Sintered titanium alloy and preparation method thereof

A titanium alloy, vacuum sintering technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of unfavorable alloy structure and performance, influence and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A "press-vacuum sintering" preparation method for sintering rare earth-like titanium alloys, comprising the following steps:

[0036] The first step: mixing powder

[0037] Take 200-400 mesh HDH titanium powder (oxygen content 0.25-0.40wt.%) and mix CeN powder (0.2-0.8wt.%) or NdN powder (0.2-0.8wt.%) with a powder particle size of 2-5 μm, mix The process was carried out under the protection of nitrogen at an atmospheric pressure.

[0038] Step 2: Compression molding

[0039] The mixed powder is placed in a mold and pressed into shape by a press, and the pressing pressure is 200-600Mpa.

[0040] Step 3: Sintering

[0041] Heat the pressed sample to 500°C-600°C at a heating rate of 2-10°C / min, keep it warm for 0.5-1h, and then raise the temperature to 1250°C-1380°C at a heating rate of 5-10°C / min, the vacuum degree is 1×10 -3 to 5×10 -4 Pa between.

[0042] A method for preparing a sintered titanium alloy, comprising the steps of:

[0043] The first step: mixing ...

Embodiment 1

[0056] The first step: mixing powder

[0057] 200 mesh HDH titanium powder (oxygen content 0.25wt.%) was mixed with CeN powder (0.4wt.%) or NdN powder (0.4wt.%) with a particle size of 5 μm, and the mixing process was carried out under the protection of nitrogen at an atmospheric pressure.

[0058] Step 2: Compression molding

[0059] The mixed powder is placed in a mold and pressed into shape by a press, and the pressing pressure is 200-600Mpa.

[0060] Step 3: Sintering

[0061] Heat the pressed sample to 500°C-600°C at a heating rate of 2-10°C / min, keep it warm for 0.5-1h, and then raise the temperature to 1250°C-1380°C at a heating rate of 5-10°C / min, the vacuum degree is 1×10 -3 to 5×10 -4 Pa between. The specific mechanical properties data are shown in Table 1.

[0062] Table 1 Example 1 sample mechanical property data summary

[0063]

