Method for synthesizing MWW mole cular sieve

A synthesis method and molecular sieve technology, which are applied in molecular sieve compounds, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve problems such as difficulty in controlling the composition of raw materials, increasing the synthesis cost of molecular sieves, and large differences in composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] After adding 0.435g of alumina to 72.7g of water under stirring, 3.1g of HMI was added, the pH value was adjusted to about 12 with NaOH, and silica gel (99%) was added to form a reaction mixture. The composition of each component was as follows:

[0039] SiO 2 / Al 2 o 3 =20,H 2 O / SiO 2 =45, R / SiO 2 =0.35, reaction mixture pH=12

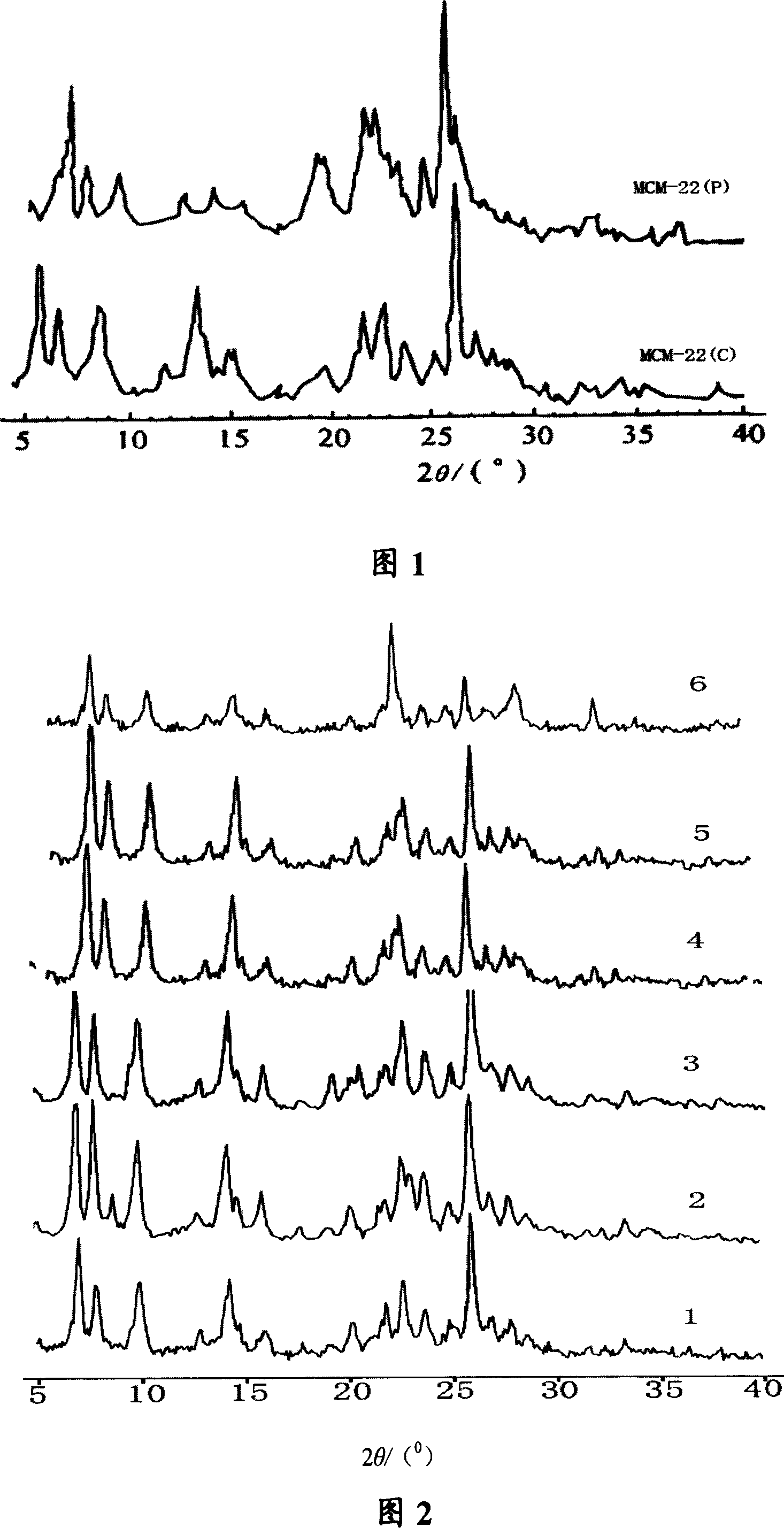

[0040] Here R stands for HMI. Put the reaction mixture in a reaction kettle, keep the temperature at 110°C for 8 hours, then raise the temperature to 150°C for 10 days; the reactant is filtered and washed, and dried at 120°C. The obtained sample is marked as MCM-22(P ); MCM-22(P) was calcined at 550°C, and the obtained sample was designated as MCM-22(C). The X-ray diffraction patterns (XRD) of MCM-22(P) and MCM-22(C) are shown in FIG. 1 .

