Easy-to-sinter titanium and tungsten co-doped zirconium carbide powder and preparation method thereof

A zirconium carbide powder and co-doping technology, which is applied in the field of ultra-high temperature ceramics, can solve the problems that high-energy ball milling is not suitable for preparing a large number of powders, high oxygen content of zirconium carbide ceramic powder, complex metal impurity removal process, etc., to achieve oxygen content Low, low equipment requirements, small grain size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

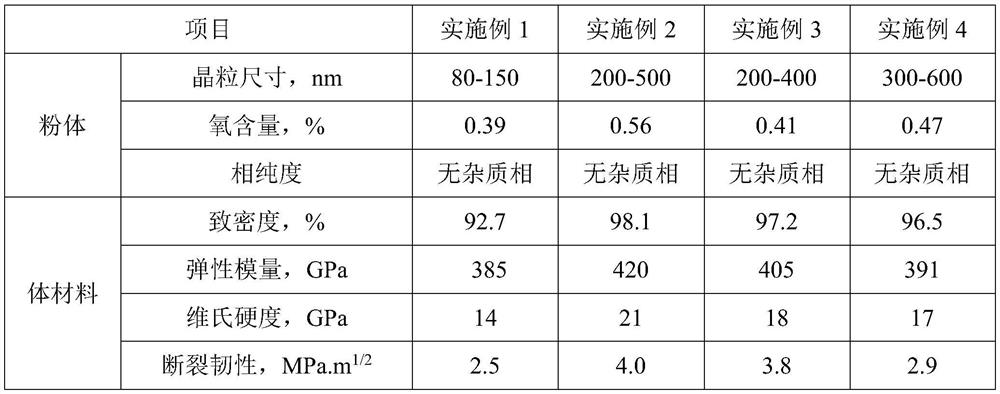

Embodiment 1

[0033] (1) the raw material ZrO 2 、TiO 2 and WO 3 Powder and carbon black according to ZrO 2 :TiO 2 :WO 3 : The molar ratio of carbon black=0.91:0.06:0.03:3.21 is weighed, then placed in the zirconia mixing tank, adding dehydrated alcohol, making the ball milling medium with zirconia balls, mixing 12h at 90r / min rotating speed;

[0034] (2) Put the uniformly mixed raw materials into a vacuum drying oven, and dry them at a constant temperature of 30°C for 24 hours;

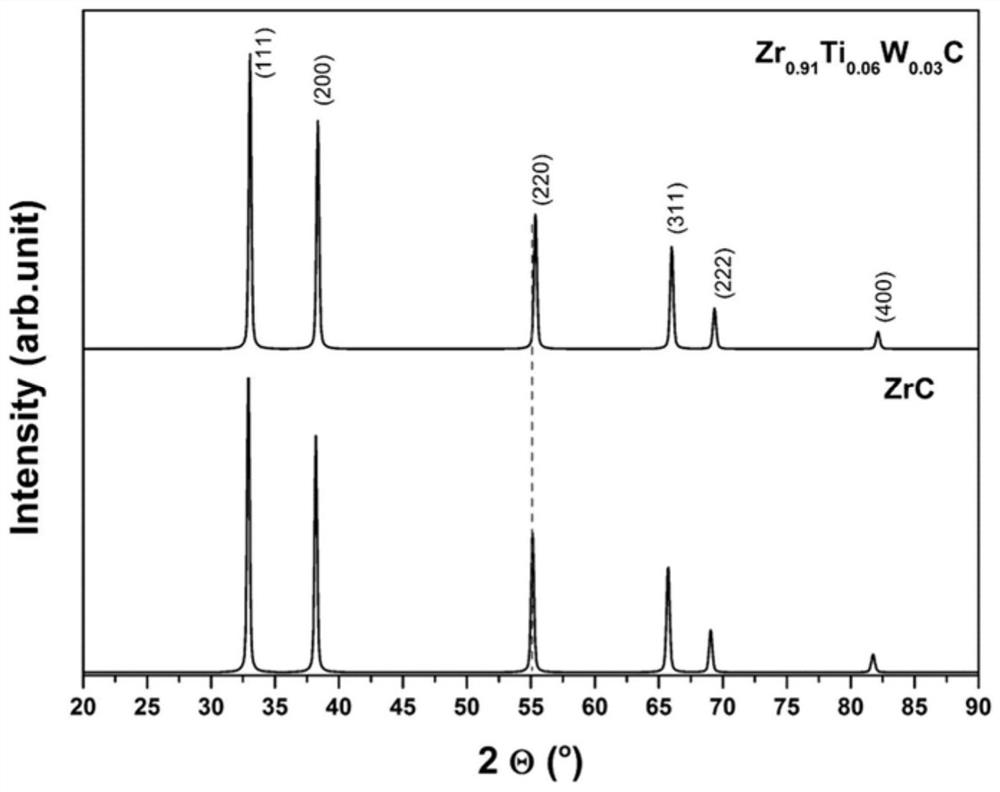

[0035] (3) Dry press the dried raw material powder into a graphite crucible, heat it to 1450°C at a rate of 15°C / min in a vacuum graphite furnace, keep it warm for 3 hours, cool down to room temperature with the furnace, and grind the obtained powder X-ray diffraction analysis shows that it is pure titanium and tungsten co-doped zirconium carbide Zr 0.91 Ti 0.06 W 0.03 C solid solution powder, no impurity phase, such as figure 1 shown.

