A high temperature resistant water-soluble polyester size

A technology of water-soluble polyester and high temperature resistance, applied in the field of polyester size, can solve the problems of affecting the sizing effect of polyester size, easy caking, etc., achieve good adhesion, easy film formation, and improve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

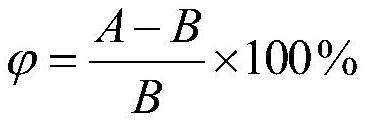

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 100 parts of polyester, 45 parts of ethylene glycol, 8 parts of sodium pentasulfonate isophthalate, 7 parts of isophthalic acid, 0.8 parts of polyether, 5 parts of diethylene glycol, 1 part of polyethylene glycol 600, 3 parts of adipic acid and 0.1 part of anti-ether agent were put into the esterification kettle, beating and mixing for 30 minutes, the temperature was controlled at 260 ° C, esterification was carried out for 3 h to obtain an esterification liquid, and then the filter was heated to 260 ° C, and the esterification liquid was poured and filtered. To the polymerization kettle, the polymerization time is less than or equal to 3h, the polymerization temperature is 270℃, and the vacuum degree is less than or equal to 100pa.

[0026] The water-soluble polyester slurry melt, cationic polyacrylamide, ammonium persulfate and urethane are introduced into the mixing kettle, and the mass ratio of the water-soluble polyester slurry melt, cationic polyacrylamide, and ure...

Embodiment 2

[0029] 100 parts of polyester, 40 parts of ethylene glycol, 9 parts of sodium pentasulfonate isophthalate, 6.5 parts of isophthalic acid, 0.9 parts of polyether, 3.5 parts of diethylene glycol, 3.5 parts of polyethylene glycol 600, 2 parts of adipic acid and 0.3 part of anti-ether agent were put into the esterification kettle, beating and mixing for 30 minutes, the temperature was controlled at 250 ° C, esterification was carried out for 3.5 h to obtain an esterification liquid, and then the temperature of the filter was raised to 260 ° C, and the esterification liquid was poured Filter to the polymerization kettle, the polymerization time is less than or equal to 3h, the polymerization temperature is 270℃, and the vacuum degree is less than or equal to 100pa.

[0030] The water-soluble polyester slurry melt, cationic polyacrylamide, potassium persulfate and urethane are introduced into the mixing kettle, and the mass ratio of the water-soluble polyester slurry melt, cationic p...

Embodiment 3

[0033] 100 parts of polyester, 35 parts of ethylene glycol, 10 parts of sodium pentasulfonate isophthalate, 6 parts of isophthalic acid, 1 part of polyether, 2 parts of ethylene glycol, 6 parts of polyether glycol 400, 1 part of polyester polyol and 0.5 part of anti-ether agent were put into the esterification kettle for beating and mixing for 30min, the temperature was controlled at 240°C, esterification was carried out for 4h to obtain an esterification liquid, then the temperature of the filter was increased to 260°C, and the esterification liquid was poured into The material is filtered into the polymerization kettle, the polymerization time is less than or equal to 3h, the polymerization temperature is 270℃, and the vacuum degree is less than or equal to 100pa.

[0034] The water-soluble polyester slurry melt, cationic polyacrylamide, hydrogen peroxide and urethane are introduced into the mixing kettle, and the mass ratio of the water-soluble polyester slurry melt, cationi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com