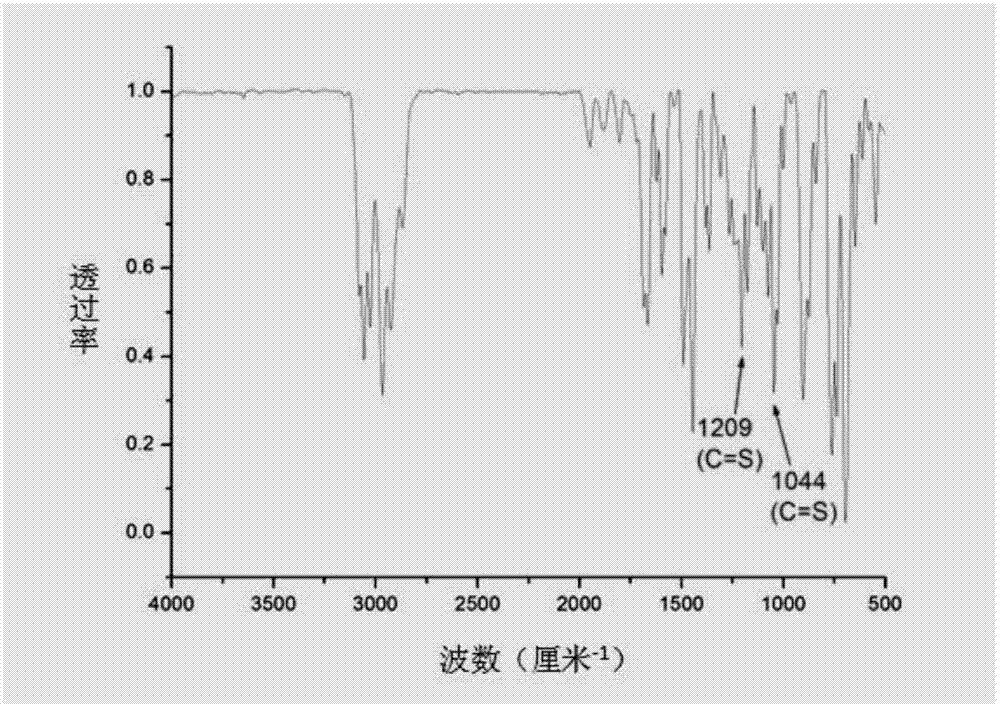

Preparation method for monodisperse functionalized polymer microsphere with surface chain transfer activity

A technology of chain transfer and functionalization, which is applied in the field of preparation of monodisperse surface chain transfer active functionalized polymer microspheres, can solve problems such as poor spheroid formation, achieve stable surface functional groups, high chain transfer activity, and synthetic conditions easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

