Recycling and reuse technology for preparing triphenylchloromethane

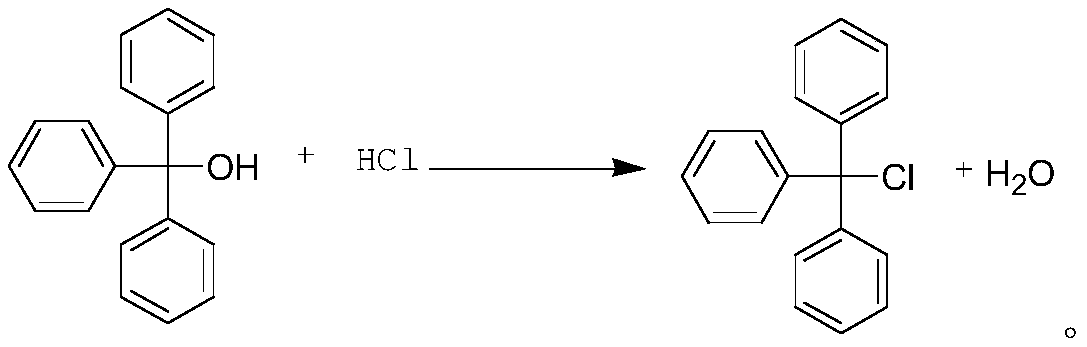

A technology of triphenylchloromethane and cyclic application, which is applied in the preparation of halogenated hydrocarbons, the production of bulk chemicals, organic chemistry, etc., can solve the problem that the purity of recycled materials cannot be well guaranteed, tar-like substances are easily generated, and the production site is affected. environment and other issues, to achieve the effect of convenient source of raw materials, controllable impurities and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Synthesis of Triphenylchloromethane

