Inorganic/organic composite thin film solid-state electrolyte for lithium metal battery and preparation method of inorganic/organic composite thin film solid-state electrolyte

A lithium metal battery and solid-state electrolyte technology, applied in the direction of lithium batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve problems such as limitations, achieve rapid transportation and transfer, improve cycle stability and safety, and inhibit The effect of adverse side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

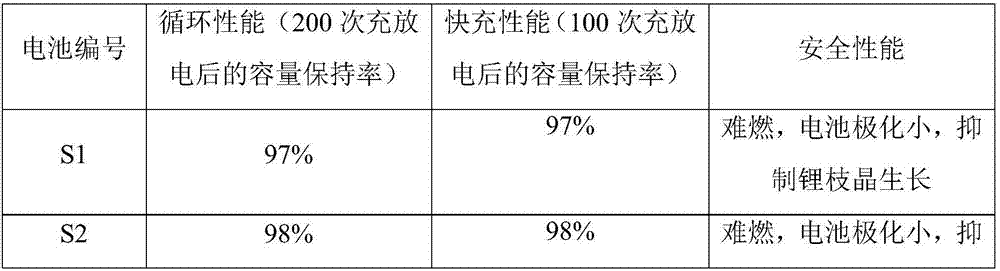

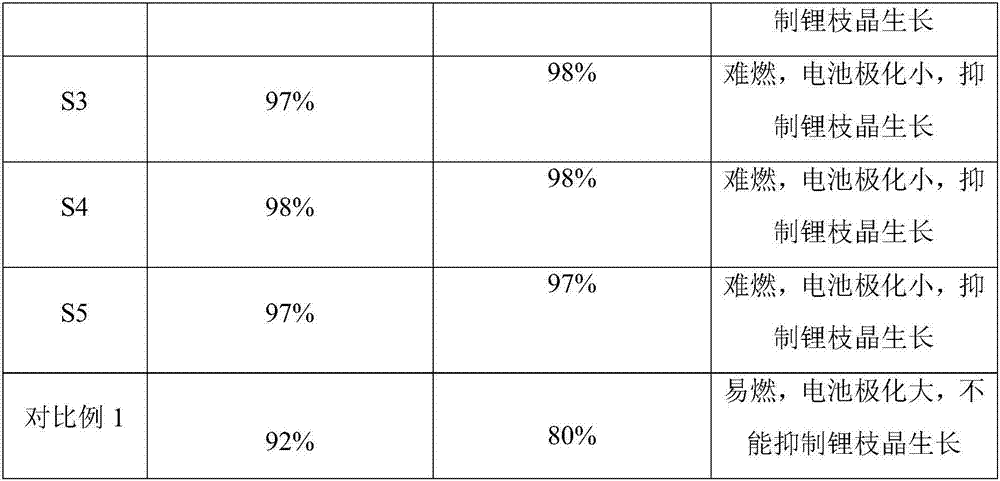

Examples

Embodiment 1

[0031] This embodiment provides an inorganic / organic composite thin-film solid electrolyte for lithium metal batteries, including a ceramic nanowire network framework, an inorganic electrolyte, and a polymer electrolyte. The inorganic electrolyte is compounded on the ceramic nanowire network framework by magnetron sputtering. , The polymer electrolyte is compounded in situ on the inorganic electrolyte and ceramic nanowire network framework.

[0032] Among them, the material of the ceramic nanowire network skeleton is Al 2 O 3 And in the solid electrolyte, the mass fraction of the ceramic nanowire network skeleton is 12%. The polymer electrolyte is polyoxyethylene, and in the solid electrolyte, the mass fraction of the polymer electrolyte is 76%, and the polymer electrolyte is uniformly compounded on the inorganic electrolyte and the ceramic nanowire network skeleton. The inorganic electrolyte is lithium lanthanum zirconium oxide (LLZO), and the inorganic electrolyte is uniformly ...

Embodiment 2

[0038] This embodiment provides an inorganic / organic composite thin-film solid electrolyte for lithium metal batteries, including a ceramic nanowire network framework, an inorganic electrolyte, and a polymer electrolyte. The inorganic electrolyte is compounded on the ceramic nanowire network framework by magnetron sputtering. , The polymer electrolyte is compounded in situ on the inorganic electrolyte and ceramic nanowire network framework.

[0039] The material of the ceramic nanowire network skeleton is MgO, and in the solid electrolyte, the mass fraction of the ceramic nanowire network skeleton is 11%. The polymer electrolyte is polyoxyethylene, and in the solid electrolyte, the mass fraction of the polymer electrolyte is 75%, and the polymer electrolyte is uniformly compounded on the inorganic electrolyte and the ceramic nanowire network skeleton. The inorganic electrolyte is lithium lanthanum zirconium oxide (LLZO), and the inorganic electrolyte is evenly distributed on the ...

Embodiment 3

[0045] This embodiment provides an inorganic / organic composite thin-film solid electrolyte for lithium metal batteries, including a ceramic nanowire network framework, an inorganic electrolyte, and a polymer electrolyte. The inorganic electrolyte is compounded on the ceramic nanowire network framework by magnetron sputtering. , The polymer electrolyte is compounded in situ on the inorganic electrolyte and ceramic nanowire network framework.

[0046] Among them, the material of the ceramic nanowire network skeleton is LiAlO 2 And in the solid electrolyte, the mass fraction of the ceramic nanowire network skeleton is 13%. The polymer electrolyte is polyoxyethylene, and in the solid electrolyte, the mass fraction of the polymer electrolyte is 74%, and the polymer electrolyte is uniformly compounded on the inorganic electrolyte and the ceramic nanowire network skeleton. The inorganic electrolyte is lithium lanthanum titanium oxide (LLTO), and the inorganic electrolyte is evenly distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com