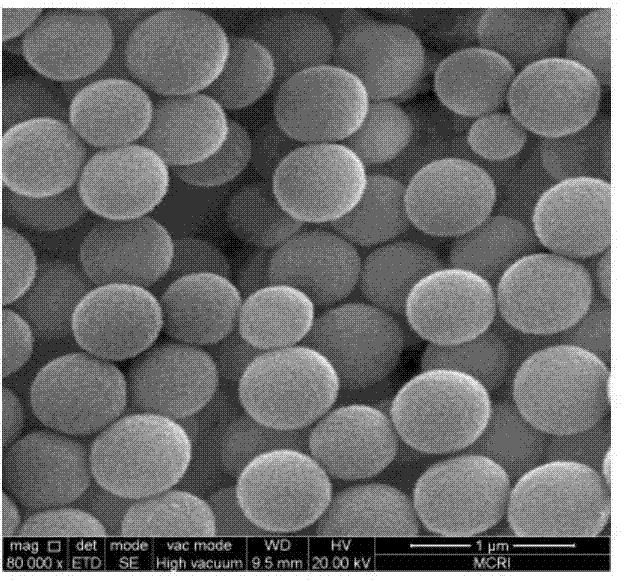

Embodiment 1

[0029] Example 1: 2mL of DVB, 0.0430g of AIBN, 0.1557g of cumyl dithiobenzoate (CDB) and 100mL of acetonitrile were added to a 250mL single-necked flask in sequence, and 0.5g of zeolite was added until the mixture was fully dissolved. Access to N 2 Remove oxygen for 30 minutes, then install a Soxhlet extractor with a volume of 60mL and a condenser tube (the volume of the distilled solvent and the remaining solution = 3:2), seal the system and feed condensed water. Put the reaction device in a 1000mL electric heating mantle and start heating, the power is set to 150W, the reaction temperature is 82°C, and the reaction is carried out for 6h. After the reaction, the pink suspension was passed through a 60mL G6 sand core funnel, filtered under reduced pressure (vacuum degree 0.08), and the obtained polymer was washed with methanol 5 times (rinsing with 20mL methanol each time), and then in Dry to constant weight in a vacuum oven at 50°C, and the obtained microspheres are named M-...

Embodiment 2

[0032] Example 2: Add 4mL of DVB, 1mL of MAA, 0.1002g of AIBN, 0.3514g of cumyl dithiobenzoate (CDB) and 240mL of acetonitrile into a 500mL single-necked flask in sequence, add 0.5g of zeolite, and wait The mixture was fully dissolved. Access to N 2Remove oxygen for 30 minutes, then install a Soxhlet extractor with a volume of 60mL and a condenser tube (the volume of the distilled solvent and the remaining solution = 1:4), seal the system and pass in condensed water. Put the reaction device in a 1000mL electric heating mantle and start heating, the power is set to 150W, the reaction temperature is 82°C, and the reaction is carried out for 6h. After the reaction, the pink suspension was passed through a 60mL G6 sand core funnel, filtered under reduced pressure (vacuum degree 0.08), and the obtained polymer was washed with methanol 5 times (rinsing with 20mL methanol each time), and then in Dry in a vacuum oven at 50°C until constant weight, and the obtained microspheres are n...

Embodiment 3

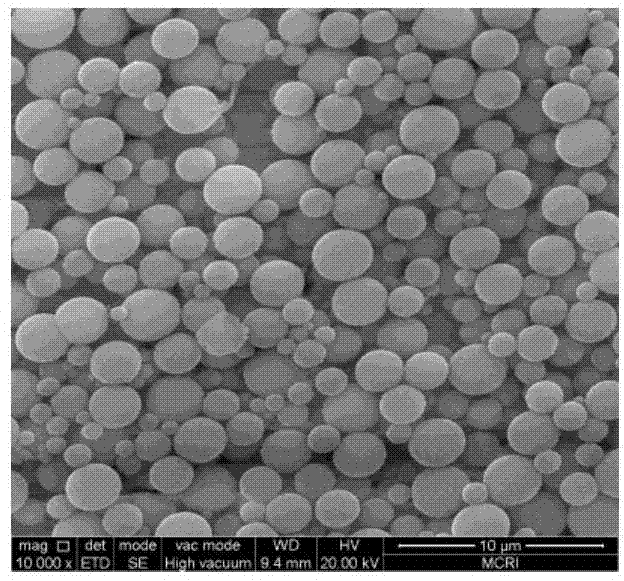

[0034] Example 3: 2mL of DVB, 0.0442g of AIBN, 0.1549g of cumyl dithiobenzoate (CDB) and 100mL of acetonitrile were added to a 250mL single-necked flask in sequence, and 0.5g of zeolite was added until the mixture was fully dissolved. Access to N 2 Remove oxygen for 15 minutes, then install a Soxhlet extractor with a volume of 60mL and a condenser tube, and inject condensed water after the system is sealed. Put the reaction device in a 1000mL electric heating mantle and start heating, the power is set to 300W, the reaction temperature is 82°C, and the reaction is carried out for 6h. After the reaction, the pink suspension was passed through a 60mL G6 sand core funnel, filtered under reduced pressure (vacuum degree 0.08), and the obtained polymer was washed with methanol 5 times (rinsing with 20mL methanol each time), and then in Dry to constant weight in a vacuum oven at 50°C, and the obtained microspheres are named M-3.

[0035] The scanning electron microscope picture of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com