Embodiment 2

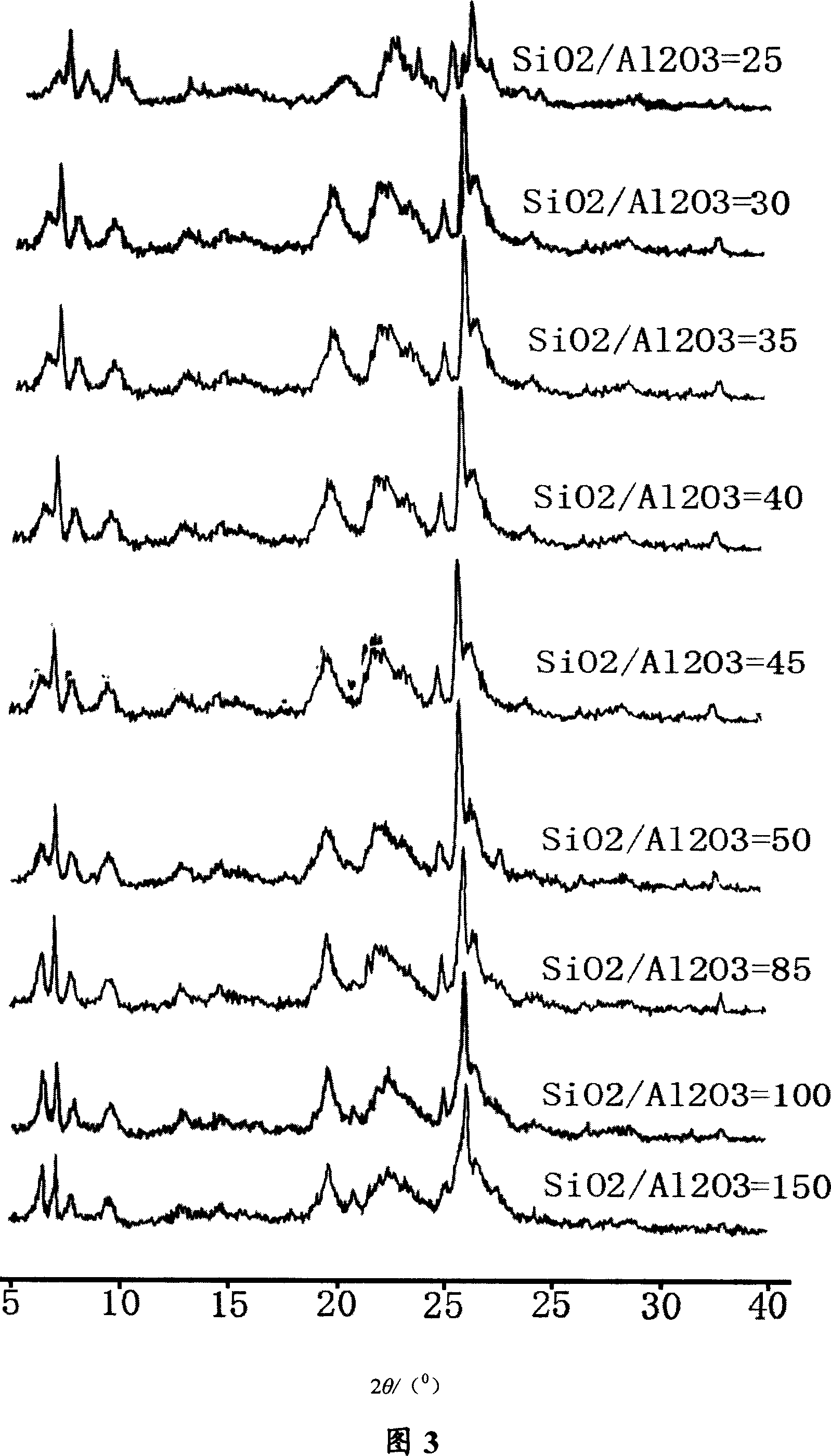

[0042] According to the steps of Example 1, adjust the pH value of the system with barium hydroxide, prepare the mixture composed in Table 1, keep the temperature at 119°C for 5 days, and keep the temperature at 155°C for 8 days. After filtering and washing the reactant, dry it at 120°C Dry, baked at 550 ° C, the XRD pattern of each sample is shown in Figure 2.

