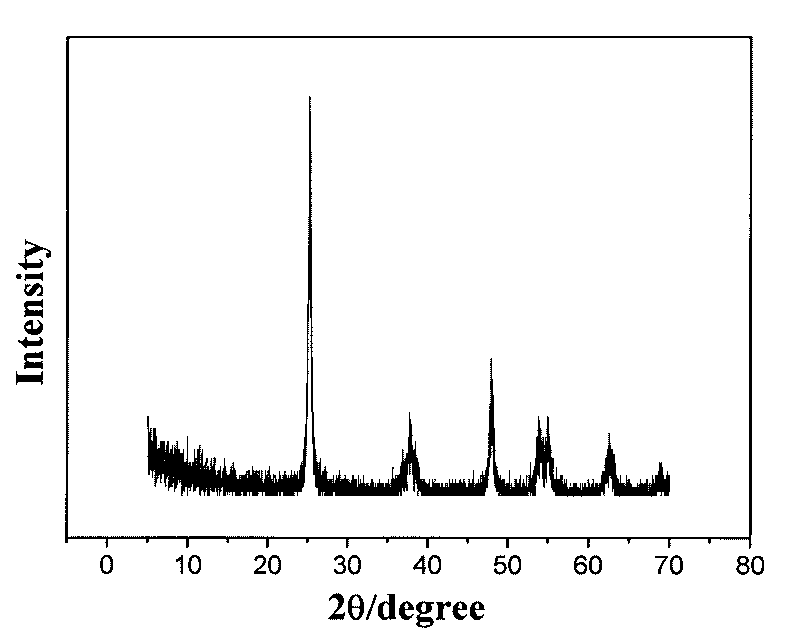

Method for preparing TiO2/Al2O3 composite film

A technology for the preparation of composite membranes and additives, applied in chemical instruments and methods, catalyst activation/preparation, membrane technology, etc., can solve the problems of difficult to obtain membranes and porosity of membranes, so as to improve the utilization rate and increase the Good selectivity and permeate flux, chemical and physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] Mix 3.40g of tetrabutyl titanate and 0.46g of absolute ethanol evenly; under stirring, successively add 198ml of secondary deionized water and 0.58g of nitric acid with a concentration of 65% into the mixture, and heat up to 80°C for aging 12 hours; cool to room temperature, add 0.20 g lactic acid chitosan (0.1 wt.%) and stir evenly to obtain a translucent sol. Its composition is 1TiO 2 :1100H 2 O:0.60H + :4EtOH.

