Sintered body of titanium compound

A technology of titanium compound and sintered body is applied in the fields of artificial bone, artificial tooth root material and artificial bone material, which can solve the problems of mixed sintering without titanium compound and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Next, the method for producing the sintered body of the titanium compound of the present invention will be described.

[0060] The sintered body of the titanium compound of the present invention can be produced by sintering the powder of the titanium compound at a temperature exceeding 800°C. At a temperature of 800° C. or lower, the titanium compound may not be sintered, or the sintered body after sintering may easily disintegrate.

[0061] The upper limit of the sintering temperature is not particularly limited as long as it is a temperature at which the titanium compound can be sintered, but the sintering is preferably performed at a temperature of 1500° C. or lower.

[0062] In addition, the sintered body of the titanium compound of the present invention preferably sinters the titanium compound in an inert gas atmosphere and / or under reduced pressure. The inert gas used here is preferably xenon and / or argon. In addition, the pressure during sintering is preferably...

Embodiment 1

[0078]

[0079] Dissolve 0.1 mole calcium nitrate (Ca(NO 3 ) 2 ) and 0.1 mole titanium sulfate (TiSO 4 ), neutralize with alkali. Next, add 0.06 molar phosphoric acid (H 3 PO 4 ), add ammonia water, adjust pH=9.0, and stir at 100° C. for 6 hours. The obtained precipitate was filtered and dried to obtain about 10 g of powder of the compound represented by formula (1) or formula (2).

Embodiment 2

[0081]

