Preparation method of ultrahigh fatigue strength powder metallurgy titanium and titanium alloy

A technology of fatigue strength and powder metallurgy, which is applied in the field of powder metallurgy titanium, can solve the problems of inability to process materials, poor fatigue performance, and low fatigue strength, and achieve the effects of improving the difficulty of expansion, large sintering driving force, and improving powder activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

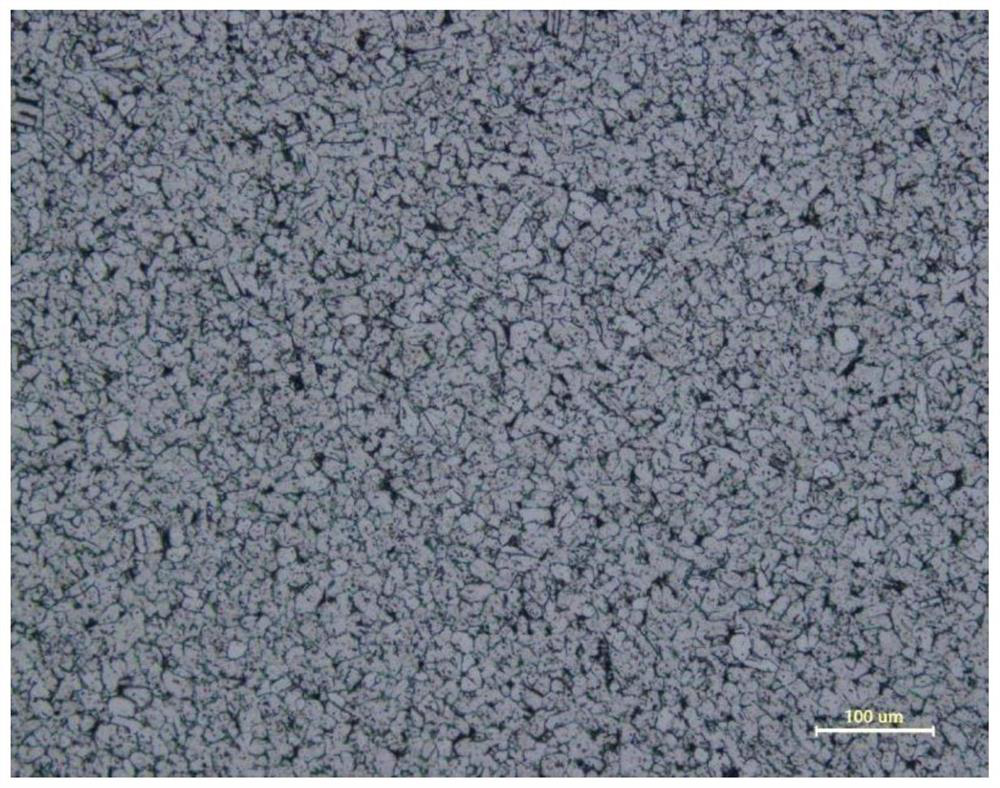

Image

Examples

Embodiment 1

[0031] A preparation method of powder metallurgy titanium and titanium alloy with ultra-high fatigue strength, the specific preparation steps are as follows:

[0032] (1) Put the titanium sponge into a hydrogen furnace for hydrogenation treatment, the hydrogenation temperature is 350°C, and keep it warm for 10 hours to obtain titanium hydrogenation material;

[0033] (2) Mix the hydrogenated material described in step (1) with 6wt.% aluminum powder (~50 μm) and 4wt.% vanadium powder (~50 μm), and perform high-energy ball milling with a ball-to-material ratio of 4:1, The ball milling time is 12 hours, and after crushing, ultrafine titanium hydride alloy powder with a particle size of 10 μm and an oxygen content of 500 ppm is obtained;

[0034] (3) Put the ultra-fine hydrogenated titanium alloy powder described in step (2) into a vacuum sintering furnace for dehydrogenation treatment, the vacuum degree is 1 Pa, the dehydrogenation temperature is 800 ° C, and it is kept for 4 hou...

Embodiment 2

[0040] A preparation method of powder metallurgy titanium and titanium alloy with ultra-high fatigue strength, the specific preparation steps are as follows:

[0041] (1) Put the titanium sponge into a hydrogen furnace for hydrogenation treatment at a hydrogenation temperature of 800°C and keep it warm for 3 hours to obtain titanium hydride material;

[0042] (2) Combine hydrogenated material described in step (1) with 6wt.% aluminum powder (~500 μm), 2wt.% zirconium powder (~500 μm), 1wt.% molybdenum powder (~500 μm), 1wt.% Vanadium powder (~500 μm) was mixed and subjected to high-energy ball milling. The ball-to-material ratio was 10:1, and the ball milling time was 48 hours. After crushing, ultrafine titanium hydride alloy powder with a particle size of 1 μm and an oxygen content of 1000 ppm was obtained;

[0043] (3) Put the superfine titanium hydride alloy powder described in step (2) into a vacuum sintering furnace for dehydrogenation treatment, vacuum degree 10 -3 Pa, ...

Embodiment 3

[0049] A preparation method of powder metallurgy titanium and titanium alloy with ultra-high fatigue strength, the specific preparation steps are as follows:

[0050] (1) Put the titanium sponge into a hydrogen furnace for hydrogenation treatment at a hydrogenation temperature of 600°C and keep it warm for 5 hours to obtain titanium hydride material;

[0051] (2) Carrying out high-energy ball milling to the hydrogenated material described in step (1), the ball-to-material ratio is 8:1, the ball milling time is 24h, and after crushing, the obtained particle size is 5 μm ultrafine titanium hydride powder, and the oxygen content is 400 ppm;

[0052] (3) Put the superfine titanium hydride powder described in step (2) into a vacuum sintering furnace for dehydrogenation treatment, vacuum degree 10 -2 Pa, the dehydrogenation temperature is 650°C, and the temperature is kept for 7 hours to obtain ultrafine hydrogenated dehydrogenation titanium powder with a particle size of 5 μm and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com