Preparation method of composite diaphragm, composite diaphragm and lithium ion battery

A composite diaphragm and base film technology, which is applied in the field of lithium-ion batteries, can solve the problems of poor bonding effect, no pole piece bonding effect, and no diaphragm sticking, etc., and achieve the effect of improving the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

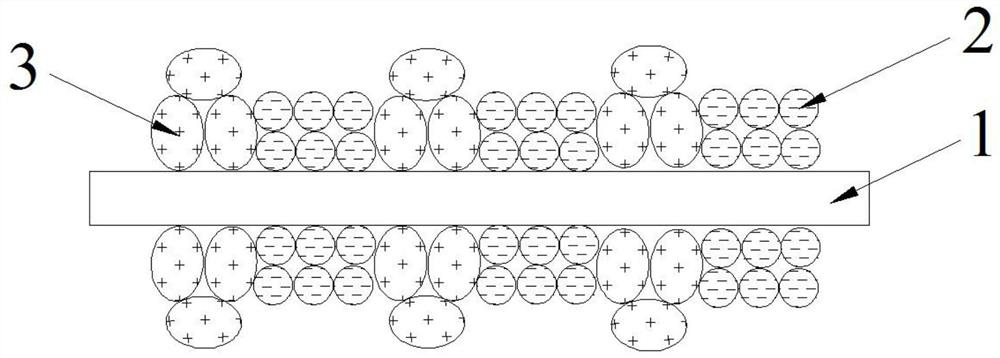

[0032] A preparation method of a composite diaphragm, comprising the following operations:

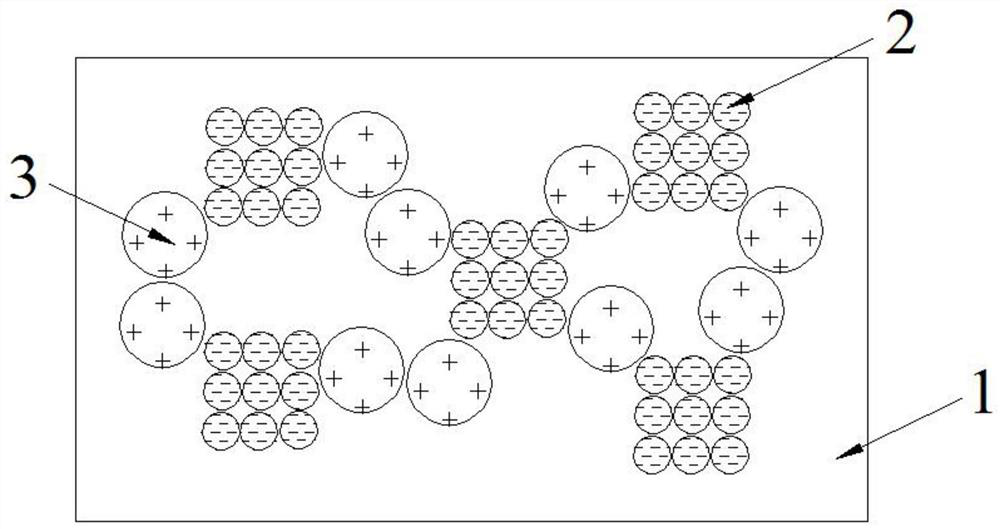

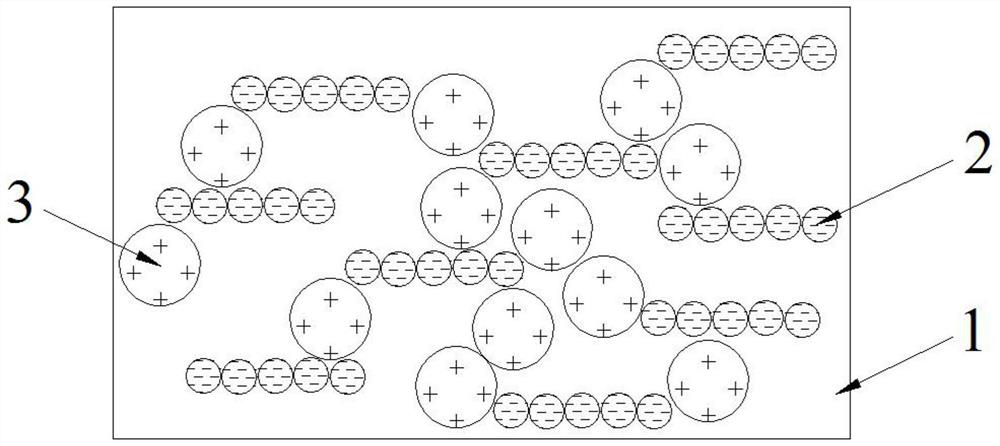

[0033] placing the inorganic particles 2 in the first solvent to obtain an inorganic slurry, coating the inorganic slurry on at least one surface of the base film 1 at intervals, and drying to obtain an inorganic thermally stable coating;

[0034]Dissolving the organic particles 3 in the second solvent to obtain an organic slurry, and coating the organic slurry on the surface of the base film 1 between the inorganic thermally stable coatings at intervals to obtain an organic bonding coating; wherein, the organic bonding The thickness of the coating is greater than that of the inorganic thermally stable coating, and a composite diaphragm is obtained after drying.

Embodiment 1

[0036] The present embodiment provides a kind of lithium ion battery, and its preparation method is:

[0037] (1) Preparation of composite diaphragm:

[0038] Take a polyethylene microporous film with a thickness of 16um as the base film;

[0039] Preparation of Inorganic Thermally Stable Coatings: Adding Al to Deionized Water 2 o 3 Particles (Al 2 o 3 The average particle size of the particles is 1 μm) and stirred for 2 hours, then ground in a ball mill for 1 hour, then added sodium carboxymethylcellulose (CMC) to the ground slurry, and continued to stir for 1 hour to prepare an inorganic slurry. The two sides of the base film are coated with inorganic slurry at intervals by gravure coating, so that the Al 2 o 3 The particles are arranged at intervals in an island shape on the surface of the base film to obtain an inorganic thermally stable coating with a thickness of 5 μm, which is ready to use after drying;

[0040] Preparation of organic bonding coating: Add polyvin...

Embodiment 2

[0046] This embodiment provides a lithium ion battery, and the difference from embodiment 1 is the preparation of the composite separator:

[0047] Take a glass fiber membrane with a thickness of 16um, dissolve the synthetic polyamic acid solution in DMAc, and then apply the mixed solution to the glass fiber membrane, first raise the temperature to 60°C and keep it for 30min; then raise the temperature to 120°C and keep it for 30min; then raise the temperature Keep at 200°C for 60 minutes, dry to remove excess solvent, and vacuum dry to complete the imidization reaction to obtain a polyimide-glass fiber composite film as the base film;

[0048] Preparation of Inorganic Thermally Stable Coatings: Adding Al to Deionized Water 2 o 3 Particles (Al 2 o 3 The average particle size of the particles is 1 μm) and stirred for 2 hours, then ground in a ball mill for 1 hour, then added sodium carboxymethylcellulose (CMC) to the ground slurry, and continued to stir for 1 hour to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com