Preparing method for powder metallurgy titanium alloy

A powder metallurgy and titanium alloy technology, applied in the field of powder metallurgy titanium alloy preparation, can solve the problems of long hydrogen permeation time, unsafe operation, and the influence of sintered titanium alloy grain size and structure is rarely mentioned. The effect of increased density and increased tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

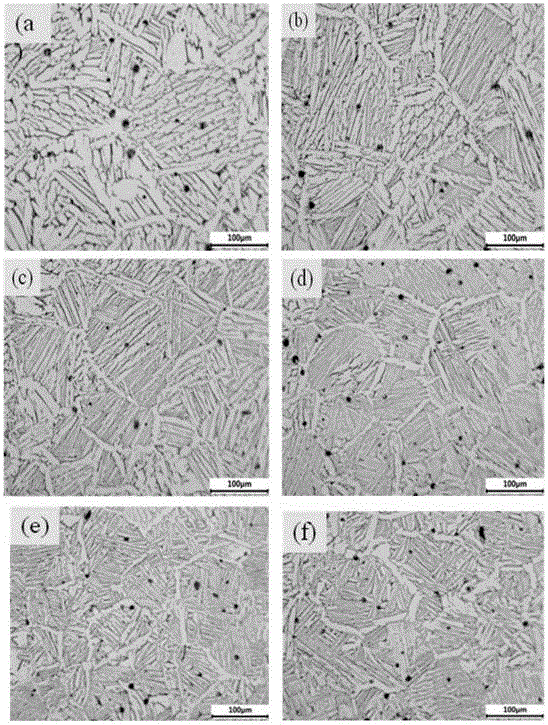

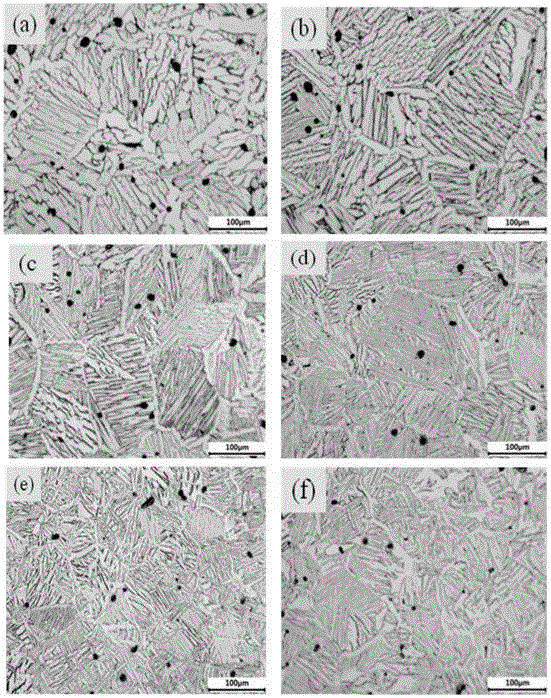

Examples

Embodiment 1

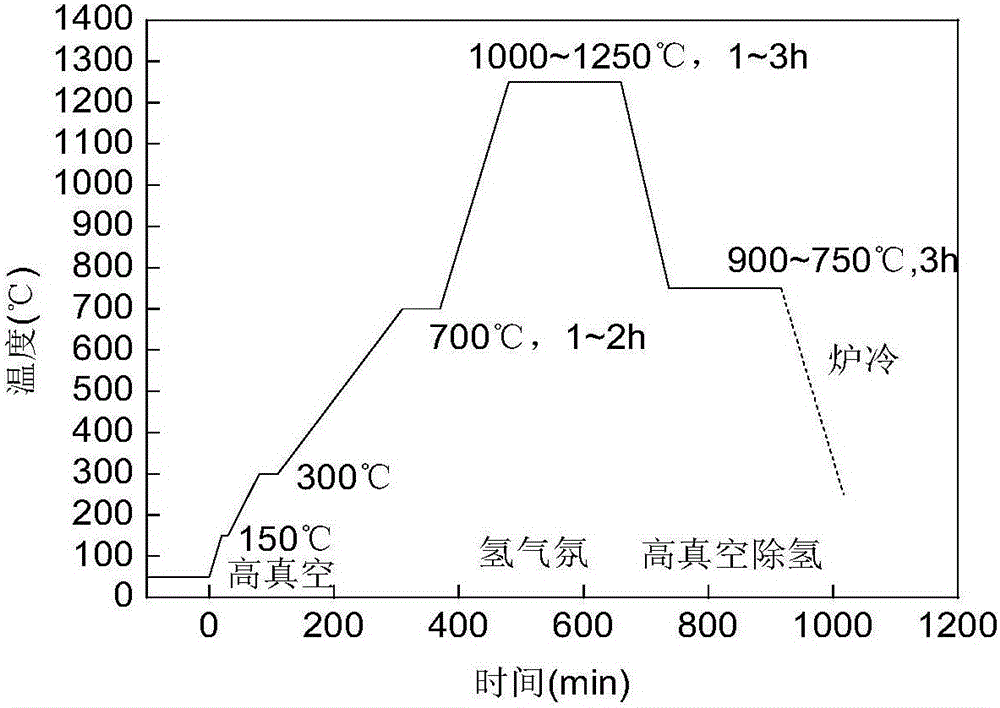

[0031] The steps of preparing powder metallurgy titanium alloy of the present embodiment are as follows:

[0032] (1) Ti powder with a particle size of -200 mesh and TiH with a particle size of -325 mesh 2 and Al6V4 master alloy powder with a particle size of -325 mesh as raw materials, prepared according to the target of the final sintered product being titanium six aluminum four vanadium titanium alloy.

[0033] Refer to the national standard GB / 3620.1-2007 to weigh the required raw material powder according to the stoichiometric ratio of Ti-6Al-4V titanium alloy, in which HDH titanium powder and Al-V master alloy are mixed at a mass ratio of 9:1, called No. 1 powder ; Titanium hydride powder and Al-V master alloy powder are mixed at a mass ratio of 9.38:1, called II powder; then I and II powders are mixed according to a certain ratio, and finally mixed powders with different hydrogen contents are obtained. Each mixing process is carried out in a DL-SHL-5L high-efficiency d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com