Preparation method of uniform-grain-size spherical nano cobalt

A technology of nano-cobalt and particle size, applied in the field of preparation of spherical nano-cobalt with uniform particle size, can solve problems such as product agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Prepare uniform particle size spherical nano-cobalt according to the following steps

[0020] (1) Prepare 1L each of 0.01mol / L cobalt sulfate aqueous solution and 0.011mol / L sodium carbonate aqueous solution, and mix the prepared cobalt sulfate aqueous solution and sodium carbonate aqueous solution to obtain basic cobalt carbonate suspension;

[0021] (2) Next, add 0.03 mol of reducing agent sodium hypophosphite to the above suspension, and raise the temperature of the mixture to the reaction temperature of 25°C at 2°C / min under the stirring condition of 250 rpm;

[0022] (3) Then add 0.0001mol trace complexing agent sodium citrate;

[0023] (4) After reacting for 0.5 hours, the product was separated, and the product was washed several times with ethanol and deionized water to obtain a black precipitate, which was dried at 70°C to obtain spherical nano-cobalt with uniform particle size.

Embodiment 2

[0024] Embodiment 2: Prepare spherical nano-cobalt with uniform particle size according to the following steps

[0025] (1) Prepare 1 L of 0.055 mol / L cobalt sulfate aqueous solution and 0.0687 mol / L sodium carbonate aqueous solution respectively, and mix the prepared cobalt sulfate aqueous solution and sodium carbonate aqueous solution evenly to form a basic cobalt carbonate suspension;

[0026] (2) Next, add 0.22mol of reducing agent hydrazine hydrate to the above suspension, and raise the temperature of the mixture to the reaction temperature of 47°C at 3.5°C / min under the stirring condition of 375 rpm;

[0027] (3) Then add 0.00055 mol trace complexing agent sodium tartrate;

[0028] (4) After reacting for 1.25 hours, the product was separated, and the product was washed several times with ethanol and deionized water to obtain a black precipitate, which was dried at 70°C to obtain spherical nano-cobalt with uniform particle size.

Embodiment 3

[0029] Embodiment 3: Prepare uniform particle size spherical nano-cobalt according to the following steps

[0030] (1) Prepare 1L each of 0.1 mol / L cobalt sulfate aqueous solution and 0.15 mol / L sodium carbonate aqueous solution, and mix the prepared cobalt sulfate aqueous solution and sodium carbonate aqueous solution evenly to form a basic cobalt carbonate suspension;

[0031] (2) Next, add 0.5 mol of reducing agent potassium borohydride to the above suspension, and raise the temperature of the mixture to the reaction temperature of 70°C at 5°C / min under the stirring condition of 500 rpm

[0032] (3) Then add 0.001mol trace complexing agent thiourea;

[0033] (4) After reacting for 2 hours, the product was separated, and the product was washed several times with ethanol and deionized water to obtain a black precipitate, which was dried at 70°C to obtain spherical nano-cobalt with uniform particle size.

