Sticking glue for diamond wire silicon slice and preparation method

A technology for silicon slices and diamond wire, which is applied in the field of silicon slice sticky glue and preparation of diamond wire, can solve the problems of increasing the conductivity of cooling water or water used for degumming, easily damaging the cooling water circulation system, affecting production efficiency, etc. Degumming performance in boiled water, reducing the risk of chipping, and the effect of good water resistance and cutting fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

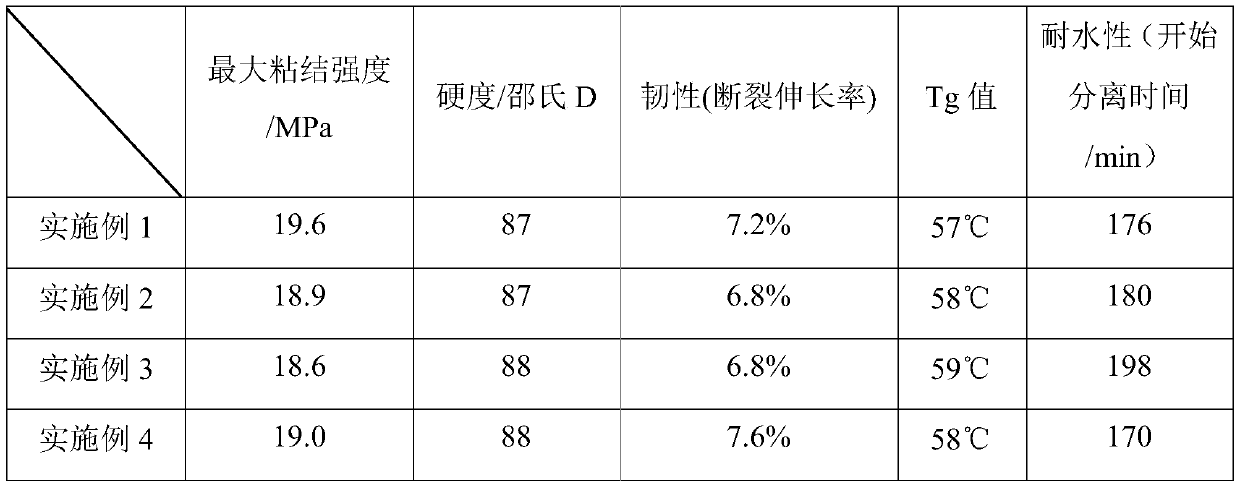

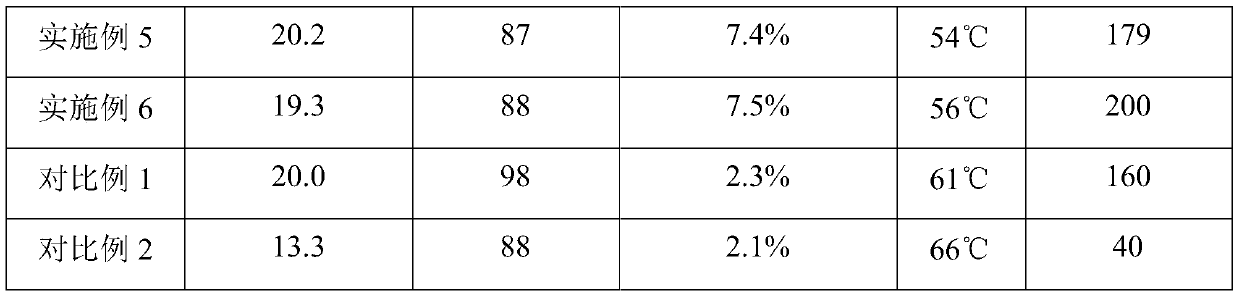

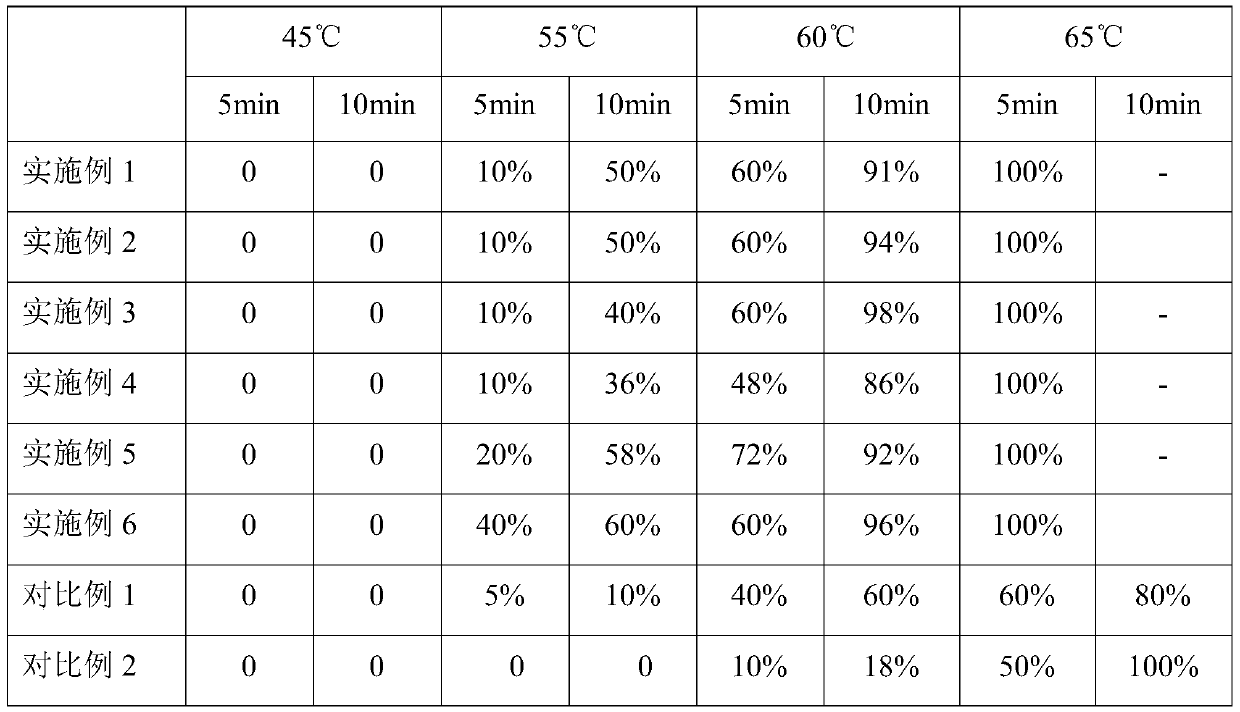

Examples

Embodiment 1

[0024] A kind of diamond wire silicon slice sticky stick glue, it comprises the following raw materials in parts by weight:

[0025] Component A: 5 parts of glycidyl ester epoxy resin, 35 parts of general-purpose bisphenol A epoxy resin, 1 part of glycidyl ether, 20 parts of filler, 0.01 part of defoamer, 0.05 part of anti-settling agent and 0.01 part of coupling agent share;

[0026] Component B: 20 parts of modified polythiol, 1 part of self-made m-xylylenediamine prepolymer, 1 part of accelerator, 20 parts of filler, 0.01 part of defoamer and 0.05 part of anti-settling agent;

[0027] Wherein, the self-made m-xylylenediamine prepolymer is the product described in the patent No. CN103665327B;

[0028] The glycidyl ester type epoxy resin is glycidyl ester S-182, the general-purpose bisphenol A epoxy resin is E55, and the glycidyl ether is lauryl glycidyl ether; the modified polythiol is polythiol 3800;

[0029] The coupling agent is KH-550, the accelerator is DMP-30, the ...

Embodiment 2

[0033] Component A: 10 parts of glycidyl ester epoxy resin, 75 parts of general-purpose bisphenol A epoxy resin, 5 parts of glycidyl ether, 60 parts of filler, 3 parts of defoamer, 5 parts of anti-settling agent and 3 parts of coupling agent share;

