A kind of method for preparing nickel cobalt lithium manganese oxide

A technology of nickel-cobalt lithium manganate and lithium cobalt manganate is applied to the preparation of positive electrode materials for lithium ion batteries and the field of preparation of nickel-cobalt lithium manganate, which can solve the problems of irregular crystal morphology, low cost and uneven particle distribution. , to achieve the effect of high morphology and structure consistency, consistent morphology and structure, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

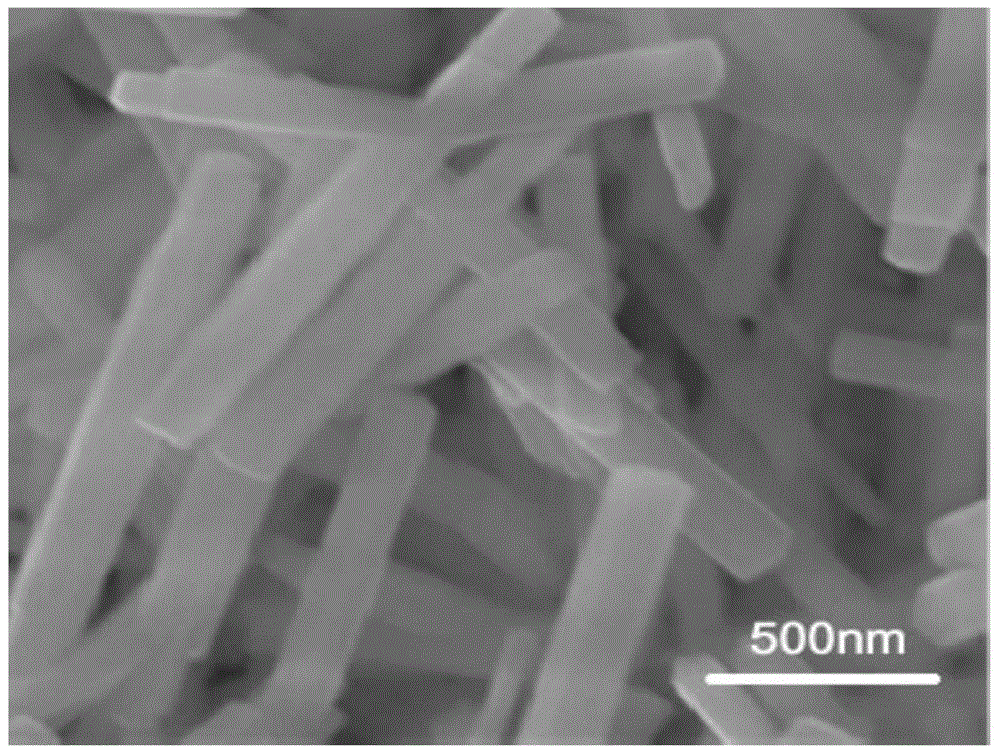

Image

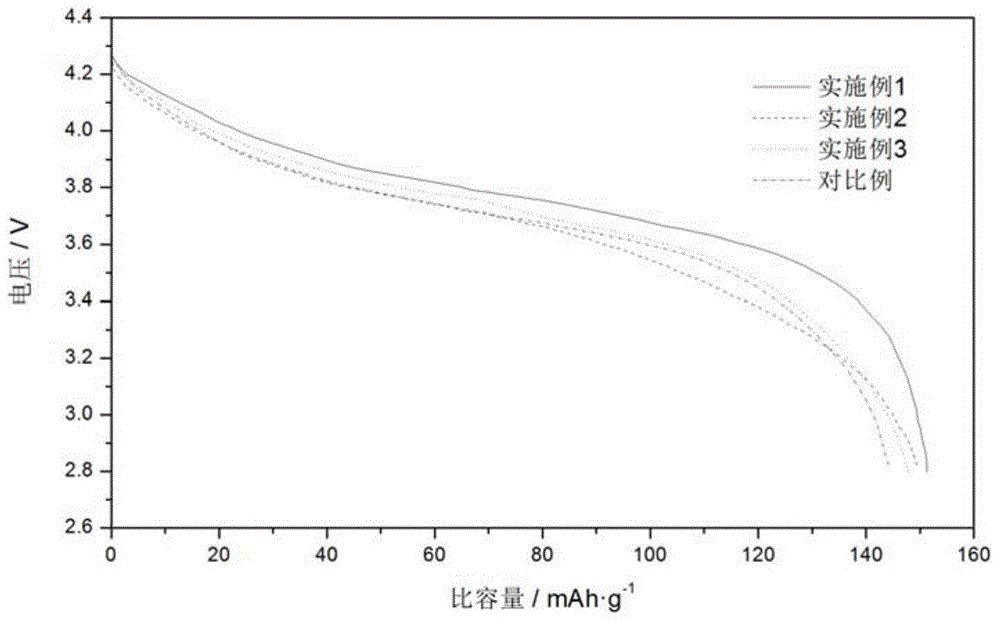

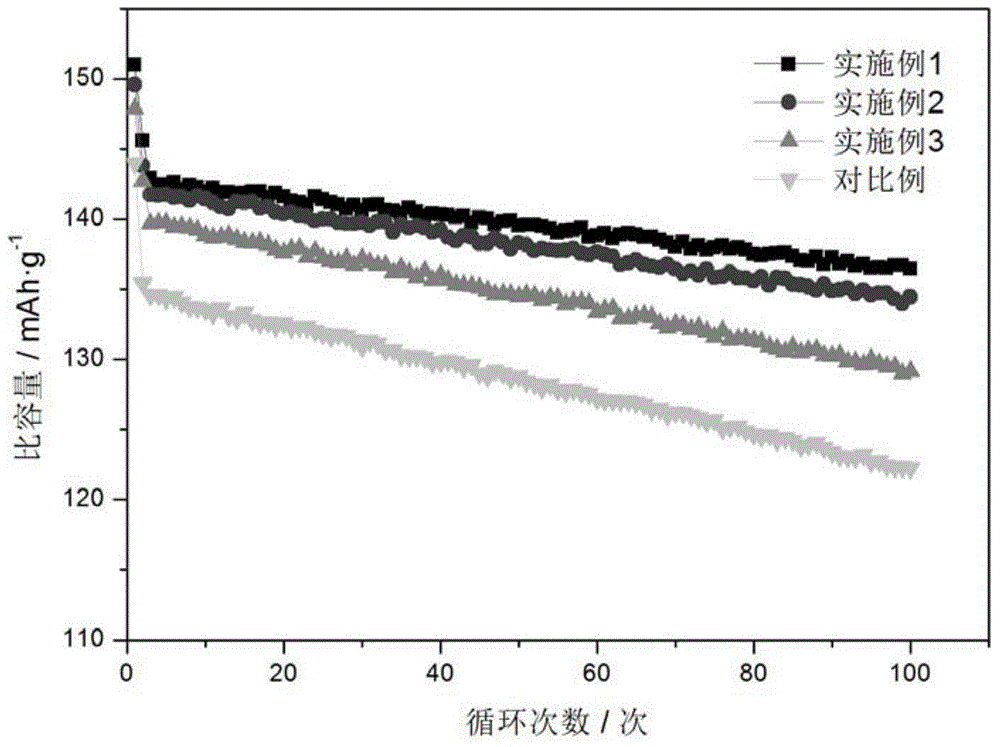

Examples

Embodiment 1

[0039] (1) Polish the aluminum foil with a thickness of 0.5mm with 50-mesh sandpaper to make the surface of the aluminum foil smooth, which is conducive to the formation of an orderly porous template, soak it in acetone for 30min, wash it with deionized water, and heat it to 100°C under nitrogen , keep 1h.

[0040] (2) Use aluminum foil as anode, graphite rod as cathode, calomel electrode as reference electrode, and 0.1mol / L acetic acid solution as electrolyte. Electrochemically polish for 3 minutes at room temperature and 4V voltage. After taking it out, use deionized water Wash and dry for later use.

[0041] (3) Using polished aluminum foil as anode, graphite rod as cathode, calomel electrode as reference electrode, 0.1mol / L sulfuric acid as electrolyte, ice-water bath (about 0°C), 20V voltage, electrochemical oxidation for 1h.

[0042] (4) After taking out, cleaning and drying the primary oxidized aluminum foil, soak it in the mixed solution of acetic acid and phosphoric ...

Embodiment 2

[0051] (1) Polish the aluminum foil with a thickness of 0.5mm with 50-mesh sandpaper, soak it in alcohol for 30min, wash it with deionized water, heat it to 150°C under nitrogen, and keep it for 1.5h.

