Blasting processing method for underground hanging arch

A treatment method and detonation bomb technology, applied in blasting and other directions, can solve problems such as medium and deep hole damage, residual explosives, impact, etc., and achieve the effect of reducing equipment production costs, reducing impact, and safe and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Embodiment: The blasting treatment method of the underground suspended roof is specifically described as follows.

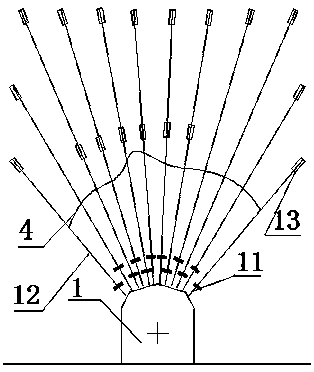

[0015] Heishan Iron Mine in Chengde, Hebei adopts the sub-level caving method without pillars. The section height is 12 meters, and the distance between the routes is 15 meters. The Simba1254 electro-hydraulic rock drilling jumbo is used as the main rock drilling equipment. 45°~60°, the hole bottom distance is 2m~3m. The BQF-100 chargeer is used for the blasting charge, and the explosive is modified ammonium oil explosive, and 1 to 2 rows of medium and deep holes are blasted each time according to the nature of the ore rock.

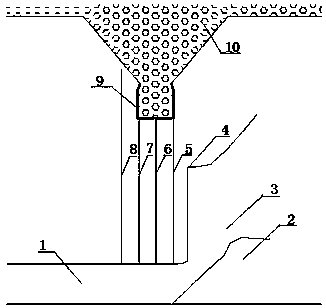

[0016] figure 1 It is the section drawing of No. 12 access road at the level of 600m underground. figure 1 As shown, the back end of the mining roadway 1 of the 600m horizontal No. 12 approach is the caving and blasting pile 2, and the space above the caving and blasting pile 2 is the empty area 3; figure 1 As shown, the suspende...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com