Method for reducing residual stress of high-slenderness-ratio arc-shaped fillet opened aluminum alloy forge pieces

A technology with large slenderness ratio and residual stress, which is applied in the field of material science and engineering, can solve the problems of reducing the residual stress of alloys, achieve the effects of reducing residual stress, ensuring consistency, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

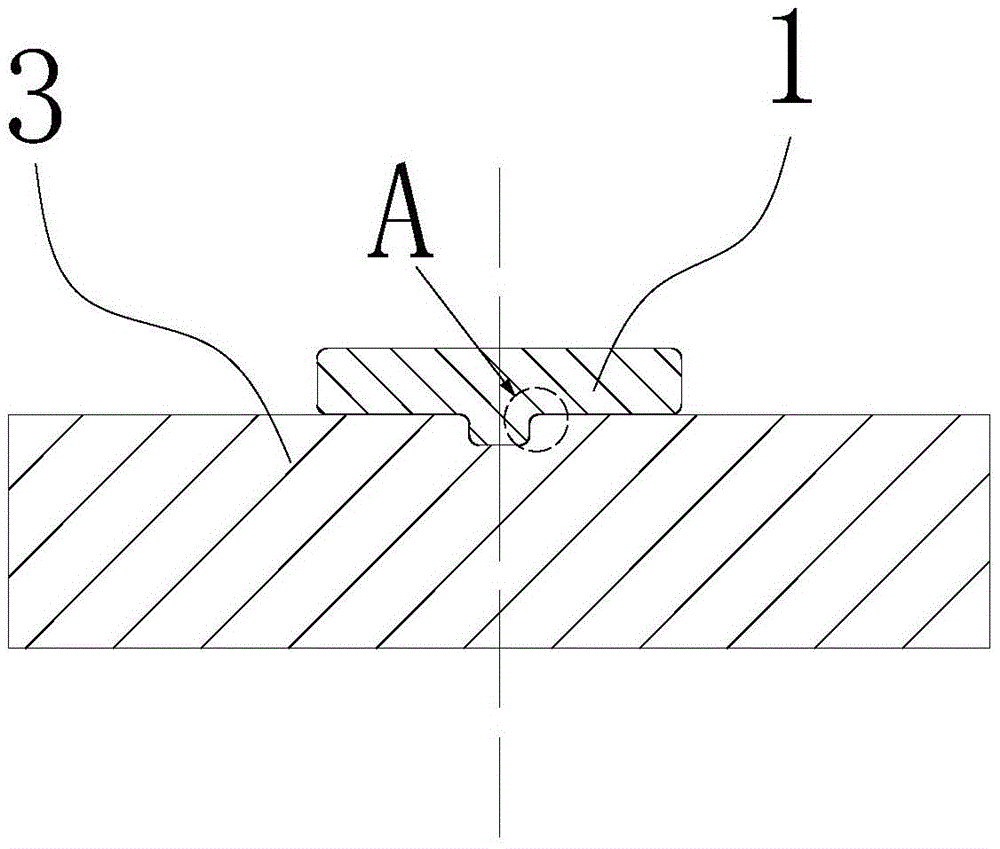

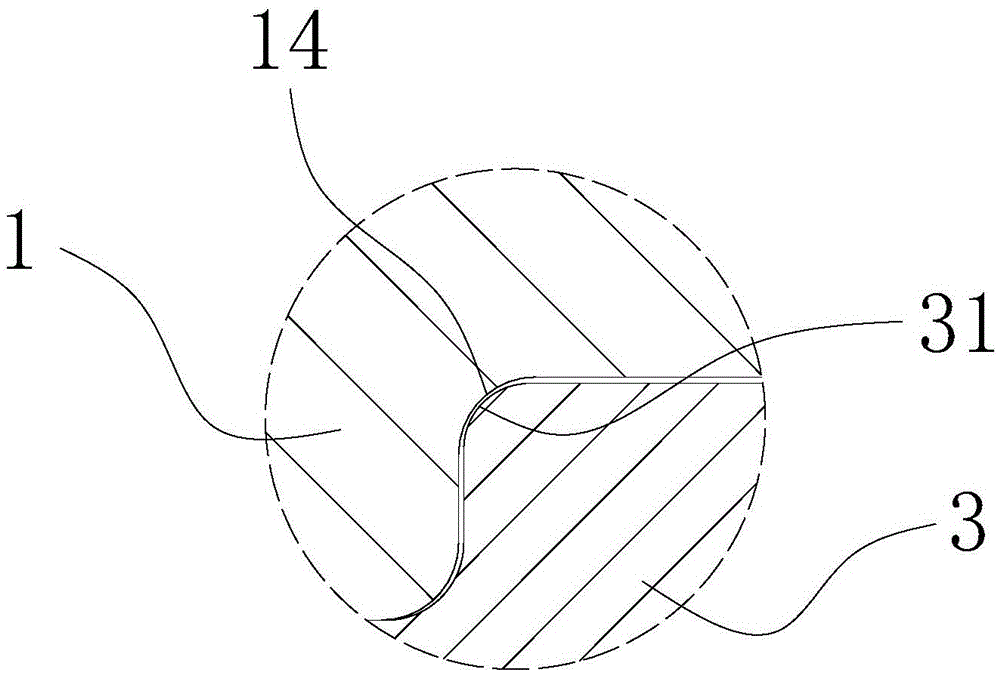

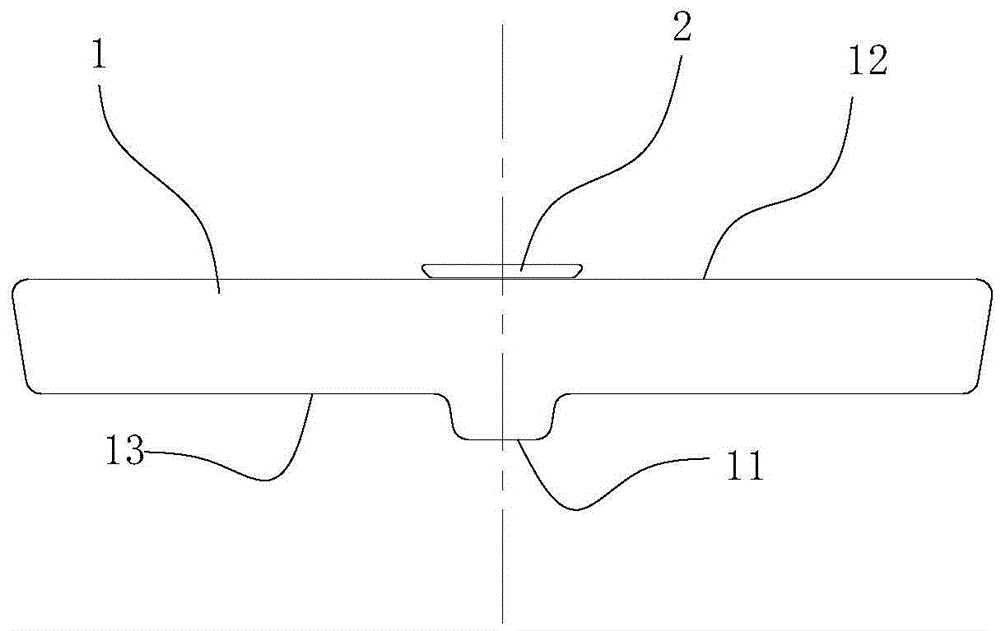

[0051] In this example, the material of the forging is 7050 aluminum alloy, the outline is 6100×700×120mm, the thickness of the web is 80mm, the thickness of the rib is 40mm, the width of the rib is 65mm, the radius of the concave fillet of the rib is 22mm, and the arc of the forging is is 27489mm, and the net projected area of the forging is 4.27m 2 . The radius of the cold pressing die convex fillet 31 is 20 mm.

[0052] In this embodiment, the cold-pressed steel plate is 45# steel plate, and the steel plate size is 6300×130×10 mm. The purpose of the steel plate width of 120mm is to cover the ribs and the concave fillets on both sides when the ribs are pressed for the first time and the last time.

[0053] The production of the method for reducing the residual stress of aluminum alloy large slenderness ratio arc-shaped rib opening type forgings according to the present invention specifically includes the following steps:

[0054] Step 1: If image 3 As shown, first pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com