Texture coating and preparation method thereof

A texture paint and pigment technology, applied in the direction of coating, etc., can solve the problems of loss of cohesion, affecting the spraying effect of texture paint, sand falling and flying sand in the coating film, etc., to reduce the amount of addition, uniform appearance, and high viscosity increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

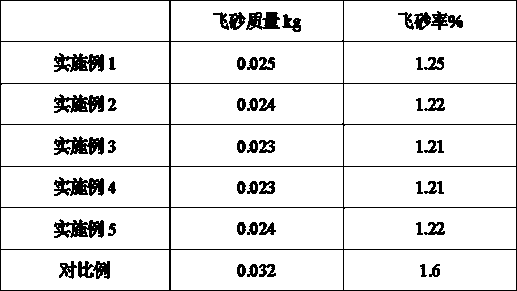

Examples

preparation example Construction

[0033] A kind of preparation method of texture coating, described preparation method comprises the following steps:

[0034] (1) Adjust the stirring speed to 200-500r / min, add water, modified cellulose, dispersant, defoamer, pigment, alcohol ester twelve film-forming aids, ethylene glycol, silicon acrylic emulsion to the reactor , elastic emulsion, inorganic thixotropic thickener, anti-mildew bactericide and redispersible rubber powder, after adding, adjust the speed to 800-1000r / min, and continue to stir for 20-30min;

[0035] (2) Adjust the stirring speed to 300-600r / min, add round sand, bentonite, and calcined kaolin to the reaction kettle, adjust the speed to 800-1000r / min, and then adjust the pH value to below 10 with ammonia water; continue stirring 20-30min to get texture paint.

Embodiment 1

[0037] A kind of texture paint, its composition by mass is as follows: 100 parts of water, 1.2 parts of modified cellulose, 1.5 parts of dispersant, 0.8 part of defoamer, 15 parts of pigment, 8 parts of alcohol ester twelve film-forming aids, ethylene glycol 10 parts of alcohol, 150 parts of silicone acrylic emulsion, 50 parts of elastic emulsion, 500 parts of round sand, 30 parts of bentonite, 10 parts of calcined kaolin, 12 parts of redispersible rubber powder, 4 parts of inorganic thixotropic thickener, anti-mold and fungicide 0.8 servings.

[0038] Wherein, the modified cellulose is selected from microcrystalline cellulose.

[0039] Among them, the dispersant is a mixture of sodium phosphate and sodium tripolyphosphate, and its mass ratio is 1:1.

[0040] Among them, the particle size of round sand is 40-100 mesh, and the proportion of 80 mesh or less accounts for 80%.

[0041] Among them, ATT-50 is selected as the inorganic thixotropic thickener.

[0042] Among them, t...

Embodiment 2

[0048] A kind of texture paint, its composition by mass is as follows: 120 parts of water, 1.3 parts of modified cellulose, 1.8 parts of dispersant, 0.8 part of defoamer, 16 parts of pigment, 8 parts of alcohol ester twelve film-forming aids, ethylene glycol 12 parts of alcohol, 150 parts of silicone acrylic emulsion, 60 parts of elastic emulsion, 550 parts of circular sand, 40 parts of bentonite, 12 parts of calcined kaolin, 12 parts of redispersible rubber powder, 4 parts of inorganic thixotropic thickener, anti-mold and fungicide 0.8 servings.

[0049] Among them, the modified cellulose is selected from cellulose inorganic acid ester.

[0050] Among them, the dispersant is a mixture of sodium phosphate and sodium tripolyphosphate, and its mass ratio is 1:1.2.

[0051] Among them, the particle size of round sand is 40-100 mesh, and the proportion of 80 mesh or less accounts for 80%.

[0052] Among them, ATT-50 is selected as the inorganic thixotropic thickener.

[0053] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com