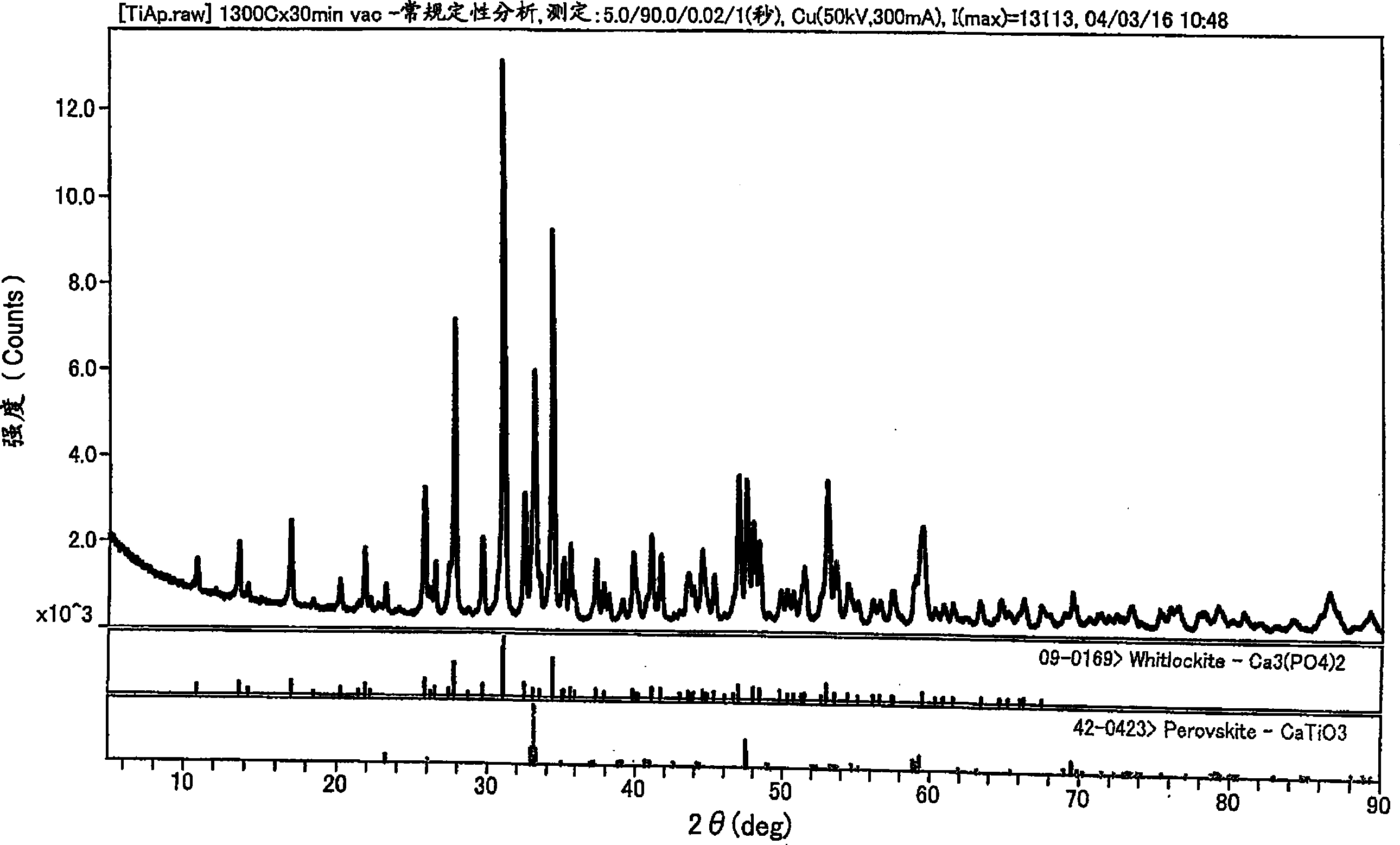

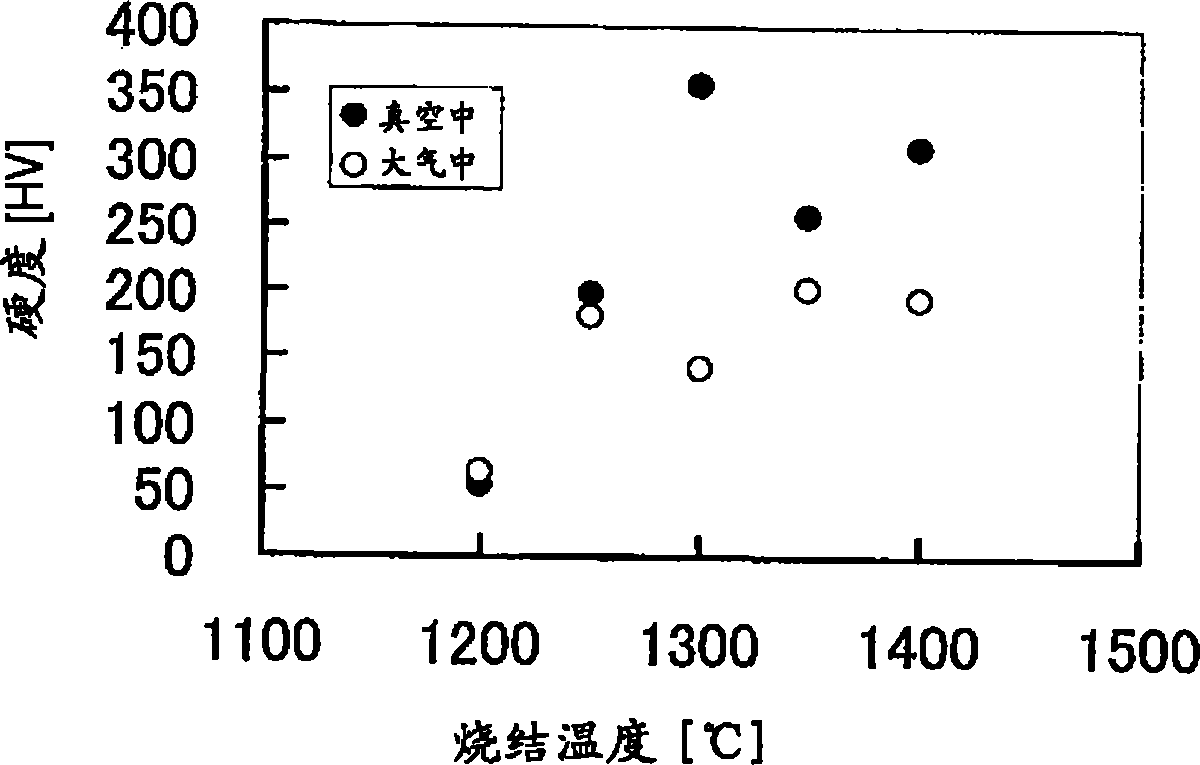

[0082] Stir about 3 g of the titanium compound powder obtained in Example 1 with distilled water, put it into a mold, and air-dry it after molding. The air-dried molded body was put into a desiccator, and dried at 100° C. for 24 hours. Put the dried sample into a vacuum heat treatment machine, under atmospheric pressure or in vacuum (10 -4 Pa), and kept at each temperature for 30 minutes to make it sintered. After stopping the heating, let it return to room temperature. In addition, the