OCA (Optical Clear Adhesive) as well as preparation method and application thereof

A film and resin technology, applied in the field of optical glue, can solve the problems of insufficient performance of adhesion and recovery of deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

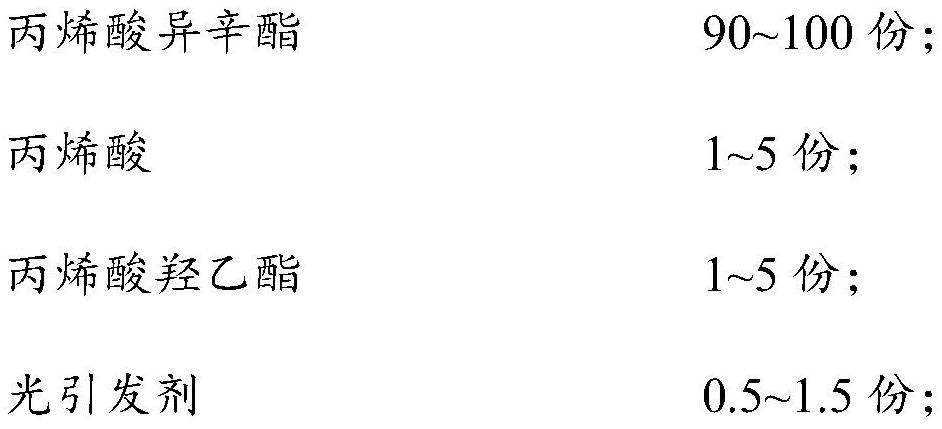

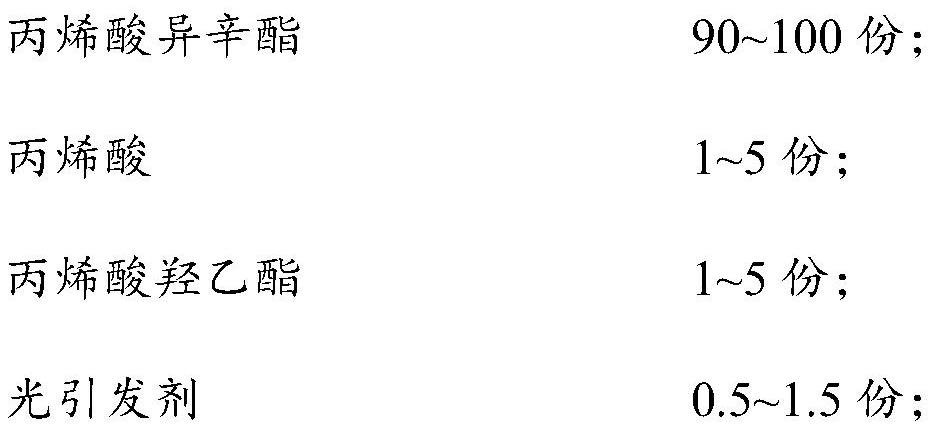

Method used

Image

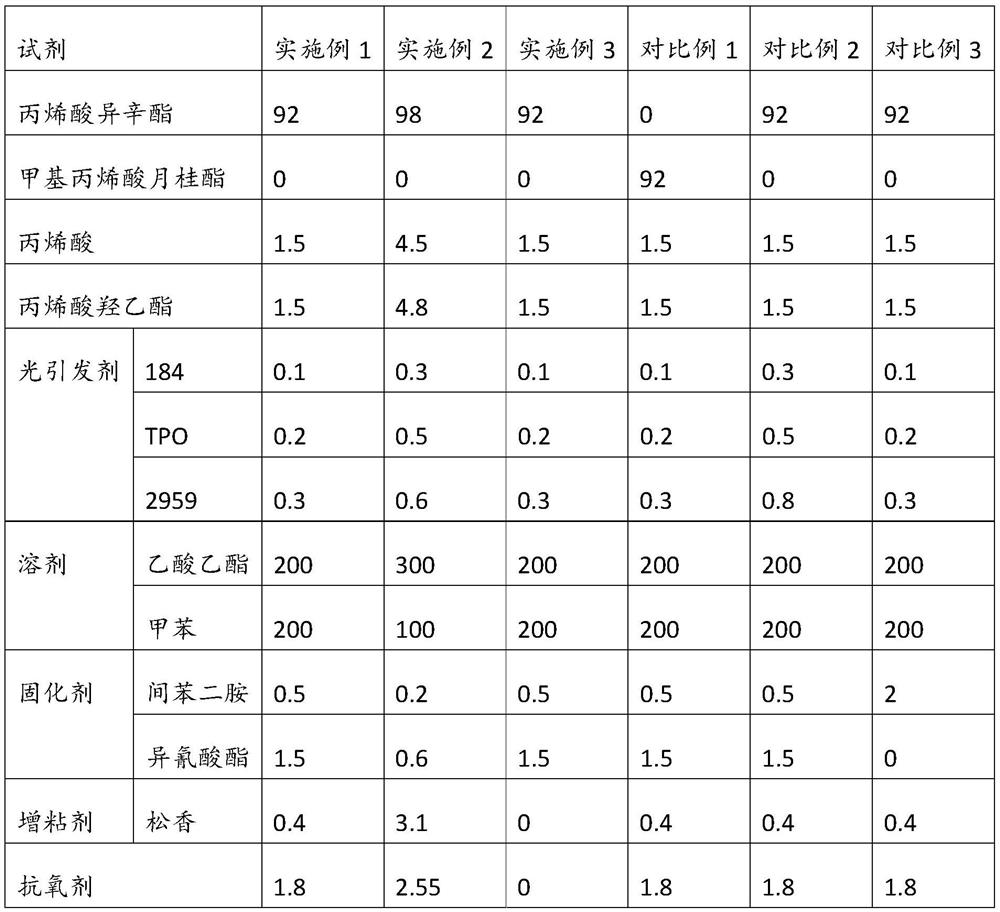

Examples

Embodiment 1

[0081] The present embodiment prepares a kind of OCA glue, and the specific process is:

[0082] S1. Control the ambient temperature to 15°C, dissolve the photoinitiator in the solvent, then add a mixture of isooctyl acrylate, acrylic acid and hydroxyethyl acrylate to it, stir evenly, and use a light intensity of 8W / m 2 The resulting mixed system is irradiated with a mercury lamp (main peak wavelength 250nm), and the irradiation is stopped after the weight-average molecular weight of the obtained product is > 2 million (while the molecular weight needs to be controlled < 3 million, the weight-average molecular weight of the acrylate resin obtained in this example is about 230 Ten thousand);

[0083] S2. Control the temperature of the mixture obtained in step S1 to be 10-15°C, and under stirring at 300 rpm, add curing agent, tackifier and antioxidant to the mixture obtained in step S1 in sequence, and then continue to stir for 10 min.

[0084] Unless otherwise specified, in th...

Embodiment 4

[0088] A kind of OCA glue is prepared in this example, and the difference between the specific process and Example 1 is:

[0089] (1) In step S1, the light intensity of the mercury lamp is 45W / m 2 ; Correspondingly, the weight-average molecular weight of the obtained acrylate resin is about 2.01 million.

Embodiment 5

[0091] This embodiment prepares a kind of OCA film, and the specific process is:

[0092] D1. Using extrusion coating method, coat the OCA adhesive obtained in Example 1 on the surface of the PET release film with a thickness of 50 μm; cover the surface of the newly coated OCA adhesive with a layer of PET release film; the coating thickness is : Design OCA film thickness 15μm;

[0093] D2. The light intensity is 400W / m 2 The mercury lamp (main peak wavelength 250nm) irradiates the product obtained in step S1 for 1min;

[0094] D3. Send the parts obtained in step D2 into a flat plate hot press, apply a pressure of 0.1 MPa, and cure at 90° C. for 3 minutes.

[0095] The thickness of the OCA film (only the OCA film layer) obtained in this example is about 15.1 μm (the average value is obtained after testing 10 points with a micrometer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com