High performance molecular sieve membrane of silicon by using ceramics of silicon dioxide as carrier, and preparation method

A silicon molecular sieve and silicon dioxide technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reducing the hydrophobicity of siliconalite molecular sieve membrane, and achieve easy control of synthesis conditions, simple operation, and application. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

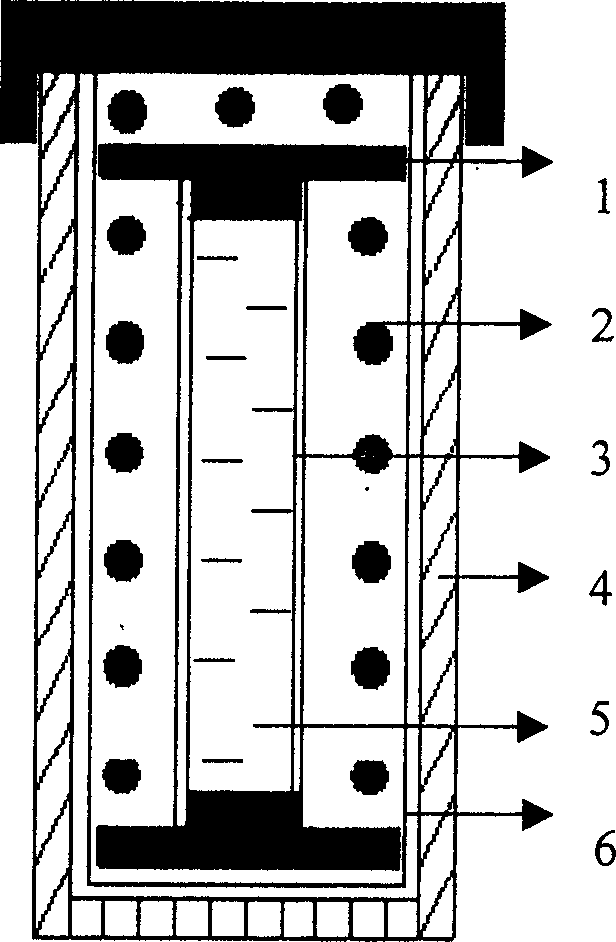

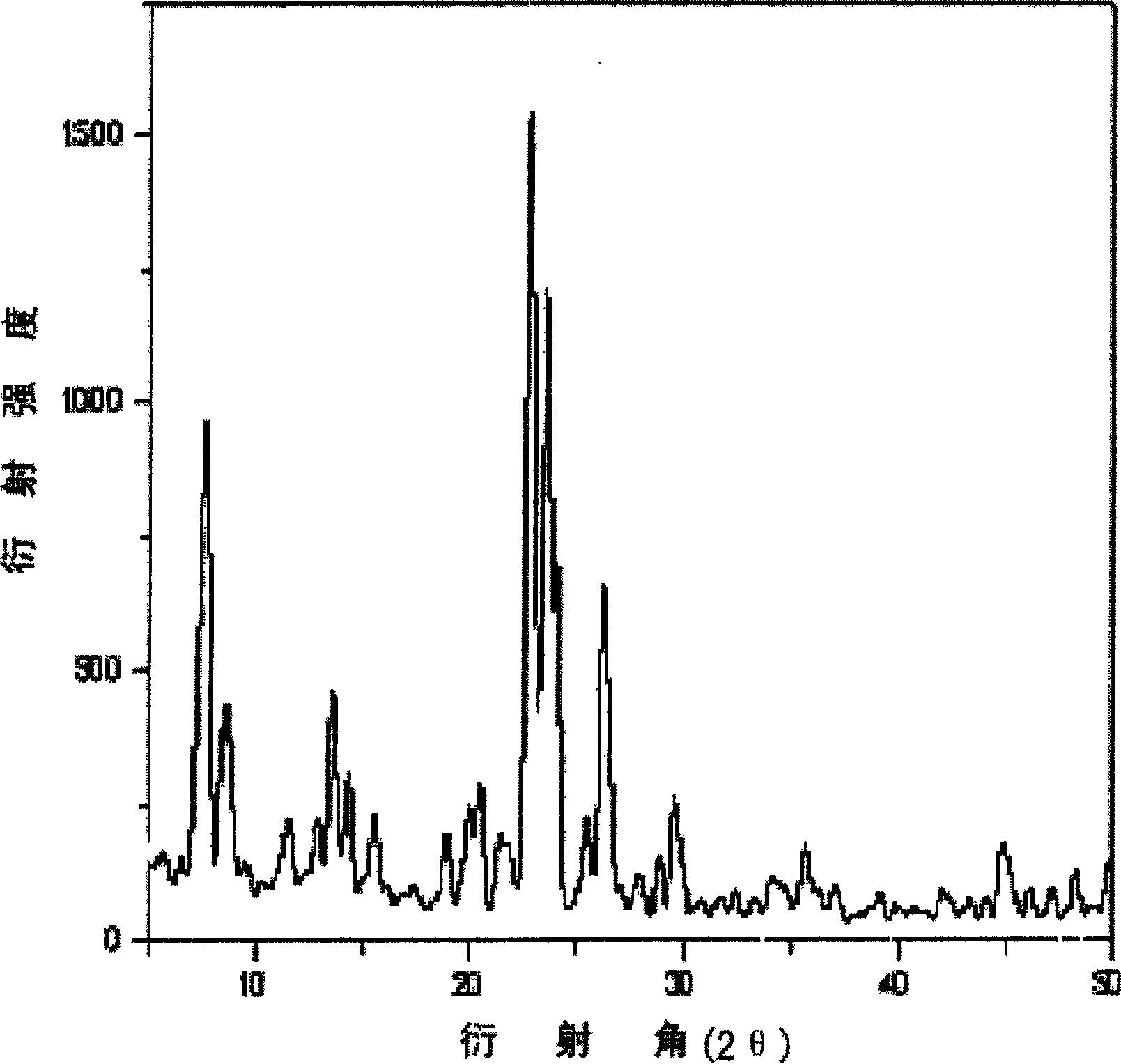

[0037] The synthesis of embodiment 1 tubular silicalite molecular sieve membrane

[0038] The porous silica ceramic carrier used in the experiment has a ceramic tube with an outer diameter of 11 mm, an inner diameter of 7 mm, a length of 90 mm, an average pore diameter of 0.26 μm, and a porosity of about 45%. The flaky silica carrier used for XRD characterization has a diameter of 25 mm, a thickness of 2 mm, and the same average pore diameter and porosity as the tubular carrier. After the carrier is smoothed by 1000 mesh fine sandpaper, it is cleaned by ultrasonic waves in distilled water, and then treated at high temperature for later use. The dried ceramic tubes and sheet-like supports are directly used for synthesis without the need for pre-coated seeds.

