Running operation method of steam power system

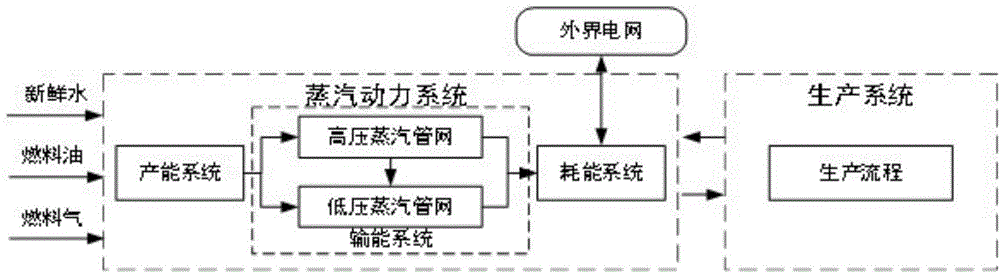

A technology of a steam power system and an operation method, which is applied in the field of operation and operation of a steam power system, can solve problems such as single function of a steam turbine, increased environmental cost, and failure to consider the influence of environmental factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

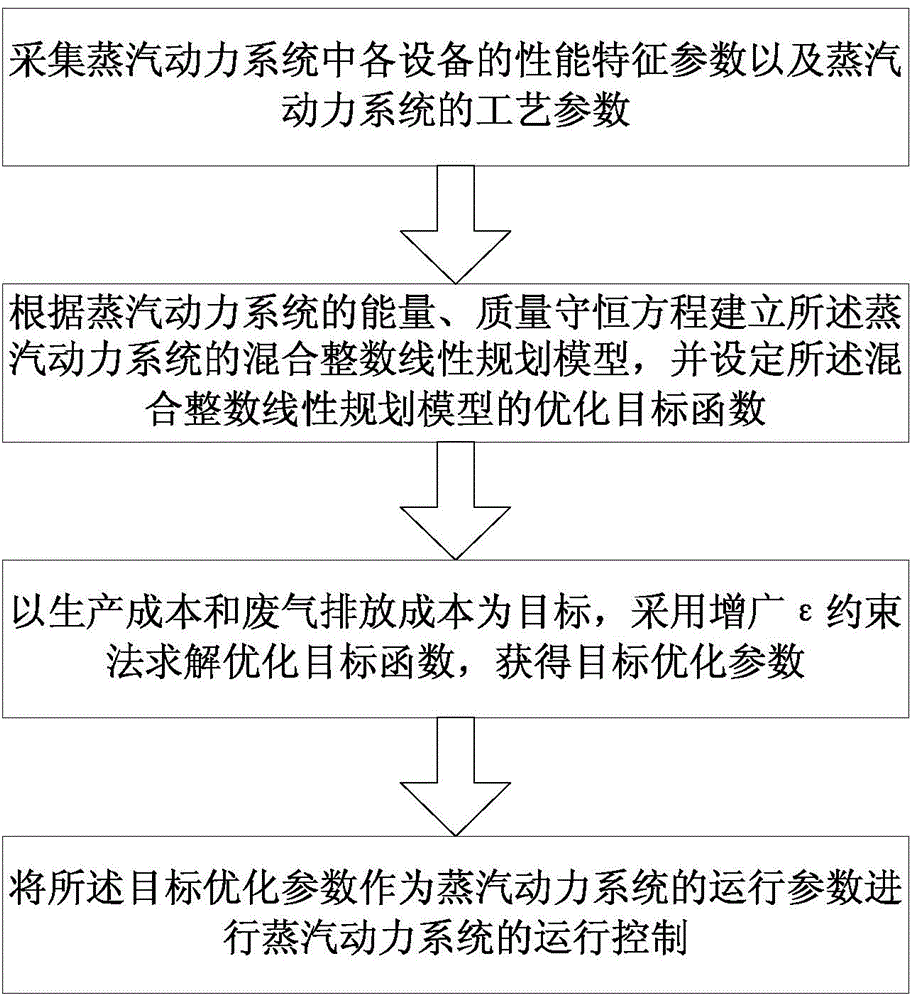

Method used

Image

Examples

Embodiment example 1

[0130] Optimize the operation method for the steam power system of a chemical enterprise.

