Method for forced mixing fabric to reduce sodium content in aluminum hydroxide powder

A technology of aluminum hydroxide and forced mixing, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of high and wide sodium content, accompanied by the formation of large particles, and unsatisfactory application effects. Achieve the effects of reducing sodium content, narrowing the range of particle size distribution, and improving the relative uniformity of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

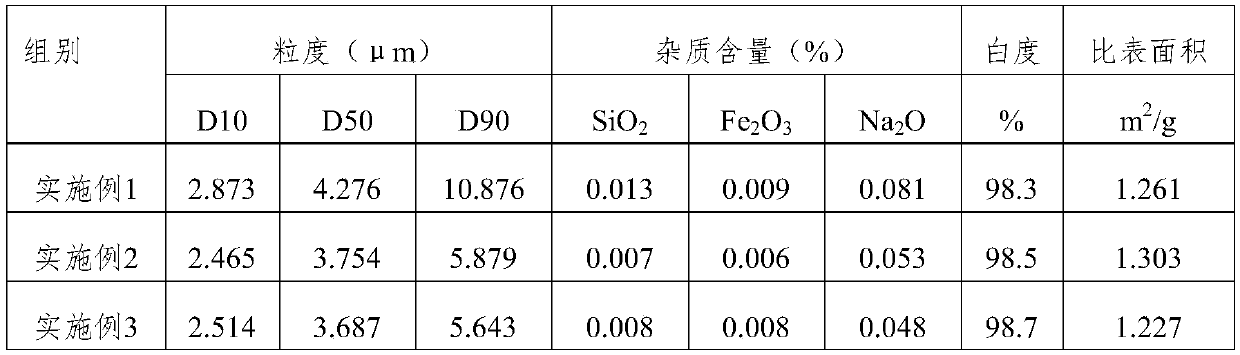

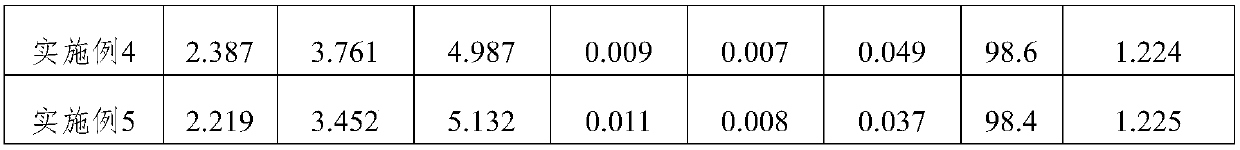

Embodiment 1

[0022] Preparation of seed crystal solution: After mixing aluminum hydroxide and water with 100g of aluminum hydroxide and 100g of water, use a cell mill to grind for 1 hour according to the operation method of the cell mill; adjust the temperature of the seed crystal solution at 100°C, and use an ultrasonic frequency of 60kHz Use immediately after processing for 7 minutes;

[0023] Take aluminum hydroxide, sodium hydroxide, and water at a mass ratio of 1:1:3, prepare a mixed solution at a temperature of 40°C, and add the seed solution to the mixed solution (1kg) by 0.001 times the mass of the mixed solution (1000kg). In the solution, place it in the seed sub-tank at 60°C for decomposition, separate the decomposed slurry from the mother liquor, wash it, and dry it at 40°C for 20 minutes to obtain aluminum hydroxide micropowder.

Embodiment 2

[0025] On the basis of Example 1, after the seed solution is added to the seed sub-trough and mixed with the mixed solution, the mixed material in the seed sub-trough is lifted to the forced mixer at the top of the seed sub-trough by a feeder, and a 2000r / min Stirring speed After mixing for 15 minutes, the solution in the forced mixer is dropped into the seed separation tank by its own gravity to decompose and separate aluminum hydroxide micropowder.

Embodiment 3

[0027] On the basis of Example 1, after the seed solution is added to the seed sub-trough and mixed with the mixed solution, the mixed material in the seed sub-trough is lifted to the forced mixer at the top of the seed sub-trough by a feeder, and a 3000r / min Stirring speed After mixing for 20 minutes, the solution in the forced mixer is dropped into the seed separation tank by its own gravity to decompose and separate aluminum hydroxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com