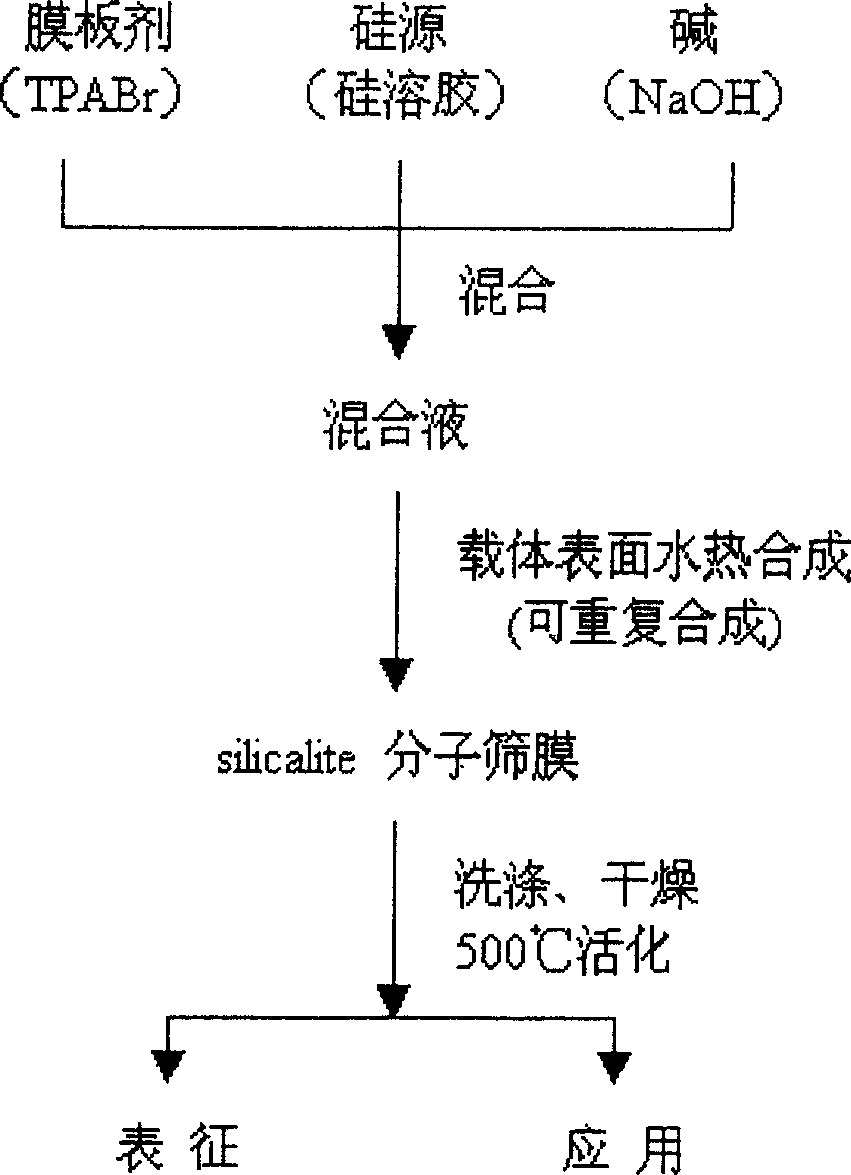

[0039] The schematic diagram and schematic diagram of the preparation are as follows figure 1 and figure 2 shown.

[0040] Weigh a certain amount of NaOH and dissolve it in distilled water, stir to dissolve, add tetr...

Embodiment 2

[0043] The synthesis of embodiment 2 tubular silicalite molecular sieve membranes

[0044] The same operation as in Example 1 was carried out, except that the aging temperature used was different, and the aging condition before hydrothermal synthesis was aging at 75° C. for 12 hours. From the scanning electron microscope photo, it can be seen that a uniform and dense molecular sieve film is formed on the surface of the carrier, and the molecular sieve crystal is a typical MFI crystal shape (such as Figure 6 , 7 shown). See S-3 and S4 in Table 2 for the results of molecular sieve membrane pervaporation experiments on the two tubular supports.

[0045] membrane tube

Embodiment 3

[0046] The synthesis of embodiment 3 tubular silicalite molecular sieve membranes

[0047] Weigh a certain amount of NaOH and dissolve it in distilled water, stir to dissolve, add tetrapropylammonium bromide (TPABr), stir and dissolve for a period of time, add a certain amount of silica sol to the above mixed solution, and stir thoroughly. The composition (molar ratio) of each component in the final solution is: 1TPABr: 0.25Na 2 O: 10SiO 2 : 600H 2 o

[0048] Seal one end of the unseeded porous silica ceramic tube with a polytetrafluoroethylene bracket, fill it with a mixed solution of glycerin and water, seal the other end with a polytetrafluoroethylene bracket, and place it vertically on the Pour the reaction solution into a reaction kettle lined with a polytetrafluoroethylene liner, age it in an oven at 75°C for 8 hours before synthesis, then in-situ hydrothermally synthesize it at 180°C for 24 hours, cool it down to room temperature naturally, and wash it with distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com