[0036] From figure 1 It can be seen that due to the small covalent ...

Embodiment 2

[0039] (1) the raw material ZrO 2 、TiO 2 and WO 3 Powder and carbon black according to ZrO 2 :TiO 2 :WO 3 : The molar ratio of carbon black=0.90:0.08:0.02:3.21 is weighed, then placed in the zirconia mixing tank, adding dehydrated alcohol, making the ball milling medium with zirconia balls, mixing 15h at 120r / min rotating speed;

[0040] (2) Put the homogeneously mixed raw materials into a vacuum drying oven, and dry at a constant temperature of 28°C for 36 hours;

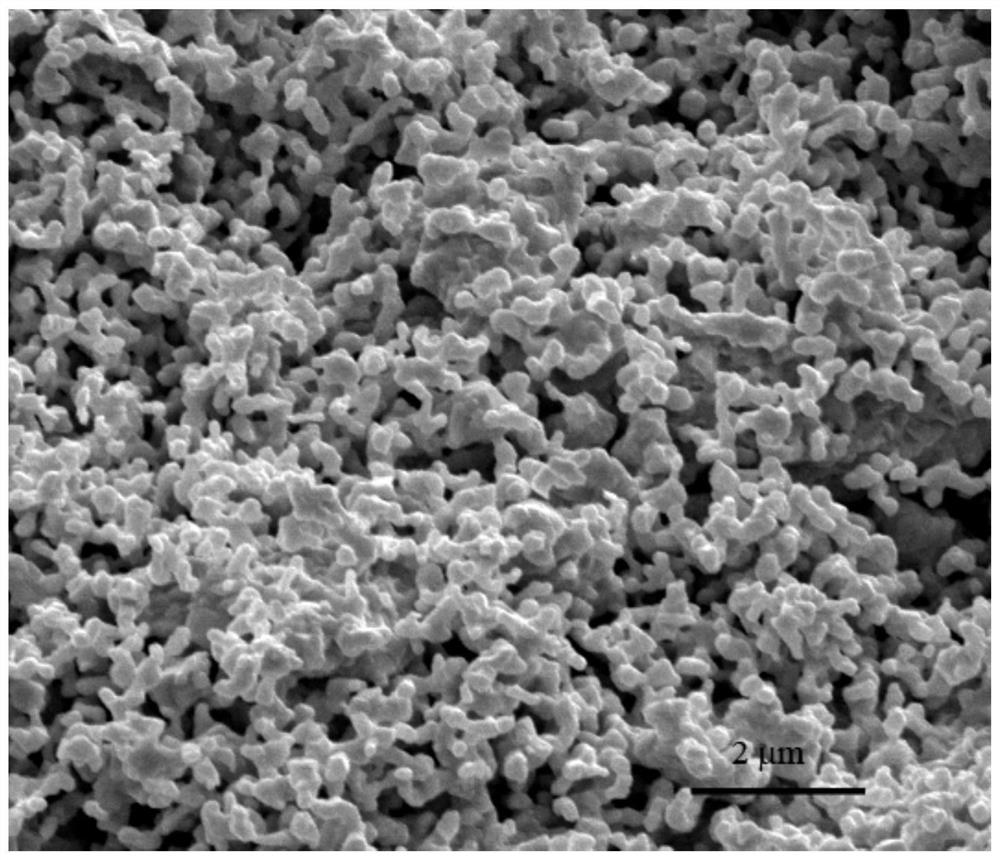

[0041] (3) Dry press the dried raw material powder into a graphite crucible, heat it to 1580°C at a rate of 20°C / min in an argon graphite furnace, keep it warm for 1h, cool to room temperature with the furnace, and grind the obtained powder The body is pure titanium and tungsten co-doped zirconium carbide Zr 0.90 Ti 0.08 W 0.02 C solid solution powder, its scanning electron microscope picture is as follows figure 2 shown.

[0042] From figure 2 It can be seen that titanium and tungsten co-doped zirconi...

Embodiment 3

[0045] (1) the raw material ZrO 2 、TiO 2 and WO 3 Powder and carbon black according to ZrO 2 :TiO 2 :WO 3 : the molar ratio of carbon black=0.85:0.10:0.05:3.21 is weighed, then placed in the zirconia mixing tank, adding dehydrated alcohol, making the ball milling medium with zirconia balls, mixing 20h at 150r / min rotating speed;

[0046] (2) Put the homogeneously mixed raw materials into a vacuum drying oven, and dry at a constant temperature of 25°C for 36 hours;

[0047] (3) Dry press the dried raw material powder into a graphite crucible, heat it to 1500°C at a rate of 15°C / min in a vacuum graphite furnace, keep it warm for 2h, cool to room temperature with the furnace, crush and grind the obtained The powder is pure titanium and tungsten co-doped zirconium carbide Zr 0.85 Ti 0.10 W 0.05 C solid solution powder, the grain size is 200-400nm.

[0048] Codoping titanium and tungsten with zirconium carbide Zr 0.85 Ti 0.10 W 0.05 The C powder was dry-pressed at 80MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com