Preparation process of hollow silica ball

A technology of silica and hollow spheres, which is applied in the direction of silica and silica, can solve the problems of agglomerated particle size of silica hollow spheres, complex preparation process, and unevenness, so as to shorten the synthesis time and simplify the preparation The effect of gentle steps and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

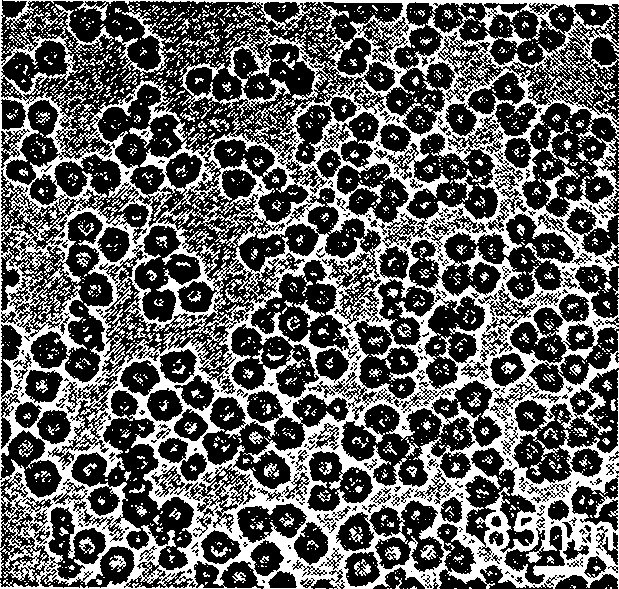

[0018] Example 1: Preparation of hollow silicon dioxide spheres with an inner diameter of 40 nanometers and a wall thickness of 10 to 20 nanometers with polyacrylic acid

[0019] In this embodiment, the polyelectrolyte is polyacrylic acid as an example, the alcohol solvent is ethanol as an example, and the silicon source precursor is tetraethyl orthosilicate as an example; take 0.08 grams of polyacrylic acid and put it in a 50 ml conical flask with a stopper, add 1. 50 ml of 25% ammonia water was slightly stirred until it was completely dissolved, then 30 ml of ethanol was quickly added, and vigorously stirred for 30 minutes, 0.50 ml of 4.4 mol / L tetraethyl orthosilicate was added dropwise at a rate of 0.05 ml / hour, and the stirring was continued after the addition 4 hours. After the reaction, the product obtained was centrifuged and washed at least three times with distilled water and absolute ethanol respectively, so as to remove impurities. Finally, the product was dried i...

Embodiment 2

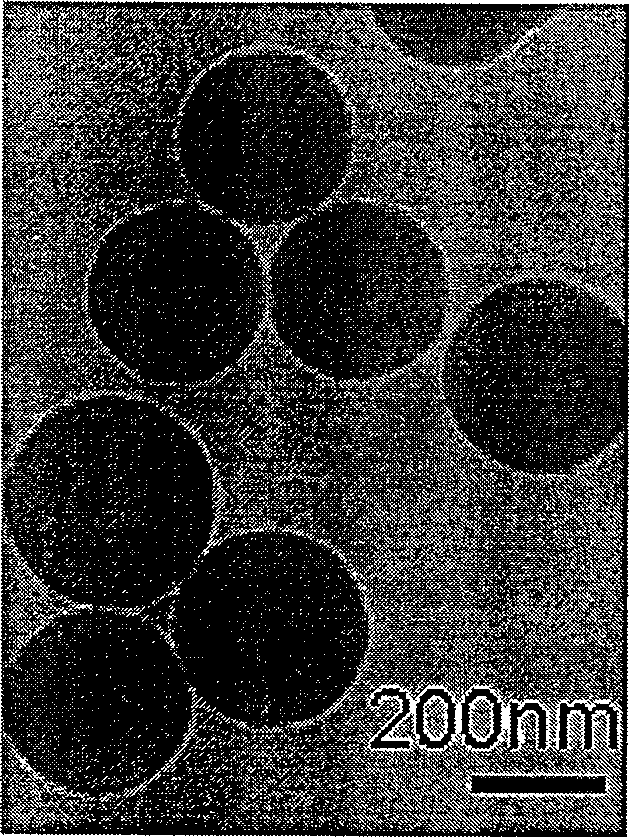

[0031] Example 2: Preparation of hollow silicon dioxide spheres with an inner diameter of 50 to 60 nanometers and a wall thickness of 40 nanometers with sodium polyacrylate

