Hydrocarbon fire resistant ultrathin expanded fireproof coating and preparation method thereof

A fire retardant coating, intumescent technology, used in fire retardant coatings, antifouling/underwater coatings, epoxy resin coatings, etc. problems, to achieve the effect of saving coating energy, low construction cost and excellent fire protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

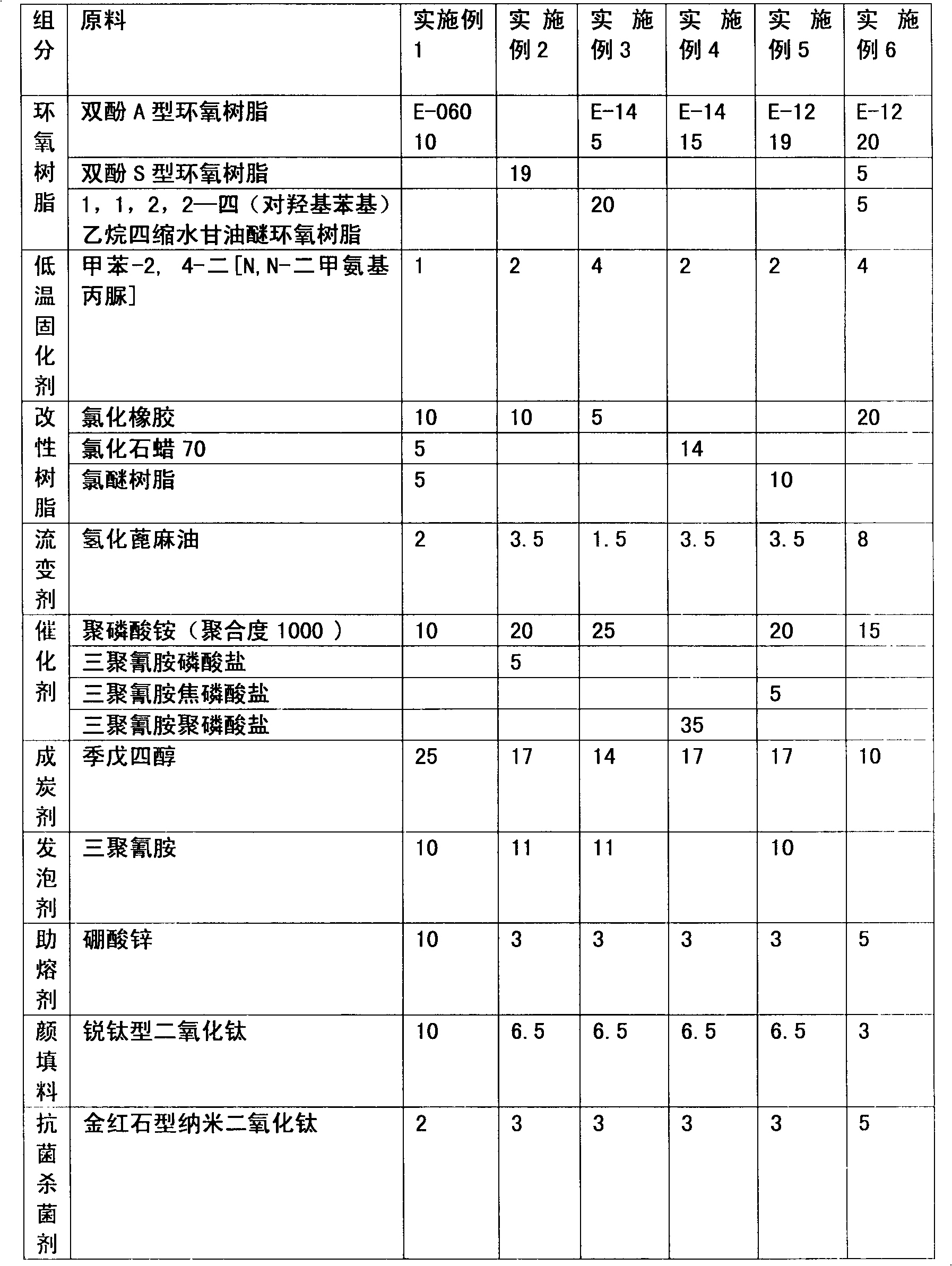

Examples

Embodiment Construction

[0019]

[0020] The preparation method is to first crush the epoxy resin and the modified resin to 35 μm, add the remaining components and mix them evenly, and extrude them with an extruder (extrusion temperature 95°C, speed 300rpm), and the obtained extruded sheets are cooled to room temperature , pulverized, and crossed a 40-mesh sieve to obtain the fireproof coating of the present invention.

