Enhanced composite polyethylene double wall twined pipe and production method thereof

A reinforced composite and polyethylene technology, which is applied in the pipeline field, can solve the problems of poor light aging resistance, poor dimensional stability, and low heat resistance temperature, and achieve the effects of reducing shrinkage, improving toughness and rigidity, and increasing cooling molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

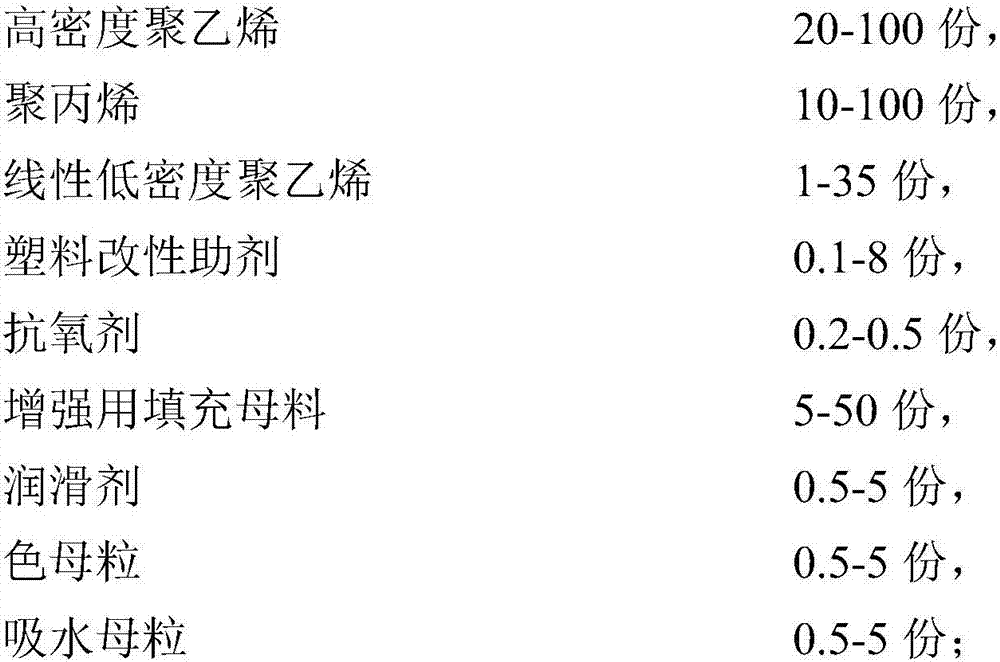

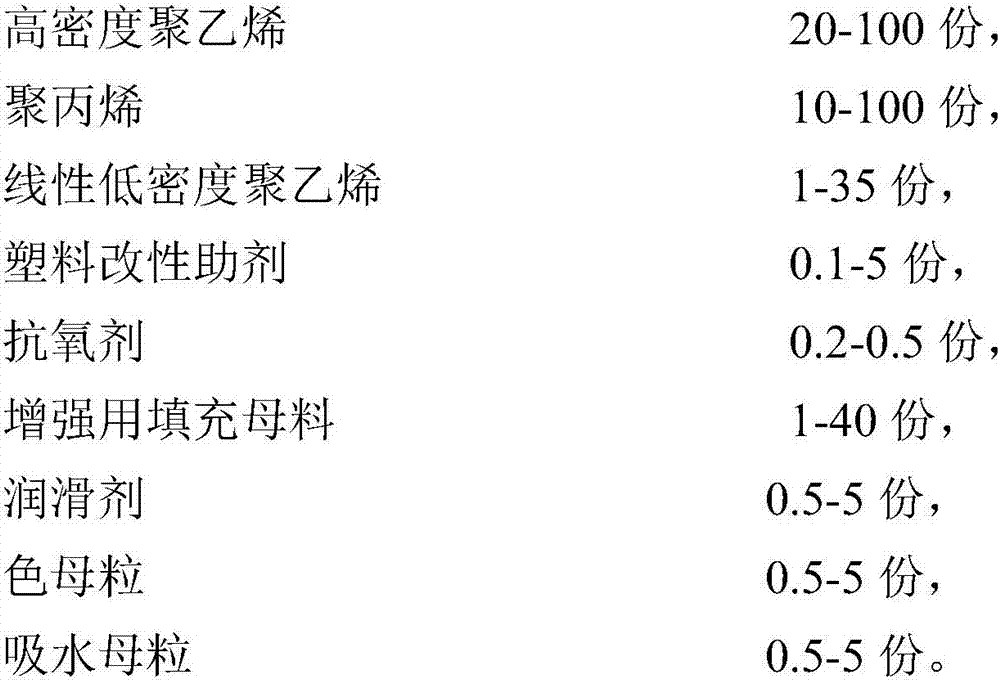

Method used

Image

Examples

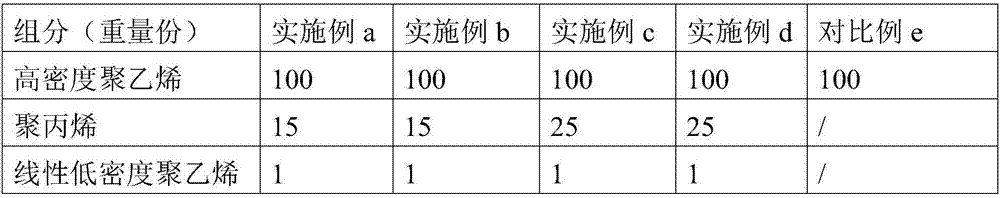

Embodiment a-d

[0032] According to the formula, the ingredients are weighed and put into a mixer for mixing and stirring to obtain the mixture for preparing the composite polyethylene hollow rectangular tube and the adhesive tape respectively;

[0033] The composite polyethylene hollow rectangular tube mixture is put into a conical twin-screw extruder, the screw temperature is controlled within the range of 180-230 ° C, and the reinforced composite polyethylene hollow rectangular tube is obtained through die extrusion and vacuum cooling;

[0034] Put the adhesive tape mixture into the adhesive tape extruder and extrude the adhesive tape, spirally wind the composite polyethylene hollow rectangular tube in step B on the pipe forming winding disk, and simultaneously After the strips are bonded, cooled, formed and cut, the reinforced composite polyethylene double-wall wound pipe is obtained.

[0035] Table 1: The formula of each raw material of composite polyethylene hollow rectangular pipe in e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com