[0043] The mixture composition of table 1 embodiment 2

[0044] No.

Embodiment 3

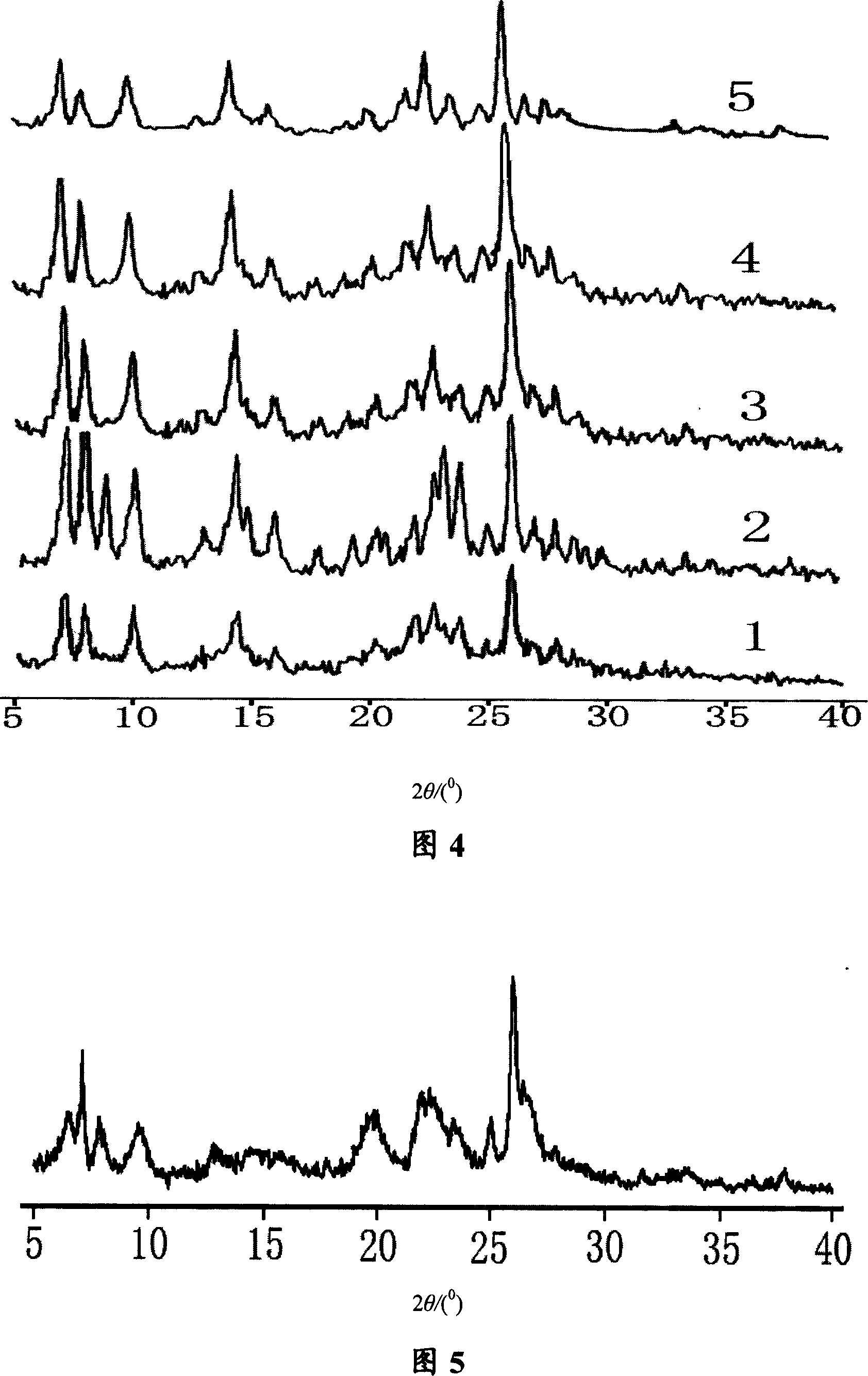

[0046] According to the method of embodiment 1, prepared SiO 2 / Al 2 o 3 =25, 30, 35, 40, 45, 50, 85, 100, 150 MCM-22 molecular sieves, the XRD pattern of the product obtained is shown in Figure 3. The results showed that the synthesized samples were all MCM-22 molecular sieves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com