Preparation method of photoelectrocatalytic oxidation catalyst for treating high-salinity wastewater

An oxidation catalyst, high-salt wastewater technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sewage treatment and other directions, can solve the problems of complex preparation process, expensive raw materials, large pollution, etc., achieve simple preparation steps, High activity and longevity, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 79.2g (NH 4 ) 2 TiF 6 , add 800ml of water to make 0.1mol / L solution A; take 49.6gH 3 BO 3 , add water to make 0.2mol / L solution B. The above two solutions A and B were mixed and diluted to 2 L to obtain a mixed solution.

[0031] 500g porous Al 2 O 3 Carrier (commercially available model TC-01) The diameter of the carrier is 7mm, the number of side openings is 3, and the specific surface area is 10-15m 2 / g, pore volume 0.1-0.3ml / g, water absorption 30-40%, crushing strength 120-150N / cm, pour into the mixture, and deposit in liquid phase at room temperature for 48hrs. After the time is up, take it out, dry it at 110°C for 4 hours, and bake it at 600°C for 3 hours to obtain the finished photocatalyst. The content of catalyst active components is listed in Table 1.

[0032] Catalyst performance evaluation is achieved by the following devices:

[0033] Reactor: fixed-bed photocatalytic reactor, with two electrodes on both sides, the middle part is filled wi...

Embodiment 2

[0040] After the active components were prepared, they were deposited in liquid phase at room temperature for 120 hours, and the rest of the catalyst preparation steps were the same as in Example 1. The content of catalyst active components is listed in Table 1.

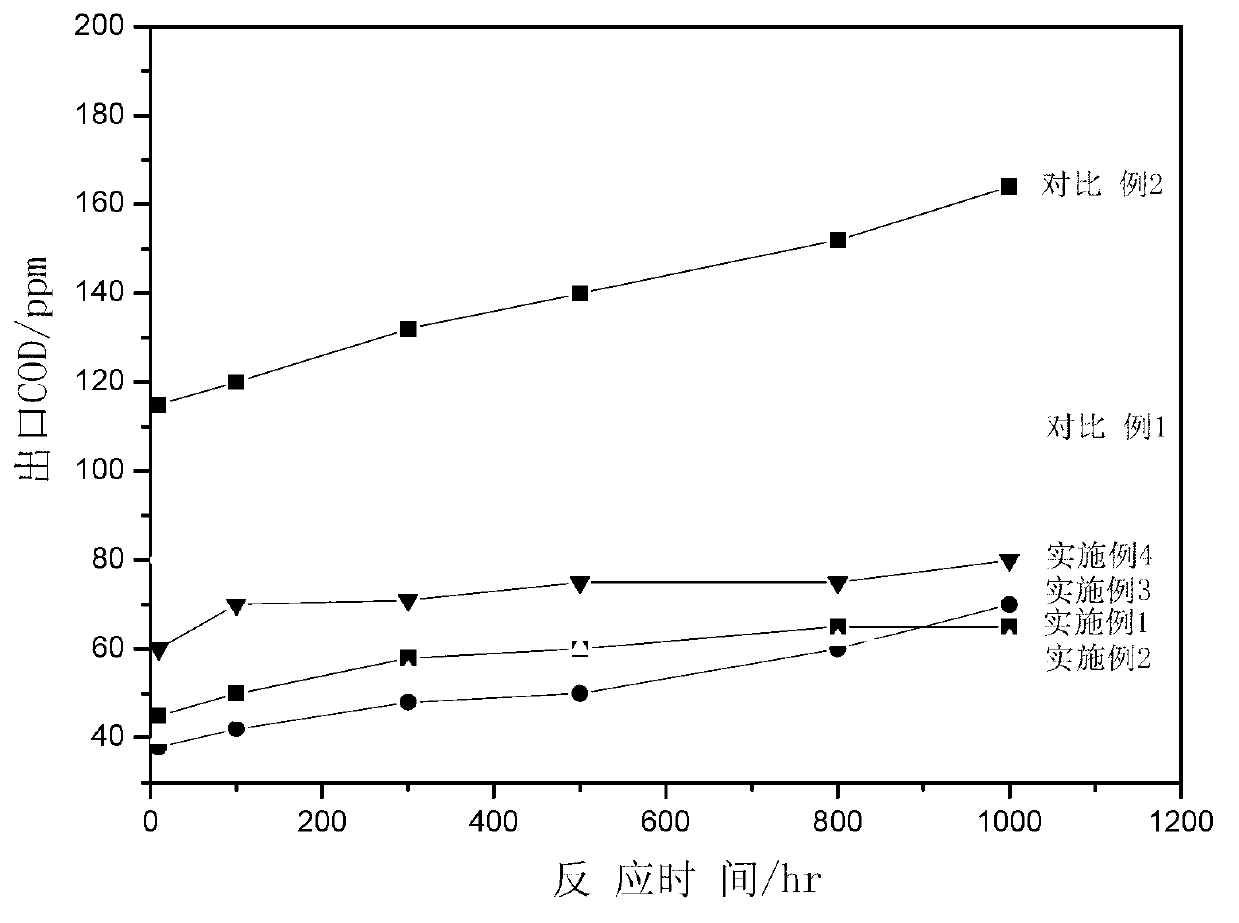

[0041] This catalyzer is tested with the method as in embodiment 1, and the evaluation result of its catalyzer sees figure 1 .

Embodiment 3

[0043] After the preparation of the active component solution, liquid phase deposition was carried out at 60° C. for 24 hours, and the rest of the catalyst preparation steps were the same as in Example 1. The content of catalyst active components is listed in Table 1.

[0044] This catalyzer is tested with the method as in embodiment 1, and the evaluation result of its catalyzer sees figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com