Low-temperature sintered strontium titanate energy-storing medium ceramic material and preparation method thereof

A technology of energy storage media and ceramic materials, which is applied in the field of ceramic compositions, can solve problems such as strontium titanate-based ceramics that have not yet been seen, and achieve the effect of low sintering temperature and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

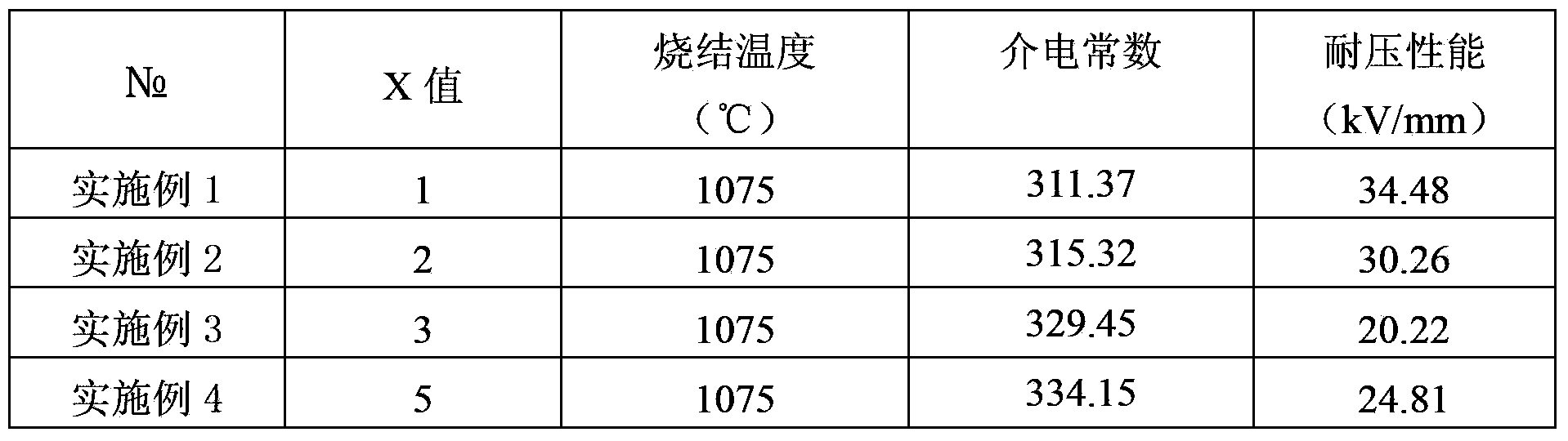

Examples

Embodiment Construction

[0022] The raw materials used in the present invention are all commercially available analytical reagents, and the specific embodiments are as follows.

[0023] (1) According to the stoichiometric formula (Sr 0.9 Mg 0.1 )(Ti 0.96 Zr 0.04 )O 3 , the raw material SrCO 3 , MgO, TiO 2 and ZrO 2 Weigh the ingredients. Put the mixed powder into a polyester tank, add deionized water and zirconia balls, the mass ratio of material, water, and balls is 1:1:1, and mill on a planetary ball mill for 6-12 hours at a speed of 1000 rpm / Minute. Then the ball-milled raw materials are dried in a 1500W infrared drying oven, and the raw materials are passed through a 40-mesh sieve after drying. The sieved powder is pre-fired at 1125°C and kept at this temperature for 4 hours to synthesize the main crystal phase.

[0024] (2) According to the stoichiometric formula, it is BaCuB 2 o 5 , the raw material BaCO 3 , CuO and B 2 o 3 Weigh the ingredients. Put the mixed powder into a poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com