Capacity fixed and loop closed cyclic gas analyzing method and device for surlfur determiner for circular titration

A closed-loop, gas analysis technology, used in measurement devices, analytical materials, chemical analysis using combustion, etc., can solve the problem of high requirements for sensor probe and airflow stability, uneven gas concentration time distribution, and sensitive sensor probes. It can reduce the sensitivity requirements, the gas concentration is uniform, and the production cost can be reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

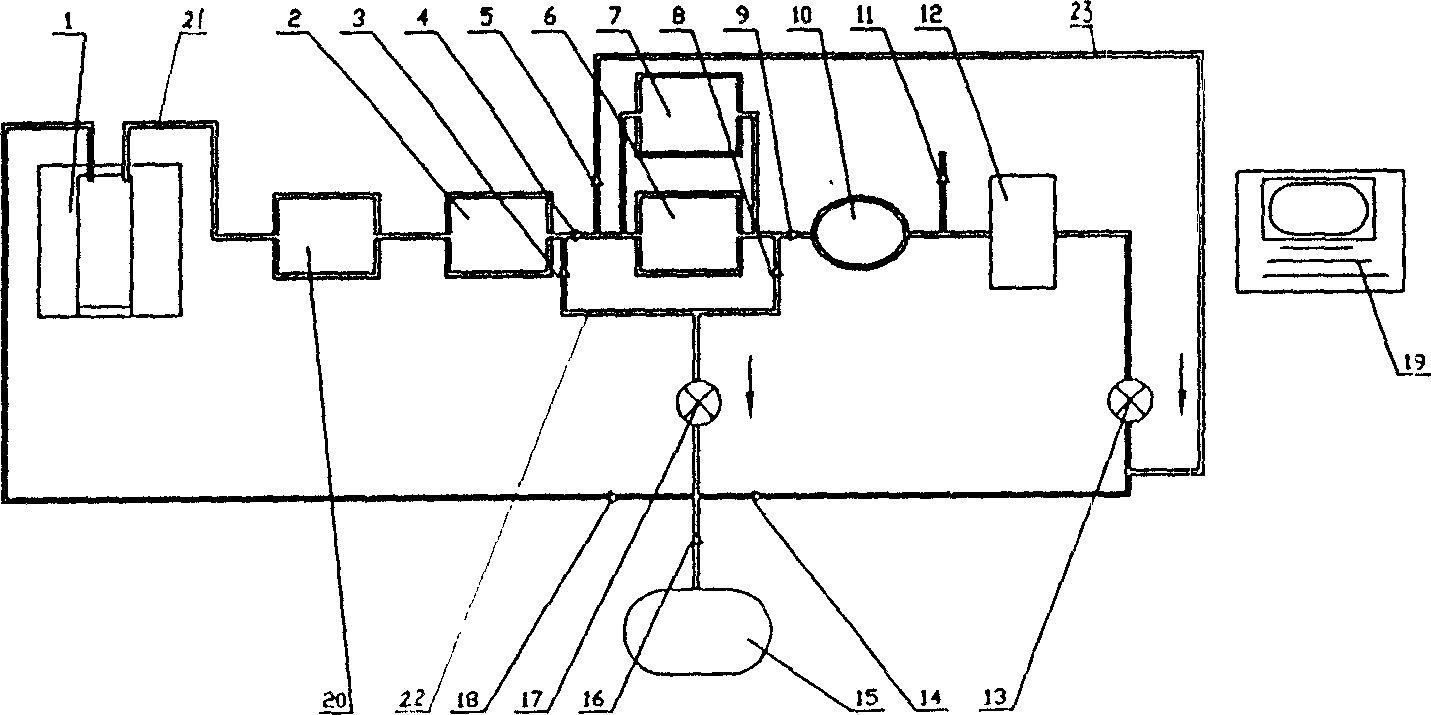

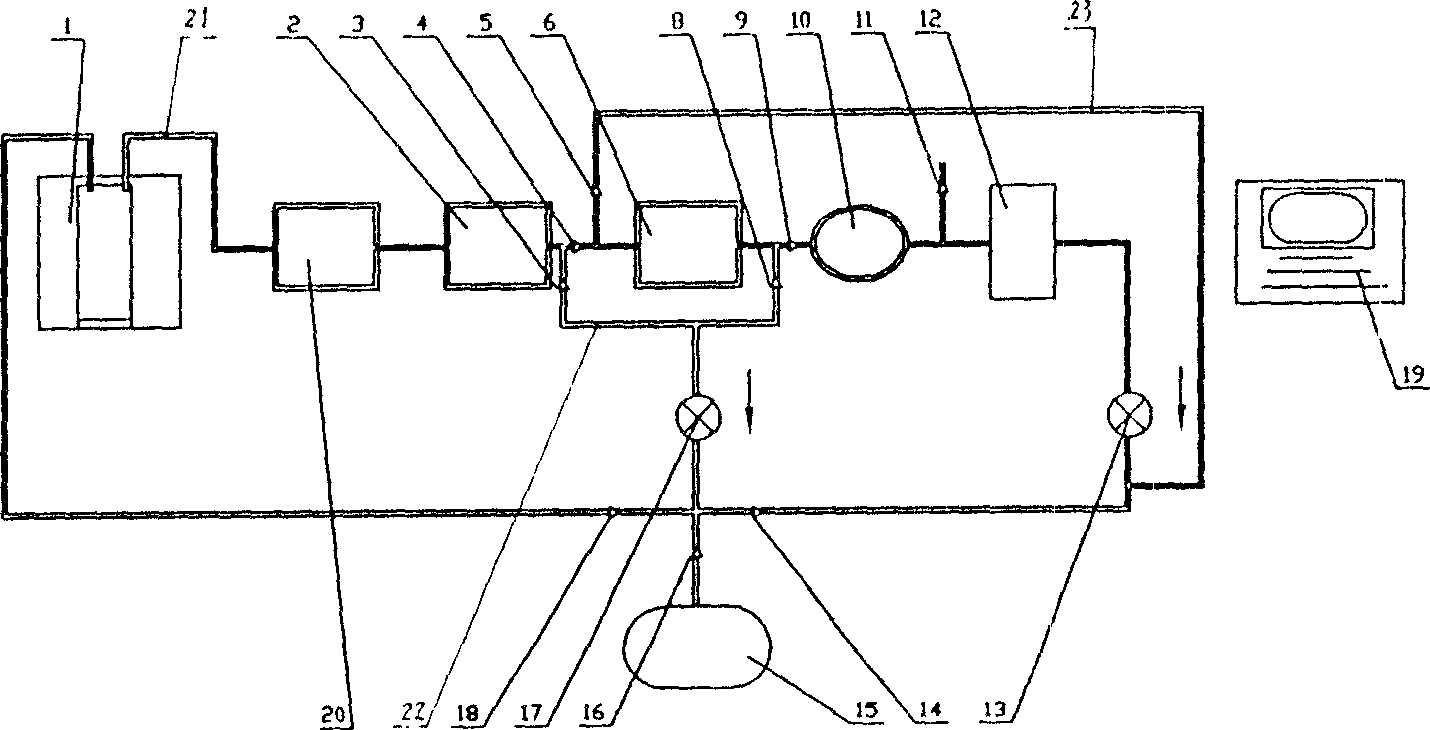

[0017] The applicant has discovered through research that the existing coulometric method uses the measurement method of extracting gas while burning the sample. Since the gas flow uses an open circuit, the gas concentration will be very uneven, which will cause the test to be unstable . The invention solves the problem of uneven gas concentration during the test by making the combusted gas flow in a closed loop, and then by setting the control valve to control the gas direction in the loop, and only extracting less volume of gas during the test That is, at the same time, in order to ensure the measurement of gases with higher sulfur content, another branch pipeline is set in the circulation loop to return the gas that is too late to titrate to the gas chamber and then perform titration, which can further ensure the accuracy of the test Therefore, the technical effect to be achieved by the present invention is realized.

[0018] The specific method of the present invention is as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com