 2~12 and comparative example 1~6

[0054] Examples 2 to 12 and Comparative Examples 1 to 6, except that the solvent ratio, additive composition and content (based on the total weight of the electrolyte) are added as shown in Table 1, the others are the same as in Example 1. For the formula composition of each embodiment, see Table 1, physical property data see Table 2.

[0055] Note: The lithium source in Example 1 has two parts, one part is lithium hexafluorophosphate, and the other part is lithium difluorophosphate as an additive. The amount and concentration of lithium hexafluorophosphate in Examples 2-12 and Comparative Examples 1-6 are the same as in Example 1, while the content of lithium difluorophosphate varies according to Table 1.

[0056] The formula composition of each embodiment of table 1

[0057]

[0058]

[0059]

[0060] In the above table, the abbreviated names of each chemical substance are as follows:

[0061] EC (ethylene carbonate), PC (propylene carbonate), DEC (diethyl carbona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com