Composite sol for anti-reflection coating and anti-reflection coated photovoltaic glass

A composite sol, photovoltaic glass technology, applied in the direction of colloid chemistry, colloid chemistry, coating, etc., to reduce surface roughness, improve strength and weather resistance, reduce R & D and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

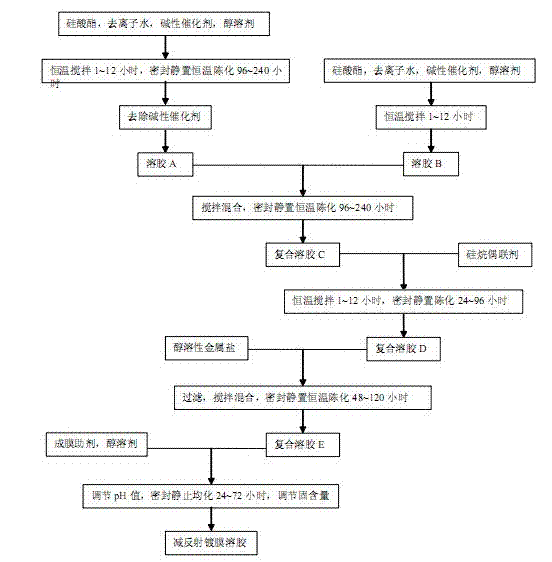

Method used

Image

Examples

Embodiment 1

[0043] A composite sol for anti-reflection coating, prepared according to the following method from the following raw materials:

[0044] Step 1: Mix ethyl orthosilicate, ethanol, ammonia water, and water at a volume ratio of 1:10:0.2:0.15, place on a magnetic stirrer and stir at 300r / min, heat to 40°C for pre-reaction 8 Hour;

[0045] Step 2: The mixed solution in step 1 was sealed and aged for 120 hours, and sol A was obtained by back distillation to remove ammonia for 6 hours;

[0046] Step 3: Take another ethyl orthosilicate, ethanol, hydrochloric acid, and water as raw materials and mix them according to the volume ratio of 1:10:0.02:0.15. Stir and pre-react at 40°C and 300r / min for 6 hours to obtain Sol B ;

[0047] Step 4: Press sol A and sol B by SiO 2 The content is mixed evenly at a ratio of 1:0.65, sealed and aged at 40°C for 48 hours to obtain composite sol C;

[0048] Step 5: Add silane coupling agent KH-550 to composite sol C at a ratio of 0.8g / L, and stir ma...

Embodiment 2

[0054] A composite sol for anti-reflection coating, prepared according to the following method from the following raw materials:

[0055] Step 1: Mix ethyl orthosilicate, isopropanol, ammonia water and water at a volume ratio of 1:10:0.3:0.15, place on a magnetic stirrer and stir at 300r / min, heat to 40°C Reaction for 8 hours;

[0056] Step 2: Seal and age the mixed solution in Step 1 at 40° C. for 120 hours, and back-distill to remove ammonia for 6 hours to obtain Sol A;

[0057] Step 3: Take another ethyl orthosilicate, isopropanol, hydrochloric acid, and water as raw materials and mix them according to the volume ratio of 1:10:0.04:0.15, and pre-react at 40°C and 300r / min for 6 hours to obtain Sol B;

[0058] Step 4: Press sol A and sol B by SiO 2 The ratio of content 1:0.25 is mixed evenly, sealed and aged at 40°C for 48 hours to obtain composite sol C;

[0059] Step 5: Add silane coupling agent KH-550 to composite sol C at a ratio of 1.2 g / L, and hydrolyze at 40°C and...

Embodiment 3

[0065] Step 1: Mix ethyl orthosilicate, isopropanol, ammonia water and water at a volume ratio of 1:10:0.25:0.15, place on a magnetic stirrer and stir at 300r / min, heat to 40°C Reaction for 8 hours;

[0066] Step 2: Seal and age the mixed solution in Step 1 at 40°C for 120 hours, and back-distill to remove ammonia for 8 hours to obtain Sol A;

[0067] Step 3: Take another ethyl orthosilicate, isopropanol, hydrochloric acid, and water as raw materials and mix them according to the volume ratio of 1:10:0.04:0.15, and pre-react at 40°C and 300r / min for 6 hours to obtain Sol B;

[0068] Step 4: Press sol A and sol B by SiO 2 The content is mixed evenly at a ratio of 1:0.25, sealed and aged at 40°C for 48 hours to obtain composite sol C;

[0069]Step 5: Add silane coupling agent KH-570 to the composite sol C at a ratio of 1.5 g / L, and stir magnetically at 40°C and 300r / min until the hydrolysis is complete;

[0070] Step 6: Place the composite sol obtained in Step 5 for static a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com