sample sintered in vacuum was left to stand, and after returning to room temperature, it sealed with argon gas, and took it out. The obtained sintered body of the titanium compound was subjected to crystal analysis by X-ray diffraction. figure 1 X-ray diffraction results of sintered compacts sintered at 1300°C in vacuum are shown. in addition, figure 1 The X-ray diffraction patterns of perovskite and perovskite are also shown in . The results are summarized in Table 1.

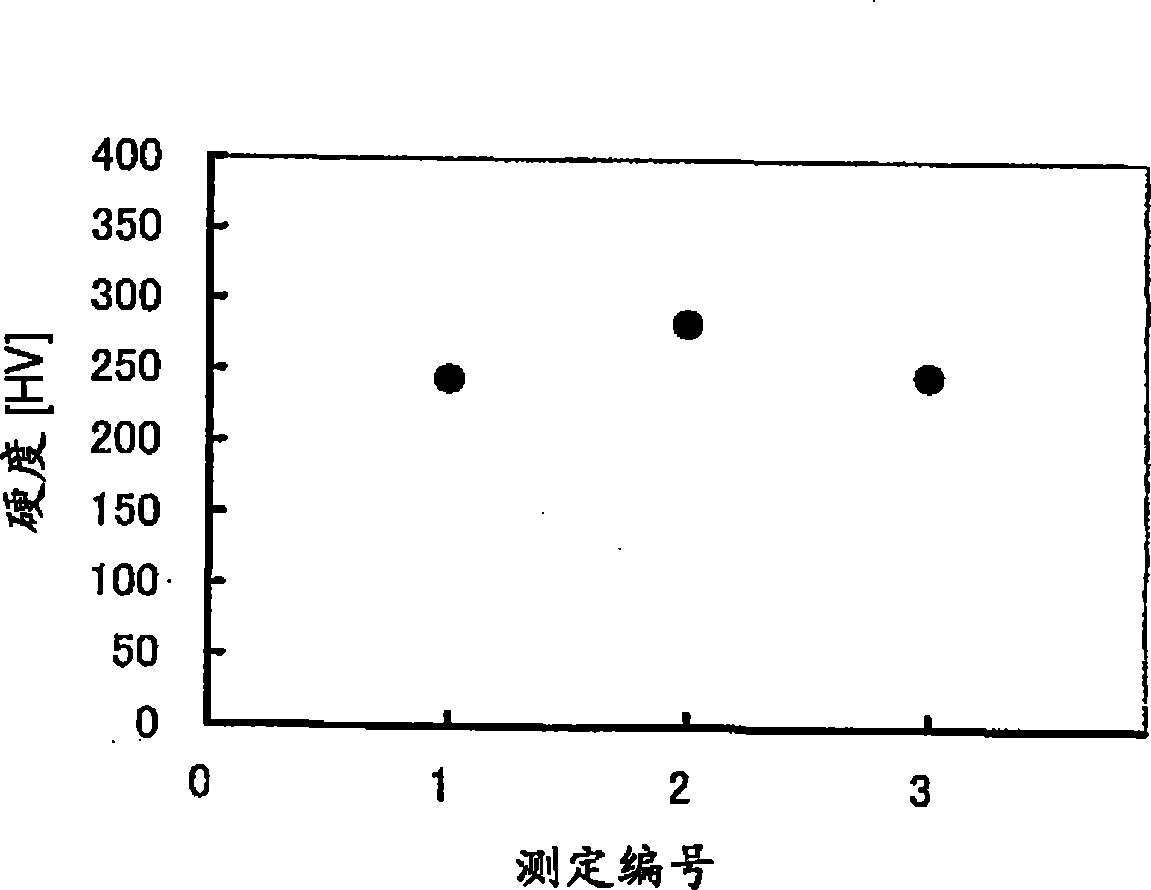

[0083...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com