Cordierite matrix catalyst used for preparing synthesis gas by reforming methane and carbon dioxide and preparation method thereof

A carbon dioxide and cordierite technology, applied in the field of catalyst and its preparation, can solve the problems of affecting the service life of the catalyst, poor matching of the catalyst coating, affecting the bonding strength of the interface, etc., achieving low cost, good anti-carbon performance and stability , the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A cordierite-based bimetallic catalyst with a solid solution mass fraction of 10% was prepared by in-situ synthesis:

[0020] Raw material: cobalt nitrate Co(NO 3 ) 2 ·6H 2 O; aluminum nitrate Al(NO 3 ) 3 9H 2 O; nickel nitrate Ni(NO 3 ) 2 ·6H 2 O; magnesium nitrate Mg(NO 3 ) 2 ·6H 2 O; nitric acid HNO 3 ; Ammonia NH 3 ·H 2 O;

[0021] Substrate: Honeycomb cordierite with a pore density of 200 pores / square inch and a wall thickness of about 0.3mm;

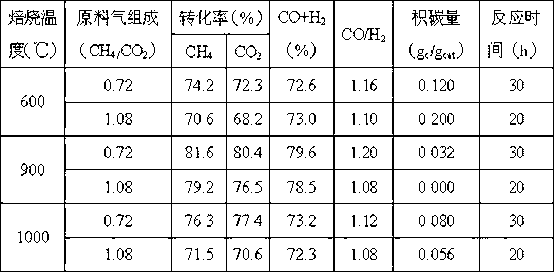

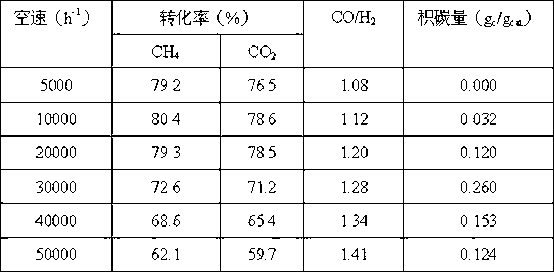

[0022] Honeycomb cordierite with a volume of 5.2ml was treated in a nitric acid solution with a mass concentration of 14% at 30°C for 4 hours, washed with deionized water, and dried at 120°C for 12 hours. Simultaneously take by weighing the cobalt nitrate, nickel nitrate, magnesium nitrate, aluminum nitrate that quality is 2.2073g, 1.9380g, 3.4176g, 5.0g by the mol ratio of 1:1:2:2 and be dissolved in 150ml deionized water and be mixed with solution, put 3.4ml of ammonia water with a mass fraction of 15% was ...

Embodiment 2

[0024] A cordierite-based bimetallic catalyst with a solid solution mass fraction of 3% was prepared by in situ synthesis:

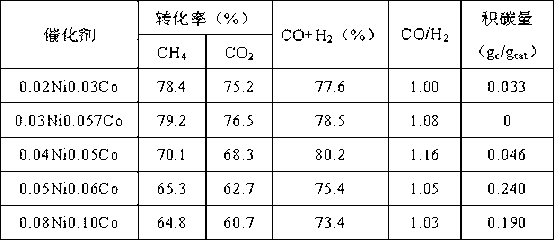

[0025] Catalyst preparation: with reference to the method in Example 1, change the molar ratio of raw materials, and take by weighing 2.6488g, 1.1628g, 9.2275g, 7.5g of cobalt nitrate, nickel nitrate, and magnesium nitrate in a molar ratio of 1:2:5:9 , aluminum nitrate to prepare a cordierite-based bimetallic catalyst loaded with a solid solution with a mass fraction of 3%, and the contents of Ni, Co, Mg, and Al are 2%, 3%, 40% and 55% of the solid solution mass, respectively. The evaluation results of its catalytic performance for methane carbon dioxide reforming to synthesis gas are listed in Table 2.

Embodiment 3

[0027] Loading capacity and firmness of cordierite-based bimetallic catalysts prepared by in situ synthesis:

[0028] The substrate treatment process and loading synthesis process are the same as in Example 1, and the ratio of cobalt nitrate, nickel nitrate, magnesium nitrate, and aluminum nitrate is changed to obtain a cordierite substrate bimetallic catalyst. It is 2.9-10%, indicating that the coating is firmly bonded to the cordierite matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com