[0032] In this embodiment, the polyelectrolyte is sodium polyacrylate as an example, the alcohol solvent is ethanol as an example, and the silicon source precursor is tetraethyl orthosilicate as an example; take 0.1 g of sodium polyacrylate and place it in a 50 ml stoppered Erlenmeyer flask , add 2.50 ml of 20% ammonia water and stir gently until completely dissolved, quickly add 30 ml of ethanol, stir vigorously for 30 minutes, add 2.00 ml of 2.2 mol / liter tetraethyl orthosilicate dropwise at a rate of 0.2 ml / hour, and the addition is complete Stirring was continued for 10 hours. After the reaction, the product obtained was centrifuged and washed at least three times with distilled water and absolute ethanol respectively, so as to remove impurities. Finally, the product was dried in a vacuum oven at 60°...

Embodiment 3

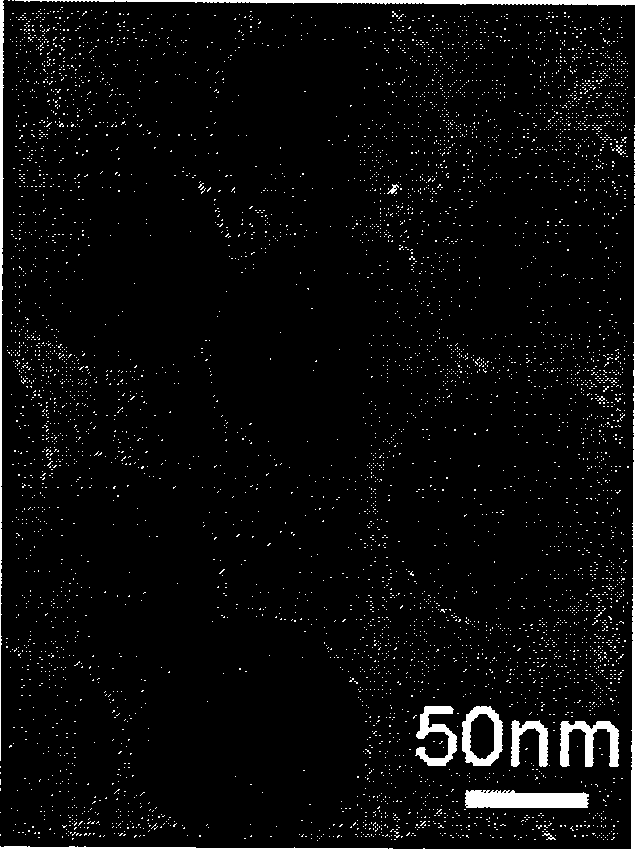

[0040] Example 3: Preparation of hollow silicon dioxide spheres with an inner diameter of 20 nanometers and a wall thickness of 42 nanometers with sodium polymethacrylate

[0041] In this embodiment, the polyelectrolyte takes sodium polymethacrylate as an example, the alcohol solvent takes ethanol and isopropanol as an example, and the silicon source precursor takes tetraethyl orthosilicate as an example; take 0.03 grams of sodium polymethacrylate in Add 2.00 ml of 25% ammonia water to a 50 ml conical flask with a stopper and stir slightly until it is completely dissolved, then quickly add 30 ml of a mixed alcohol solution with a volume ratio of ethanol and isopropanol of 1:1, stir vigorously for 30 minutes, and dissolve 1.80 ml of 4.4 mol / liter tetraethyl orthosilicate was added dropwise at a rate of 0.15 ml / hour, and stirring was continued for 8 hours after the addition was completed. After the reaction, the product obtained was centrifuged and washed at least three times wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com