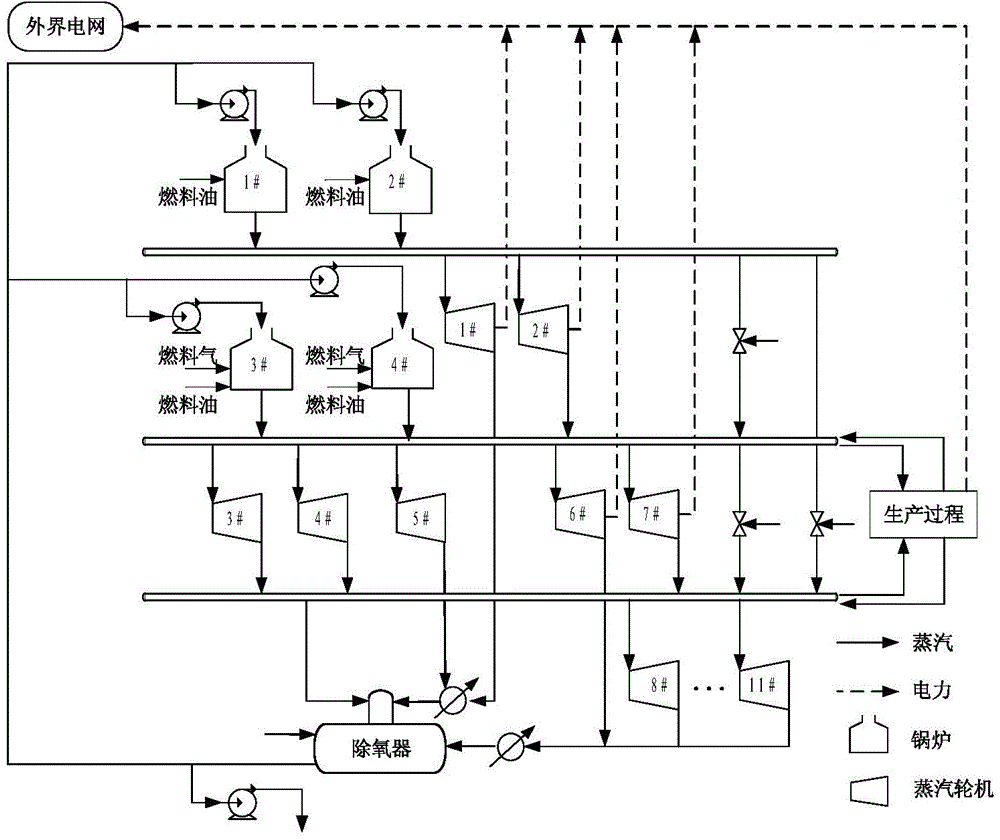

[0131] Such as image 3 As shown, the steam power system includes three different grades of steam pipe networks. The steam in the above steam pipe networks are: high-pressure steam (9.20MPa, 527°C), medium-pressure steam (3.61MPa, 433°C) and low-pressure steam (1.10MPa, 333°C). The entire steam power system is supplied with steam by 4 boilers (production equipment), among which, 1# and 2# boilers are used to produce high-pressure steam and only consume fuel oil. 3# and 4# boilers are used to provide medium-pressure steam, which can not only consume fuel oil, but also fuel gas. image 3 Among them, there are 11 steam turbines (energy-consuming equipment), and steam turbines 1#, 2#, 6#, and 7# are power generation steam turbines, which drive generators to provide electric energy for the system. 3#-5#, 8#-11# are power steam turbines, which are used to drive power equipment. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com