[0052] (2) Aluminum foil is used as anode, graphite rod is used as cathode, calomel electrode is used as reference electrode, 0.15mol / L acetic acid is used as electrolyte, at room temperature, 5V voltage, electrochemical polishing for 4min, after taking it out, wash it with deionized water Dry and set aside.

[0053] (3) Using polished aluminum foil as anode, graphite rod as cathode, calomel electrode as reference electrode, 0.2mol / L tartaric acid as electrolyte, ice water bath, 25V voltage, electrochemical oxidation for 1.5h.

[0054] (4) Take out the primary oxidized aluminum foil, wash it, and dry it, then soak it in a solution of 0.75mol / L acetic acid and 0.15mol / L phosphoric acid, the volume of the solution is 5.5mL, and soak at 45°C for 45min.

[0055] (5) Using the prim...

Embodiment 3

[0062] (1) Polish the aluminum foil with a thickness of 0.5mm with 50-mesh sandpaper, soak it in acetone for 30min, wash it with deionized water, heat it to 200°C under nitrogen, and keep it for 2h.

[0063] (2) Use aluminum foil as anode, graphite rod as cathode, calomel electrode as reference electrode, and 0.2mol / L acetic acid as electrolyte. Electrochemically polish for 5 minutes at room temperature and voltage of 6V. After taking it out, wash it with deionized water Dry and set aside.

[0064] (3) Using polished aluminum foil as anode, graphite rod as cathode, calomel electrode as reference electrode, 0.3mol / L phosphoric acid as electrolyte, ice-water bath (about 0°C), 30V voltage, electrochemical oxidation for 2h.

[0065] (4) Take out, wash and dry the primary oxidized aluminum foil, soak it in a solution consisting of 1 mol / L acetic acid and 0.2 mol / L phosphoric acid, the volume of the solution is 6 mL, and soak at 50°C for 1 hour.

[0066] (5) Use the primary oxidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com