Special rubber for snow tires

A snow tire and rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of loss of work ability and safety, increased tire hardness, poor cold resistance, etc., to achieve excellent cold resistance, improve Cold resistance, the effect of good cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

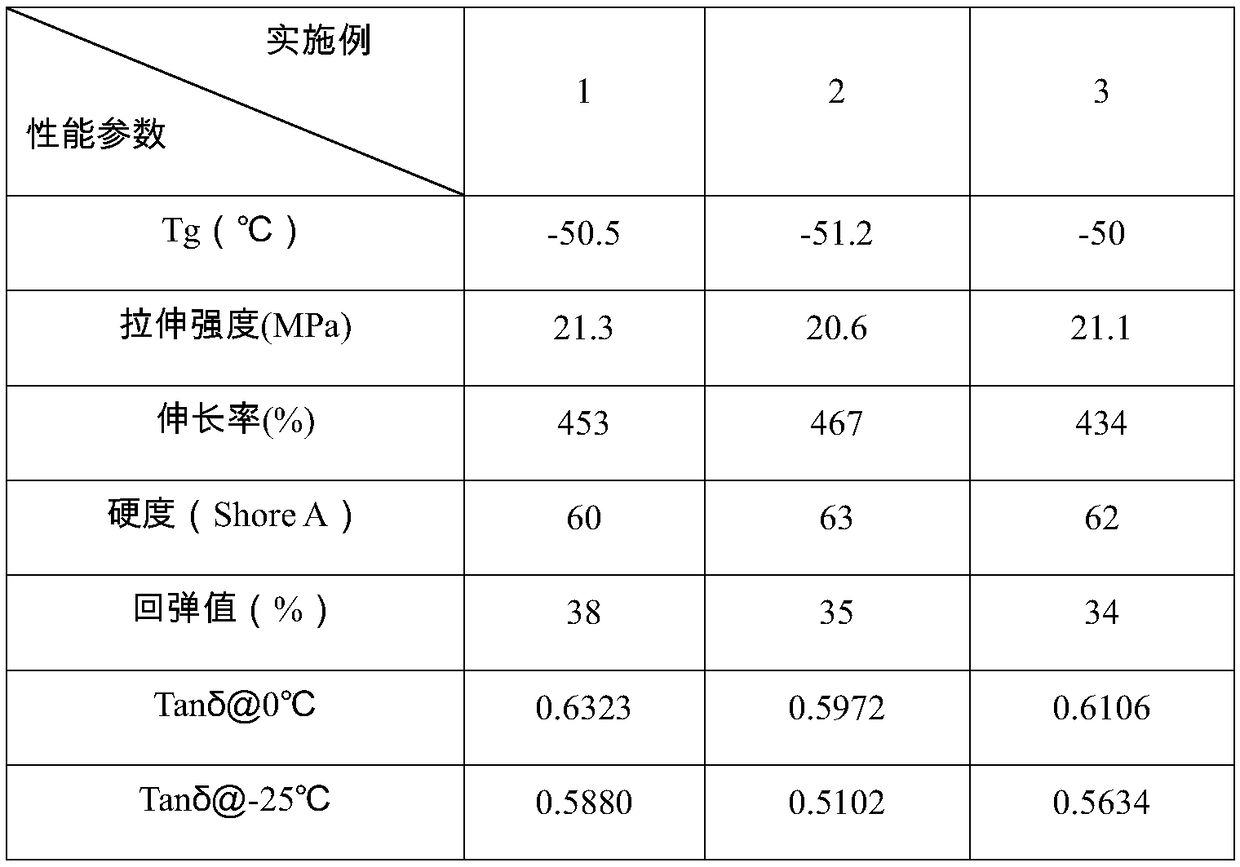

Examples

Embodiment 1

[0023] A special rubber for snow tires, comprising the following components in parts by mass: 60 parts of natural rubber, 30 parts of butadiene rubber, 10 parts of epichlorohydrin rubber, 35 parts of carbon black N330, 15 parts of carbon black N339, 12 parts of white carbon Black, 8 parts of silane coupling agent Si75, 5 parts of zinc stearate soap, 4 parts of aromatic oil, 1 part of antioxidant D, 1.5 parts of antioxidant H, 1 part of bis-2,4, 3 parts of bis-2,5 , 2 parts of accelerator TT, 1 part of accelerator D, 2 parts of accelerator NS.

[0024] The special rubber for snow tires is prepared according to the following steps:

[0025] 1. Add natural rubber, butadiene rubber, chloroether rubber, 1 / 2 of carbon black N330, 1 / 2 of carbon black N339, antioxidant H, into the internal mixer, and mix for 3 minutes;

[0026] 2. Add the remaining carbon black and white carbon black, silane coupling agent Si75, aromatic hydrocarbon oil, and zinc stearate soap to the above system, an...

Embodiment 2

[0031] A special rubber for snow tires, comprising the following components in parts by mass: 50 parts of natural rubber, 35 parts of butadiene rubber, 15 parts of epichlorohydrin rubber, 25 parts of carbon black N330, 20 parts of carbon black N339, 12 parts of white carbon Black, 5 parts of silane coupling agent Si75, 3 parts of zinc stearate soap, 2 parts of aromatic oil, 2 parts of antiaging agent D, 0.5 parts of antiaging agent H, 3 parts of bis-2,4, 1 part of bis-2,5 , 1 part of accelerator TT, 2 parts of accelerator D, 1 part of accelerator NS.

[0032] The preparation method is the same as the previous embodiment.

Embodiment 3

[0034] A special rubber for snow tires, comprising the following components in parts by mass: 65 parts of natural rubber, 25 parts of butadiene rubber, 10 parts of epichlorohydrin rubber, 45 parts of carbon black N330, 15 parts of carbon black N339, 18 parts of white carbon Black, 6 parts of silane coupling agent Si75, 4 parts of zinc stearate soap, 5 parts of aromatic oil, 1 part of antioxidant D, 1 part of antioxidant H, 2 parts of bis-2,4, 2 parts of bis-2,5 , 1 part of accelerator TT, 1 part of accelerator D, 2 parts of accelerator NS.

[0035] The preparation method is the same as the previous embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com