Titanium-based alloy induction melting bottom leakage type vacuum suction casting device and control method

A titanium-based alloy and vacuum suction casting technology, which is applied in the field of titanium-based alloy melting and suction casting, can solve the problems of difficult preparation, high safety hazards, and large workload, so as to eliminate safety hazards, reduce labor intensity and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

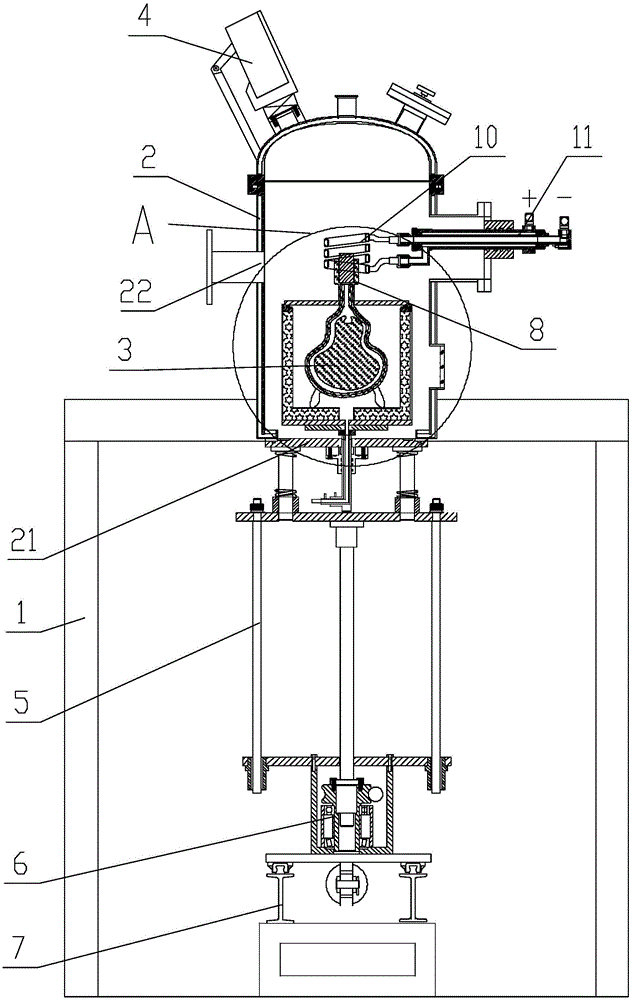

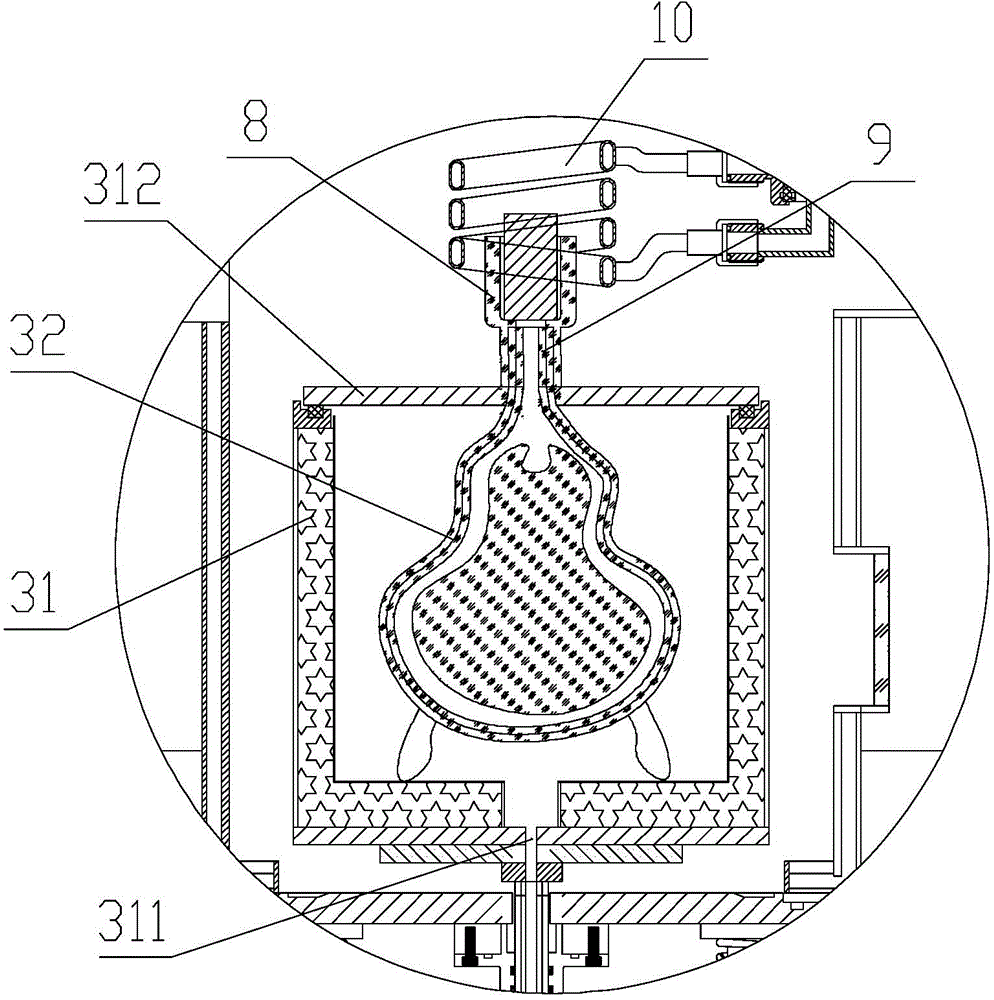

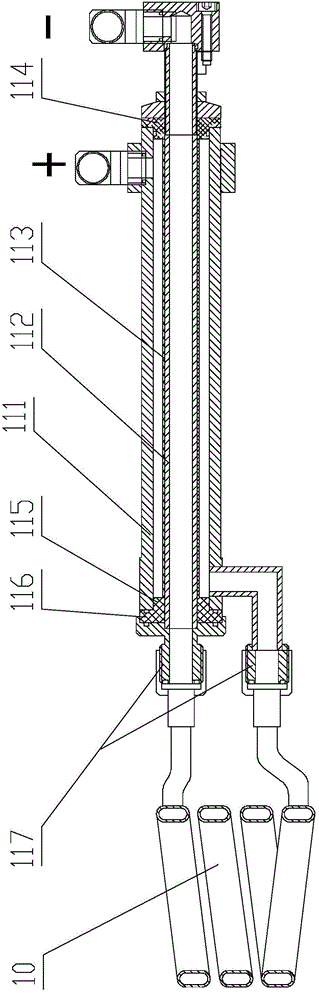

[0065] This embodiment provides a bottom-drain vacuum suction casting equipment for induction melting of titanium-based alloys, such as figure 1 and figure 2 As shown, the equipment includes a furnace body support 1 , an outer furnace body 2 supported on the furnace body support 1 , and a vacuum suction casting device 3 arranged in the outer furnace body 2 . The outer furnace body 2 is provided with an optical monitoring and temperature measuring device 4 for monitoring the temperature inside the outer furnace body 2 . There is a first vacuum port 22 on the side wall of the outer furnace body 2, and a vacuum unit is connected to the first vacuum port 22. When the furnace door 21 of the outer furnace body is closed, an airtight space is formed in the outer furnace body 2. Vacuuming can be carried out in the outer furnace body 2 through the vacuum unit.

[0066] In this embodiment, the furnace door 21 of the outer furnace body is arranged at the bottom of the outer furnace bo...

Embodiment 2

[0084] This embodiment provides a ceramic crucible for induction melting of a titanium-based alloy. The ceramic crucible includes a crucible body and an isolation layer attached to the inner surface of the crucible body.

[0085] In this embodiment, the material of the isolation layer contains yttrium oxide, which is very inert to titanium metal at high temperature and will not chemically react with it, and can isolate possible reactions with titanium metal during the smelting process. Advanced ceramic materials ensure the reliable smelting of titanium-based alloys. The material of the crucible body contains silicon dioxide, which can resist possible metal expansion and thermal stress during the melting process and ensure the strength of the crucible.

[0086]The size of the ceramic crucible is adjusted according to the actual amount of cast metal. The diameter of the inner cavity is usually 20 to 70 cm, preferably 30-60 cm, and the height is usually 40 to 150 cm, preferably 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com