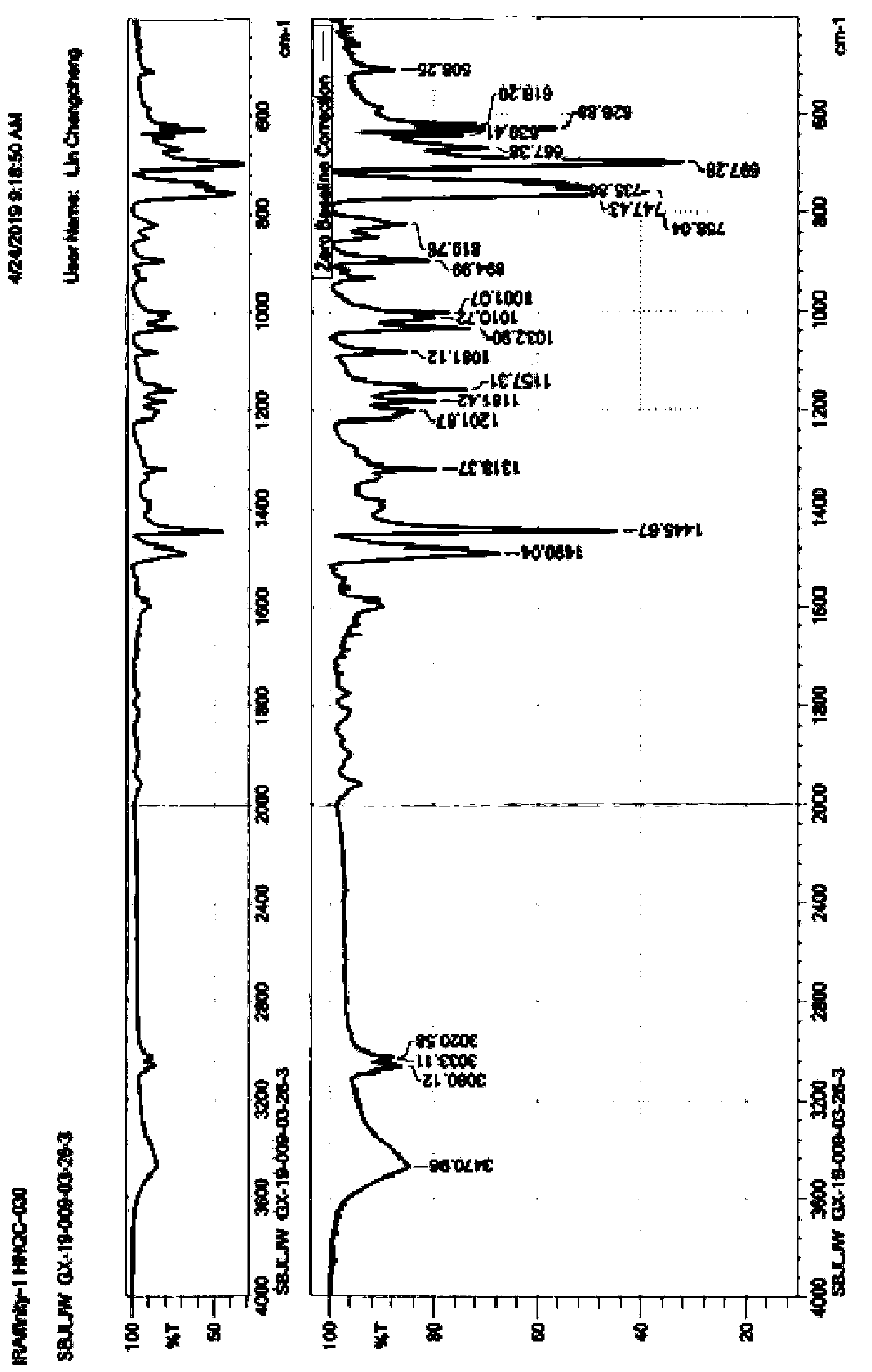

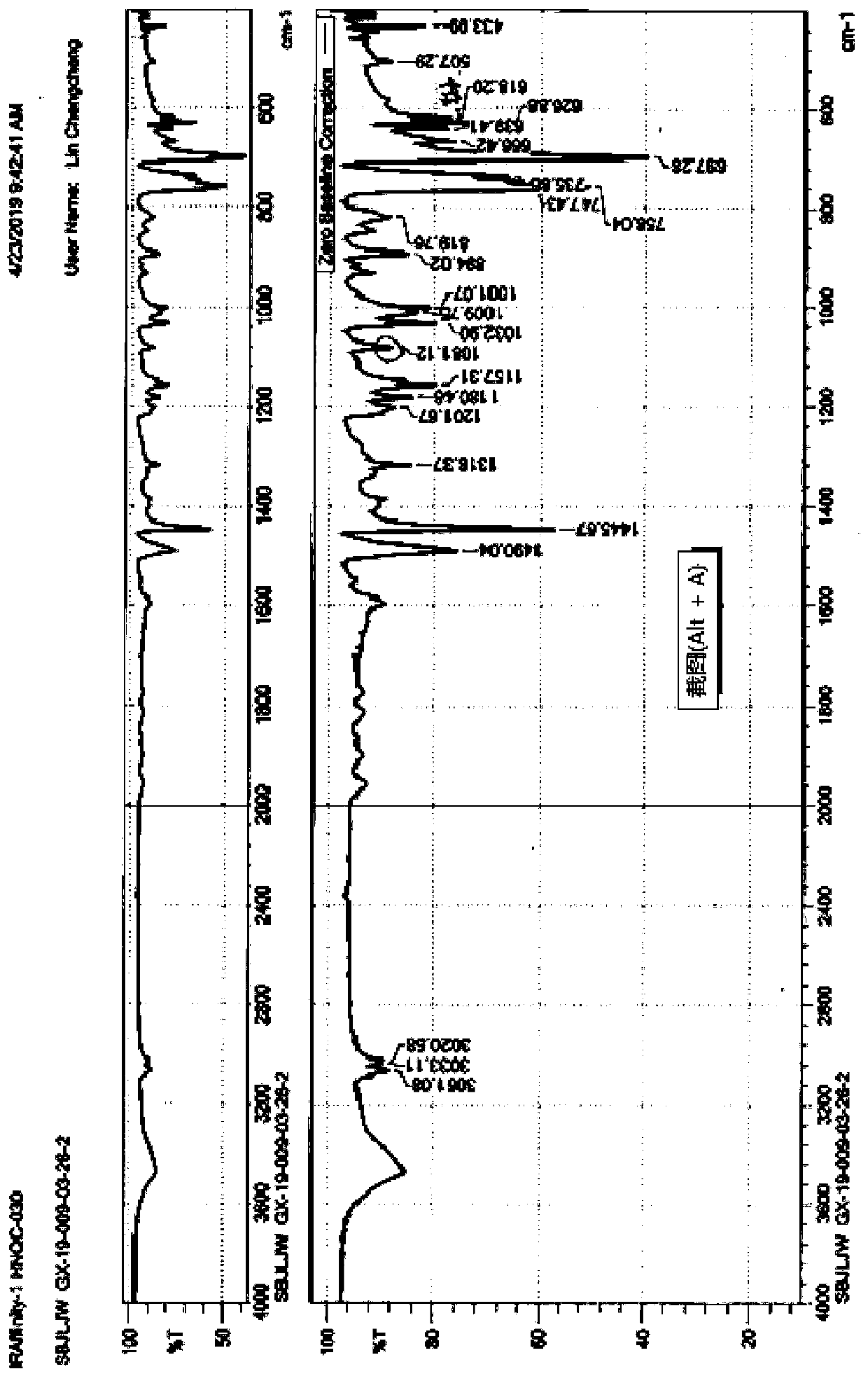

[0046] Recover 500mL of triphenylmethanol toluene solution (containing 50g of triphenylmethanol with a purity of 98% or more), add 50mL of concentrated hydrochloric acid, stir at 25°C for 5h, stand for 0.5h to separate the water layer, control the vacuum and concentration temperature figure 2 , Attached with standard product figure 1 Consistent.

example 2

[0048] Synthesis of Triphenylchloromethane

[0049] Recover 500mL of triphenylmethanol toluene solution (containing 50g of triphenylmethanol, with a purity of 98% or more), add 50mL of concentrated hydrochloric acid, 5g of calcium chloride, stir for 5h at 25°C, stand for 0.5h to separate the water layer, control the vacuum and Concentrate temperature <30℃, concentrate toluene to dryness to obtain a solid containing triphenylchloromethane, raise the temperature to 60℃, continue drying for 5h, weigh 51.4g of triphenylchloromethane, yield: 96.0%, content : 99.3%.

example 3

[0051] Synthesis of Triphenylchloromethane

[0052] Recover 500mL of triphenylmethanol methyl isobutyl ketone solution (containing 50g of triphenylmethanol, purity above 98%), add 50mL of hydrochloric acid, 5g of calcium chloride, stir at 25°C for 5h, stand for 0.5h to separate the water layer, Control the degree of vacuum and the concentration temperature <30℃, concentrate the methyl isobutyl ketone to dryness to obtain a solid containing triphenylchloromethane, raise the temperature to 60℃, continue drying for 6h, weigh to obtain triphenylchloromethane 51.4 g, yield: 96.0%, content: 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com