Method for synthesizing zeolite on cordierite carrier

A technology for synthesizing zeolite and cordierite, which is applied in the direction of separation methods, chemical instruments and methods, molecular sieves and alkali exchange compounds, etc., can solve the problems of harsh synthesis conditions, unfavorable zeolite synthesis, and uneven growth of zeolite on the carrier surface, etc., to achieve The effect of low processing cost, easy control of synthesis conditions, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

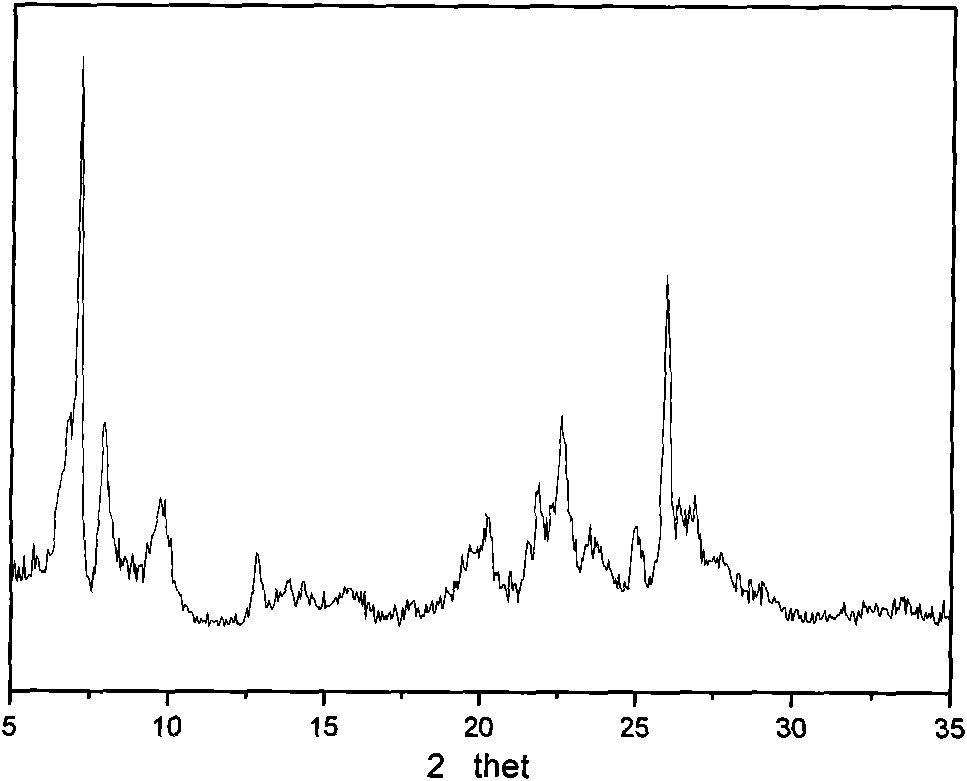

[0014] The cordierite with a volume of 5ml was treated in a 50% oxalic acid solution with a mass concentration at 80℃ for 6 hours, washed with deionized water to neutrality, and then put into a 10% mass concentration sodium hydroxide solution at 80℃ Lower treatment for 5 hours, wash and dry at 120℃, then put it into MCM-22 synthetic solution, the molar ratio of each component in MCM-22 synthetic solution is SiO 2 : Al 2 O 3 : Na 2 O: HMI: H 2 O=1:0.33:0.1:0.35:20, the silicon source used is silica gel, and the aluminum source is sodium metaaluminate. Crystallized at 140°C for 72 hours. Take out the treated cordierite, dry it at 120°C for 12 hours, roast it at 540°C for 10 hours, and ultrasonically clean it for 20 minutes. The XRD characterization results are shown in figure 1 , Indicating that MCM-22 zeolite was synthesized on the carrier, and the electron microscope results (see figure 2 ) Shows that the cordierite surface is firmly loaded with a layer of MCM-22 zeolite, which c...

Embodiment 2

[0016] The carrier treatment process and the support synthesis process were the same as in Example 1, using citric acid with a concentration of 60%, the treatment temperature was 70°C, and the time was 10 hours. The silicon source used was ethyl orthosilicate, XRD results showed that the supported zeolite was MCM-22 zeolite, and the loading amount was 40%.

Embodiment 3

[0018] The carrier treatment process and the supported synthesis process are the same as in Example 1. The molar ratio of the components of the MCM-22 synthesis solution is SiO 2 : Al 2 O 3 : Na 2 O:HMI:H2O=1:0.25:0.12:0.35:20, XRD results show that the loaded zeolite is MCM-22 and some mordenite impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com