[0034] Component B: 50 parts of modified polythiol, 5 parts of self-made m-xylylenediamine prepolymer, 10 parts of accelerator, 40 parts of filler, 3 parts of defoamer and 5 parts of anti-settling agent.

[0035] Wherein, the self-made m-xylylenediamine prepolymer is the product described in the patent No. CN103665327B;

[0036] The glycidyl ester type epoxy resin is obtained by mixing glycidyl ester S-182 and glycidyl tertiary carbonic acid ester according to the ratio of 1:2 by mass ratio, and the general-purpose bisphenol A epoxy resin is E-51 and E55 according to the mass ratio of 1 : 1 mixed to obtain; Glycidyl ether is lauryl glycidyl ether; Modified polythiol is polythiol JH-3381;

[0037] The coupling agent is KH-570, th...

Embodiment 3

[0040] Component A: 8 parts of glycidyl ester epoxy resin, 55 parts of general-purpose bisphenol A epoxy resin, 3 parts of glycidyl ether, 48 parts of filler, 1.2 parts of defoamer, 2 parts of anti-settling agent and 1.8 parts of coupling agent share;

[0041] Component B: 30 parts of modified polythiol, 4 parts of self-made m-xylylenediamine prepolymer, 6 parts of accelerator, 34 parts of filler, 1.2 parts of defoamer and 2 parts of anti-settling agent.

[0042] Wherein, the self-made m-xylylenediamine prepolymer is the product described in the patent No. CN103665327B;

[0043] Described glycidyl ester type epoxy resin is glycidyl methacrylate, bisphenol A type epoxy resin is E-55; Glycidyl ether is 1,4 butanediol diglycidyl ether; Modified polythiol is Polymercaptan GMP-830 and GMP-888 are mixed according to the mass ratio of 1:1;

[0044] The coupling agent is KH-560, the accelerator is DMP-30, the defoamer is BYK-072, the anti-sedimentation agent is hydrogenated castor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com