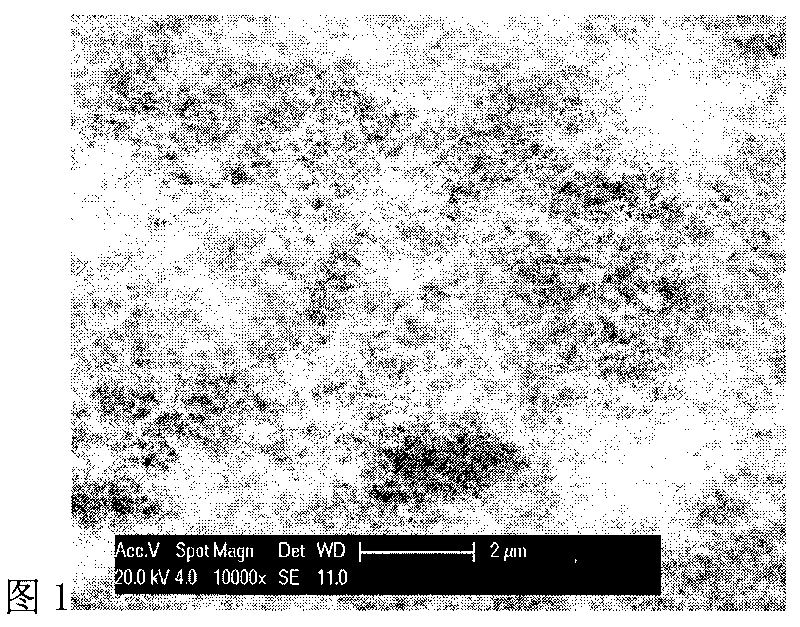

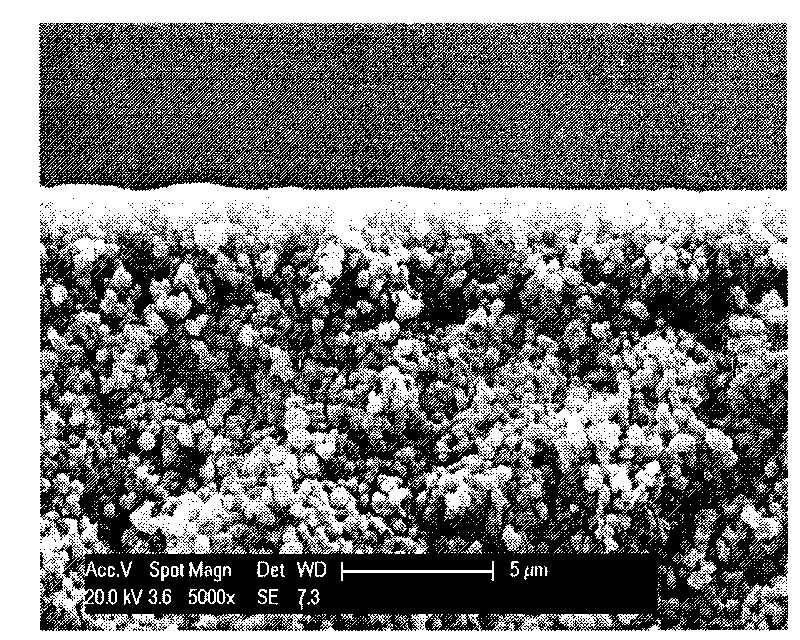

[0021] Dip-pull method is used to coat the film. α-Al 2 o 3 The carrier was immersed in the above sol for 40s, pulled out at a speed of 6 s / cm, and after drying, the temperature was raised to 450°C at a rate of 1°C / min and kept for 3 hours. Repeat the above steps 3 times to obtain TiO 2 / Al 2 o 3 Composite film.

Embodiment approach 2

[0023] Mix 3.40g of tetrabutyl titanate and 1.84g of absolute ethanol evenly; under stirring, successively add 198ml of secondary deionized water and 0.78% of nitric acid with a concentration of 65% into the mixture, and heat up to 80°C for aging for 12 hour; cooled to room temperature, added 1.01g lactic acid chitosan (0.5wt.%) and stirred evenly to obtain a translucent sol. Its composition is 1TiO 2 :1100H 2 O:0.80H + :4EtOH.

[0024] The α-Al 2 o 3 The carrier was immersed in the above sol for 60s, pulled out at a speed of 6s / cm, dried and heated to 450°C at a rate of 2°C / min for 2 hours, and the above steps were repeated 3 times to obtain TiO 2 / Al 2 o 3 Composite film.

Embodiment approach 3

[0026] Mix 2.84g of tetraisopropyl titanate and 1.84g of absolute ethanol evenly; under stirring, successively add 198ml of secondary deionized water and 0.78g of nitric acid with a concentration of 65% into the mixed solution, and heat up to 85 Aging at ℃ for 12 hours; cooling to room temperature, adding 2.01 g of chitosan oligosaccharide (1.0 wt.%) and stirring evenly to obtain a translucent sol. Its composition is 1TiO 2 :1100H 2 O:0.80H + :4EtOH.

[0027] The α-Al 2 o 3 The carrier was immersed in the above sol for 40s, pulled out at a speed of 6s / cm, dried and heated to 400°C at a rate of 1°C / min and kept for 3 hours, repeating the above steps 3 times to obtain TiO 2 / Al 2 o 3 Composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com