Li-CO2 battery anode catalyst material and preparation method thereof, battery anode material and battery

A battery positive electrode and catalyst technology, applied in the field of electrochemistry, can solve the problems affecting the electrochemical performance of the battery, agglomeration, shedding, etc., and achieve the effect of improving the electrocatalytic performance of the positive electrode of Li-CO2 batteries, simple and easy operation of the process, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a Li-CO 2 A method for preparing a positive electrode catalyst material for a battery, comprising the following steps:

[0032] a. Pour 15mg of graphene, 50mg of ruthenium trichloride hydrate, 50mg of copper acetate, 200mg of polyvinylpyrrolidone (PVP), and 20ml of ethylene glycol into a four-necked flask to prepare a precursor solution. The precursor solution is in a four-necked flask The filling amount is 20%~50%, and the four-neck flask is ultrasonicated at 50Hz for 0.5h.

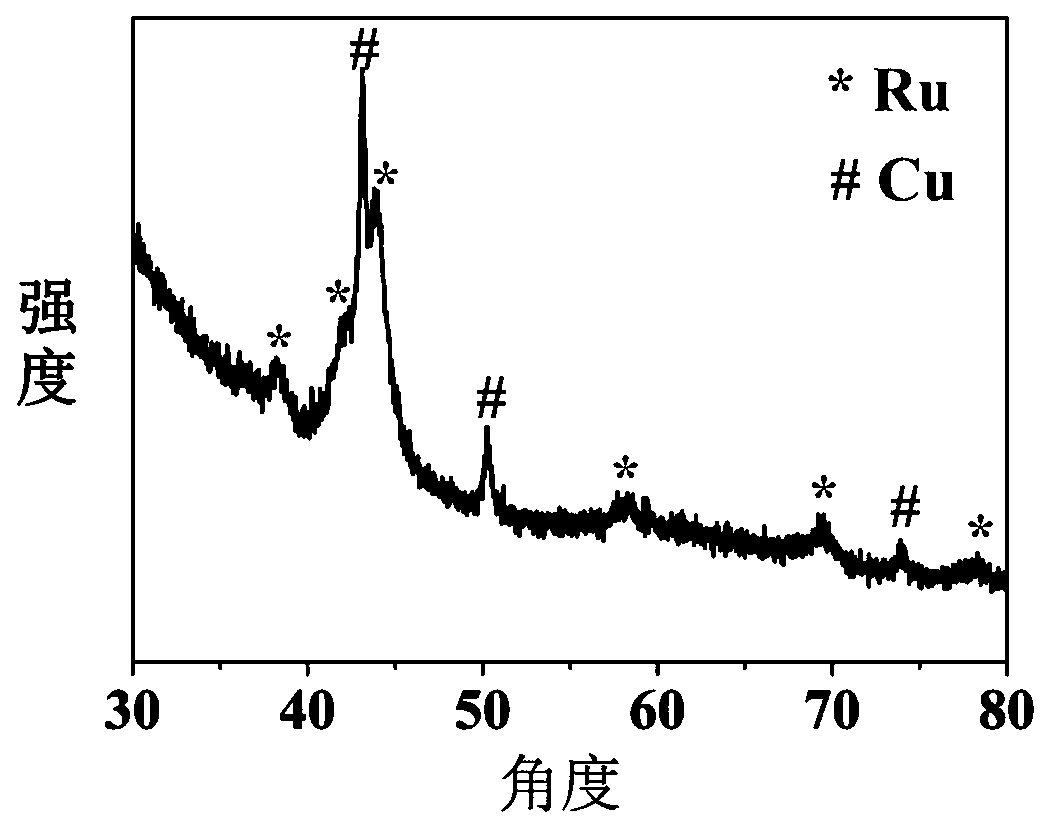

[0033] b. In an argon environment, connect the four-necked flask to a condensing device, stir evenly in an oil bath at 180°C for two minutes, then add 0.5ml of benzaldehyde, continue stirring for 1 hour, and cool; centrifuge at 9500 rpm, wash with ethanol six times, Centrifuge for 8 minutes each time; place in a vacuum oven at 80 o C dried overnight; calcined at 600°C for 8 hours in a tube furnace fed with argon-hydrogen mixed gas, 90% argon and 10% hydrogen in the argon-hydrogen mixed gas to ob...

Embodiment 2

[0038] a Li-CO 2 Battery positive electrode material, by weight percentage, by 90% above-mentioned Li-CO 2 The battery cathode catalyst material and 10% binder (PVDF) composition.

[0039] Contains the above Li-CO 2 Li-CO as battery cathode material 2 The positive electrode sheet of the battery, the preparation steps are as follows:

[0040] 1) Dissolve 4.5mg of positive electrode catalyst material and 0.5mg of polyvinylidene fluoride (PVDF) in 0.2ml of nitrogen-methylpyrrolidone (NMP), stir on a magnetic stirrer for 1 hour, and mix well to obtain a liquid mixture.

[0041] 2) Spread the above liquid mixture on the carbon sheet (model TGP-H-060, 12mm in diameter, purchased from Shanghai Hesen Electric Co., Ltd.), the film surface should be as flat as possible, at 80 o After drying in a C oven for 12 hours, Li-CO 2 Battery positive electrode sheet (the amount of NMP depends on the amount of liquid mixture on the carbon sheet and the number of positive electrode sheets prod...

Embodiment 3

[0043] With the Li-CO that embodiment 2 obtains 2 Battery positive pole piece assembled columnar Li-CO 2 For batteries, it was carried out in an inert glove box filled with high-purity Ar, humidity and O 2 The content is all controlled below 1ppm, and the steps are as follows:

[0044] 1) Send the black positive electrode sheet, negative electrode sheet, battery shell, separator, current collector, electrolyte, disposable straw, plastic tweezers, and sealed bag into the glove box;

[0045] 2) The self-made electrode disc is used as the positive electrode, the lithium sheet is used as the negative electrode, the diaphragm is made of porous polypropylene diaphragm, and the electrolyte is 1M LITFSI / TEGDME (the diaphragm should be soaked in the electrolyte for a period of time);

[0046] 3) First drop a drop of electrolyte in the bottom case of the battery, then add lithium sheet, diaphragm, and black positive electrode sheet in sequence (place the side with the material facing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com