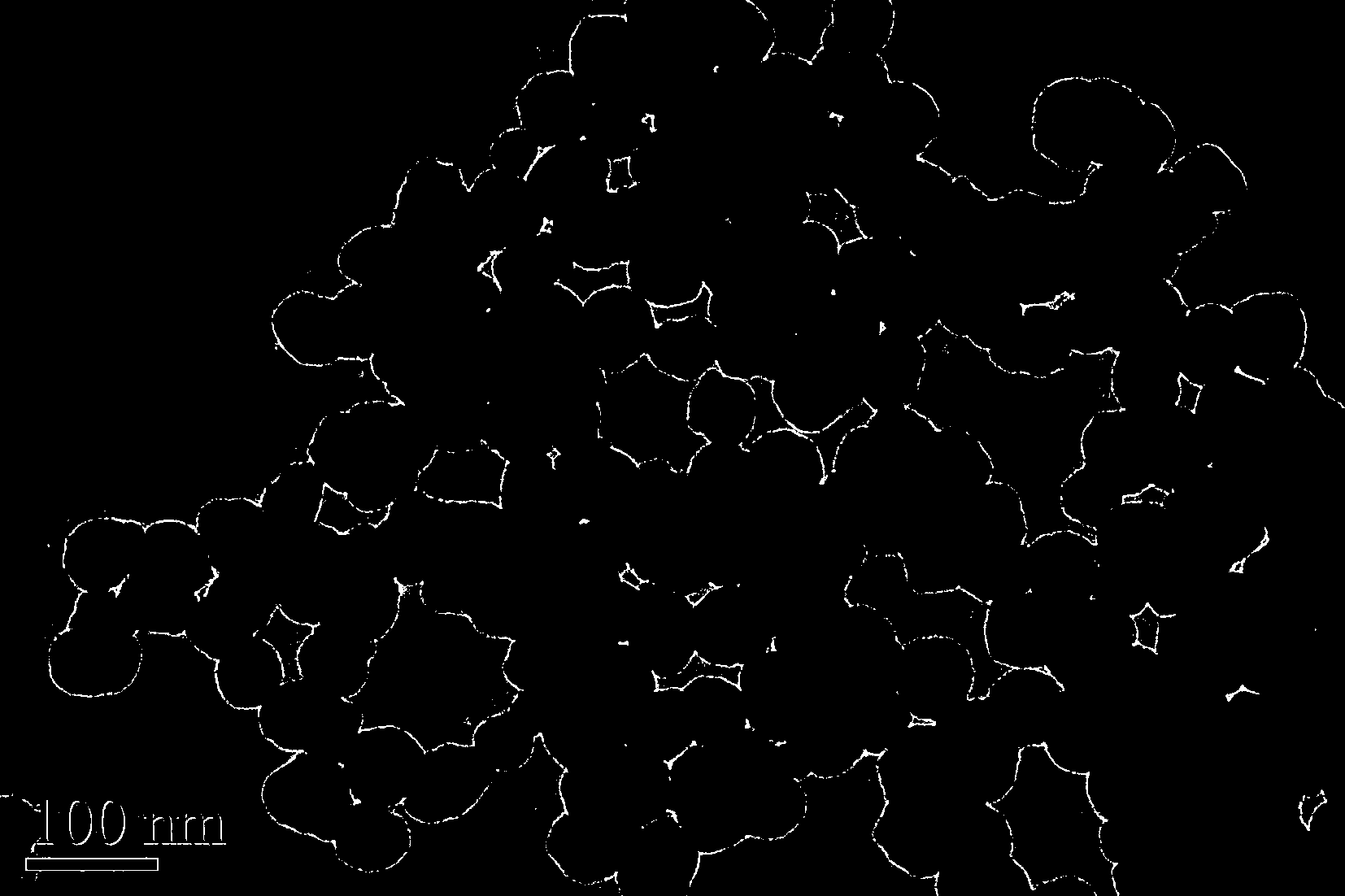

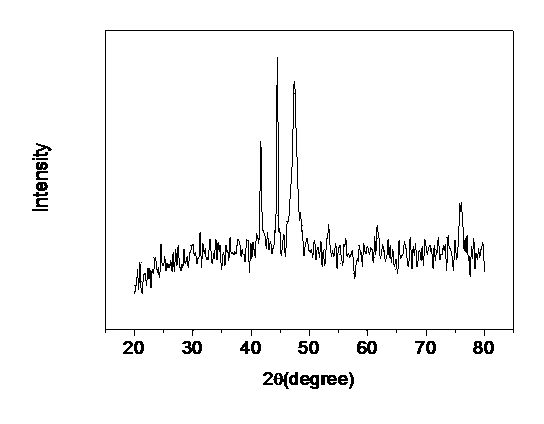

[0034] The transmission electron micrograph of the uniform particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com