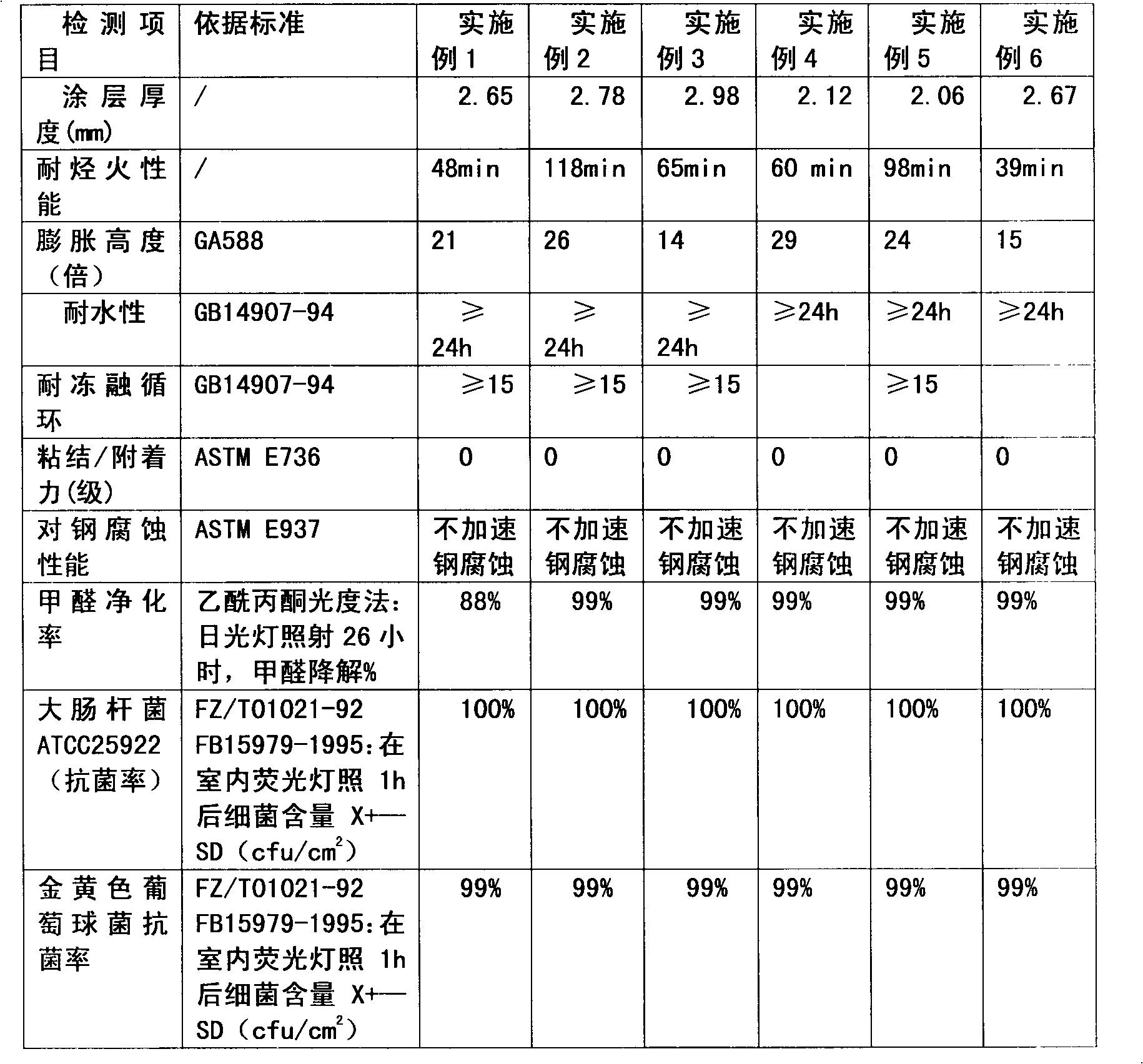

[0021] Apply electrostatic spraying on the preheated test panel, the baking temperature of the coating film is 130°C, the baking time is 10min, and the coating thickness is controlled at 3mm. The test plate was tested after being placed in a constant temperature and humidity chamber for 24 hours. Its performance indicators are shown in Table 1.

[0022] Table 1: Example performance index table

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com