Supported bimetallic reforming catalyst and preparation method and application thereof

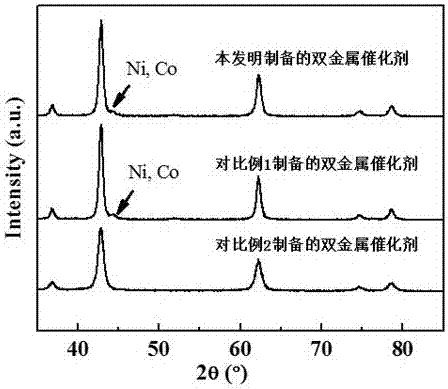

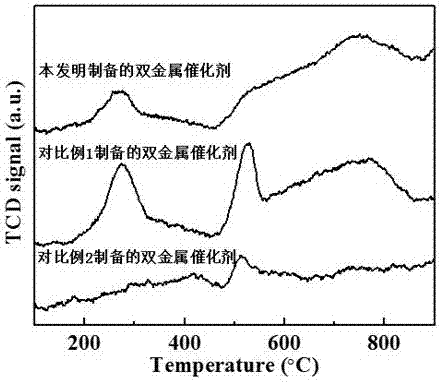

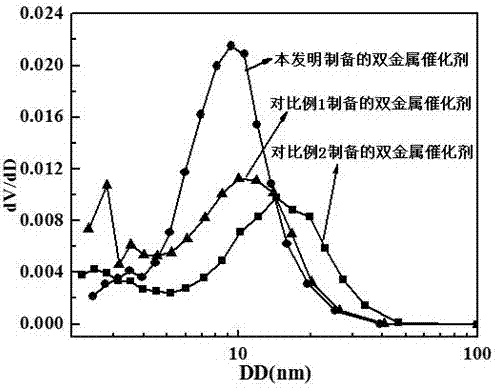

A reforming catalyst and bimetallic technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Microstructure, difference in anti-coking ability, different catalyst reactivity and selectivity, etc., to achieve high catalytic activity and anti-coking performance, convenient operation, and easy control of synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Adopt the inventive method to prepare a kind of highly active bimetallic methane carbon dioxide reforming catalyst, comprise the steps:

[0035] (1) Dissolve 0.7946g nickel nitrate and 0.1976g cobalt nitrate in 20mL deionized water to make mixed solution A;

[0036] (2) Weigh 0.8194g urea and dissolve it in 60mL deionized water to obtain solution B;

[0037] (3) Add 2g of magnesium oxide carrier to solution A, stir at 80°C for 2 hours to obtain solution C;

[0038] (4) Add solution B to solution C, adjust the addition rate (8mL / min) to ensure that the pH of the mixed system is around 10, and keep the mixed system at 80°C for 8 hours after the addition is complete;

[0039] (5) Suction filter, wash, dry at 100° C. for 6 hours, and calcinate at 800° C. for 10 hours to obtain a supported bimetallic methane carbon dioxide reforming catalyst.

Embodiment 2

[0041] Adopt the inventive method to prepare a kind of highly active bimetallic methane carbon dioxide reforming catalyst, comprise the steps:

[0042] (1) Dissolve 0.2435g nickel chloride and 0.1615g cobalt chloride in 10mL deionized water to make mixed solution A;

[0043] (2) Weigh 0.1023g urea and dissolve it in 10mL deionized water to obtain solution B;

[0044] (3) Add 1 g of alumina carrier to solution A, stir at 30°C for 2 hours to obtain solution C;

[0045] (4) Add solution B to solution C, adjust the addition rate (5mL / min) to ensure that the pH of the mixed system is around 8, and keep the mixed system at 60°C for 15 hours after the addition is complete;

[0046] (5) Suction filter, wash, dry at 80° C. for 12 hours, and calcinate at 600° C. for 16 hours to obtain a supported bimetallic methane carbon dioxide reforming catalyst.

Embodiment 3

[0048] Adopt the inventive method to prepare a kind of highly active bimetallic methane carbon dioxide reforming catalyst, comprise the steps:

[0049] (1) Dissolve 0.4966g nickel nitrate and 0.0.4770g cobalt sulfate in 30mL deionized water to make mixed solution A;

[0050] (2) Weigh 0.4086g sodium hydroxide and dissolve it in 60mL deionized water to obtain solution B;

[0051] (3) Add 2 g of magnesium oxide carrier to solution A, stir at 50°C for 2 hours to obtain solution C;

[0052] (4) Add solution B to solution C, adjust the addition rate (12mL / min) to ensure that the pH of the mixed system is around 12, and keep the mixed system at 100°C for 8 hours after the addition is complete;

[0053] (5) Suction filter, wash, dry at 150° C. for 5 h, and calcinate at 600° C. for 10 h to obtain a supported bimetallic methane carbon dioxide reforming catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com