Repairable single-component epoxy structural adhesive and preparation method thereof, and application of repairable single-component epoxy structural adhesive

An epoxy structural adhesive, one-component technology, applied in the field of electronic adhesives, can solve the problems of difficult repair of one-component epoxy structural adhesives, and achieve the effects of reduced bond strength, reduced Tg value, and good storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

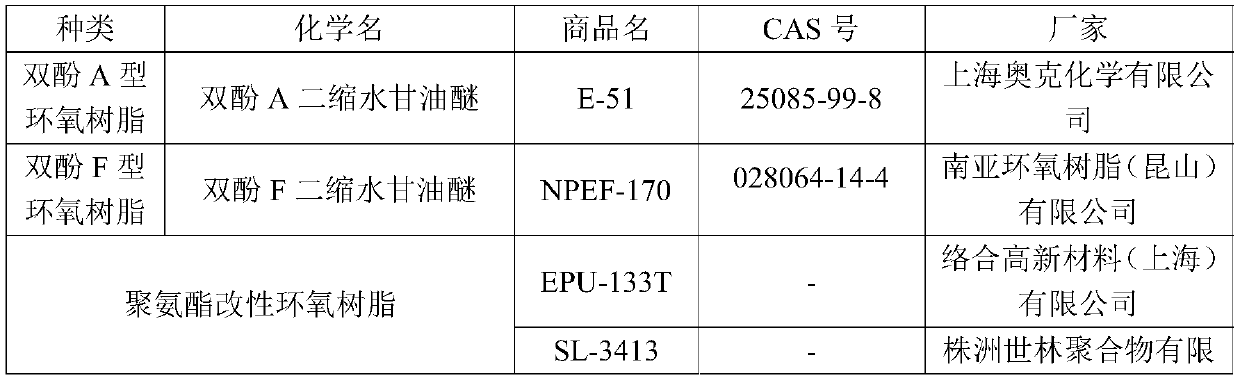

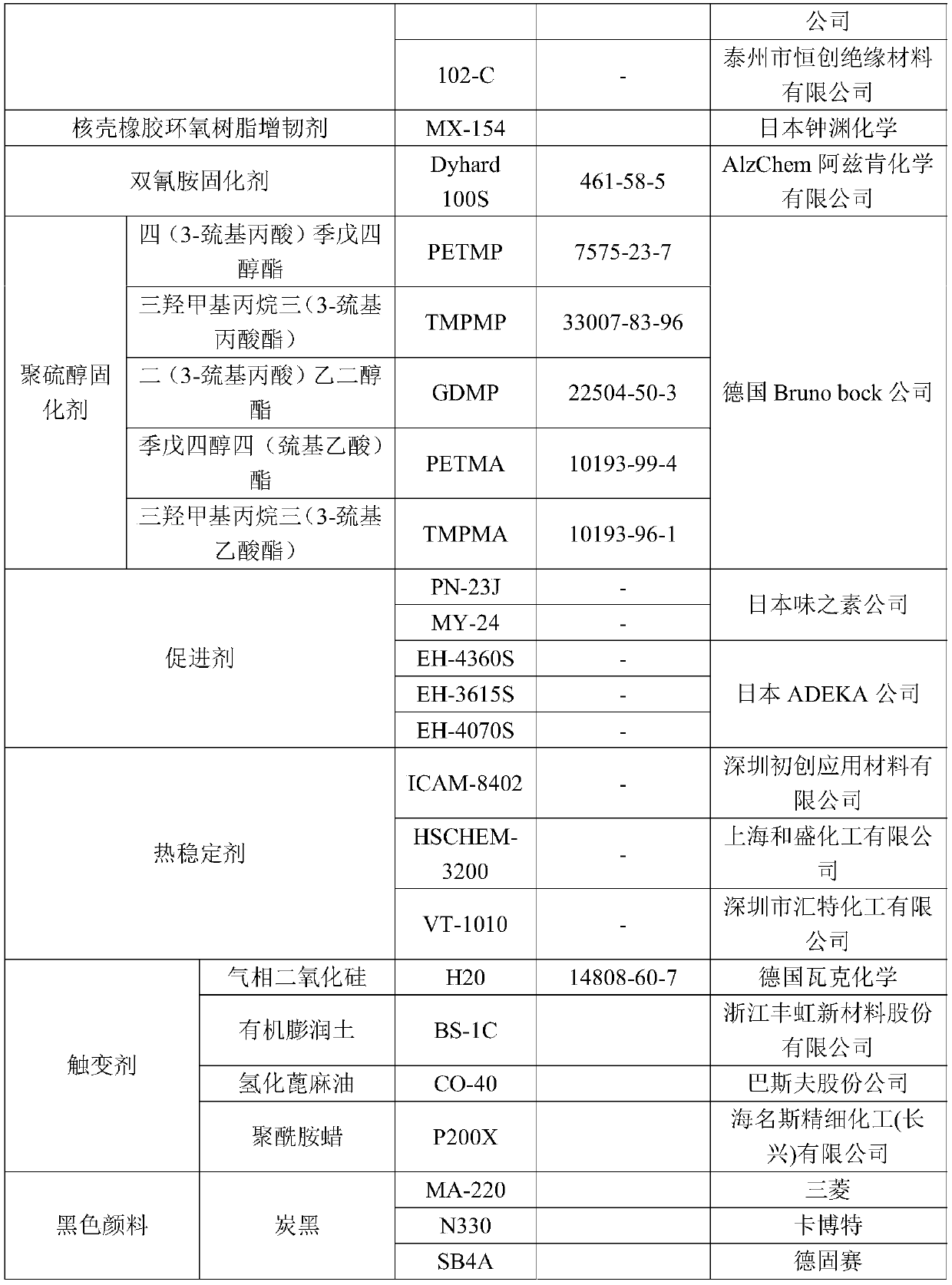

Method used

Image

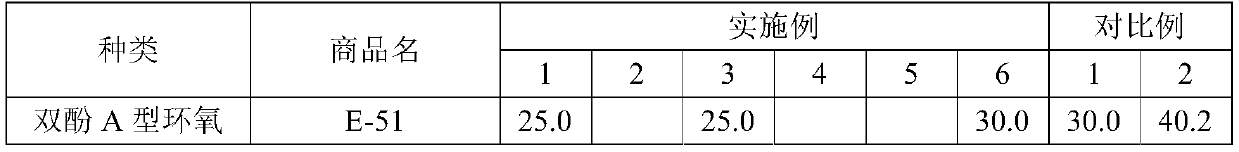

Examples

preparation example Construction

[0033] The preparation method of the epoxy structural glue of embodiment 1~6

[0034] Add bisphenol A or F epoxy resin, polyurethane modified epoxy resin, polythiol curing agent, heat stabilizer, thixotropic agent and black pigment to the double planetary mixer (Taiyi (Shanghai) Industrial Co., Ltd. Co., Ltd., model TSJ-5) in the stainless steel kettle, first open the circulating condensed water in the jacket of the kettle wall, and then open the mechanical stirring and high-speed dispersion plate. By adjusting the temperature and flow rate of the condensed water, the temperature of the material in the kettle is controlled not to exceed 30°C (the cooling water temperature and flow rate are adjusted according to the actual temperature in the kettle, if the temperature in the kettle is high, the temperature of the cooling water should be lowered, or the flow rate should be accelerated. Speed up the heat dissipation and ensure that the temperature of the material in the kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com