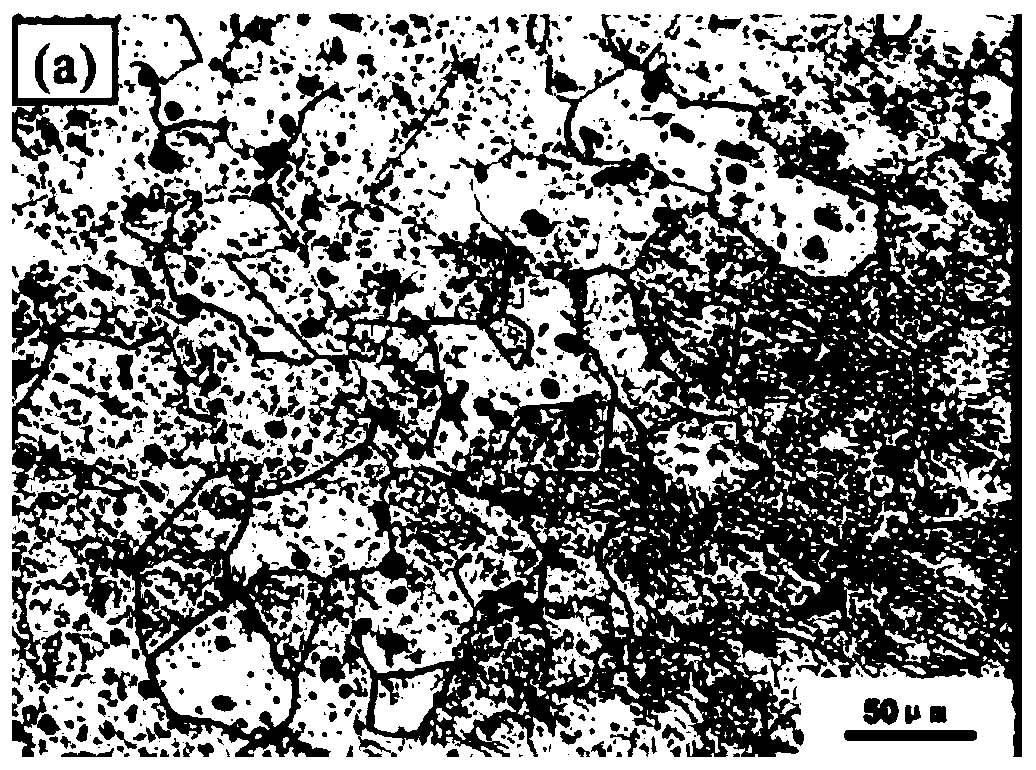

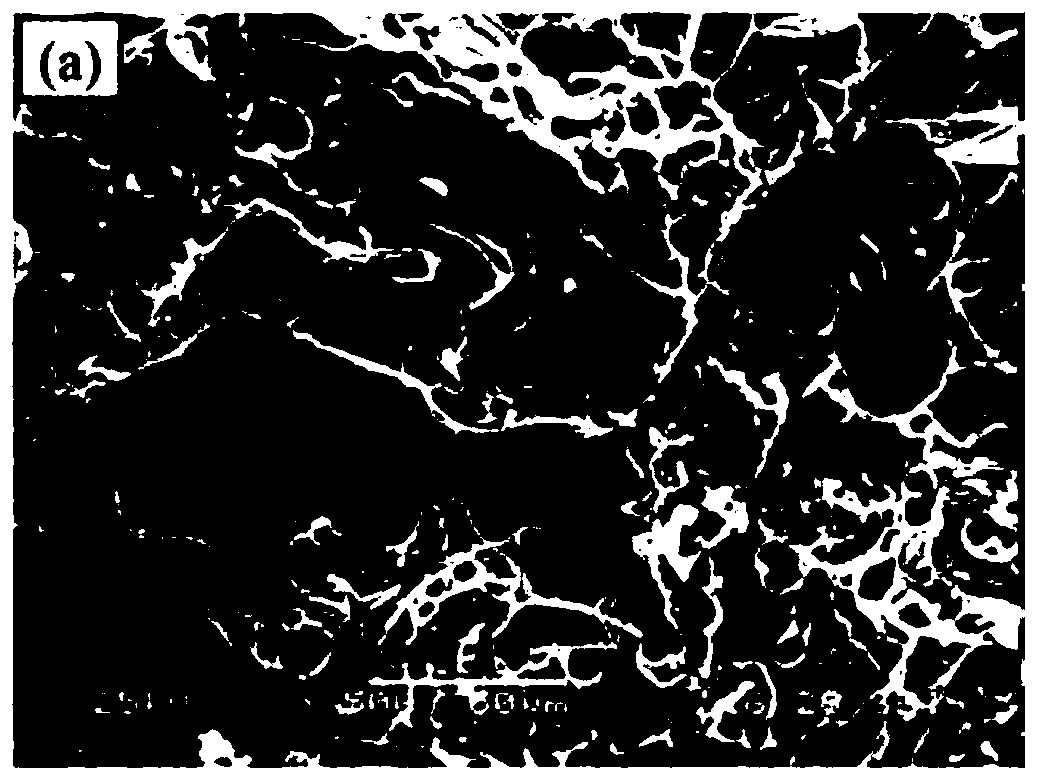

[0064] The sintering temperature of the present invention is above 1200°C. During sintering, the rare earth nitrides decompos...

Embodiment 2

[0066] The first step: mixing powder

[0067] 200-400 mesh HDH titanium powder (oxygen content 0.25-0.40wt.%) is mixed with NdN powder (0.2-0.8wt.%) with a particle size of 5 μm, and the mixing process is carried out under the protection of nitrogen at an atmospheric pressure.

[0068] Step 2: Compression molding

[0069] The mixed powder is placed in a mold and pressed into shape by a press, and the pressing pressure is 200-600Mpa.

[0070] Step 3: Sintering

[0071] Heat the pressed sample to 500°C-600°C at a heating rate of 2-10°C / min, keep it warm for 0.5-1h, and then raise the temperature to 1330°C at a heating rate of 5-10°C / min, with a vacuum of 5×10 -4 Pa. The specific mechanical properties data are shown in Table 2.

[0072] Table 2 Example 2 sample mechanical property data summary

[0073]

[0074] Adding a small amount of rare earth nitride powder can increase the relative density during the sintering process, but as the mass fraction of nitride powder conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com