Manufacture of lightweight metal matrix composites with controlled structure

a technology of metal matrix composites and controlled structure, which is applied in the field of manufacturing of lightweight metal matrix composites with controlled structure, can solve the problems of low dynamic mechanical properties that limit the application of immc, weak at high temperatures, and insufficient flexure, fatigue and impact strength of infiltrated mmc (immc), and achieves the effects of increasing mechanical properties such as elongation, toughness, flexure and impact strength or fatigue resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

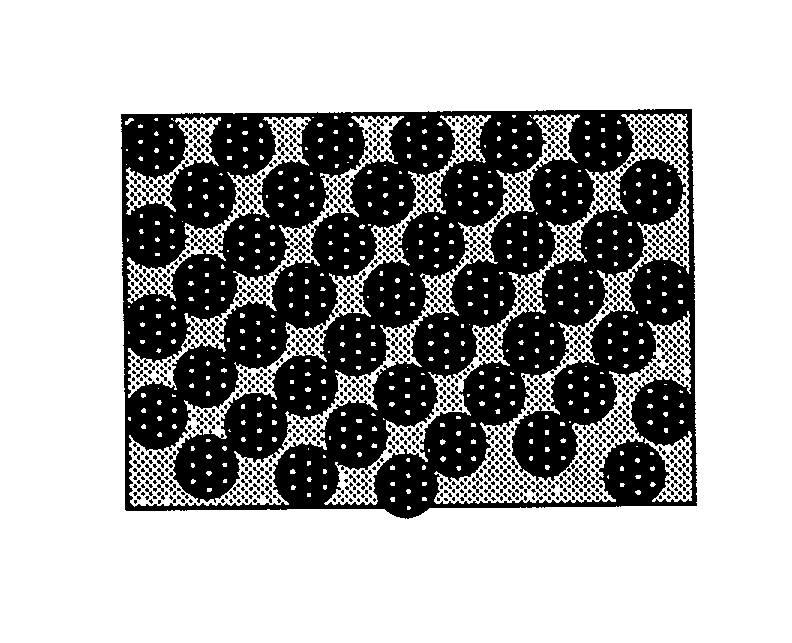

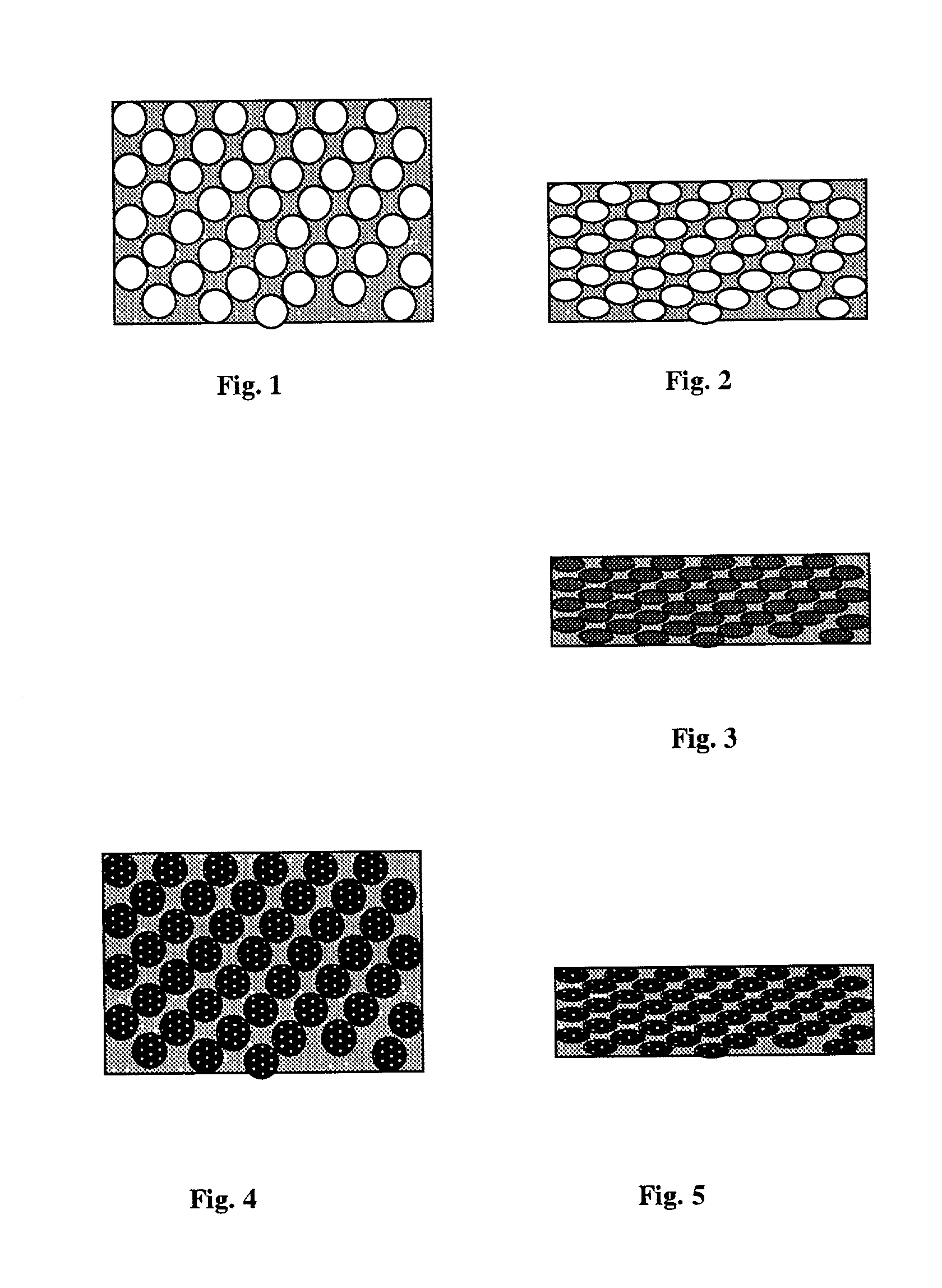

Image

Examples

example 1

[0048] The CP titanium powder having a particle size of -100 mesh was loose sintered at 1100.degree. C. (2000 F) in the flat preform having sizes of 6".times.12".times.0.125". The skeleton structure, having a density of 35% obtained after loose sintering was cold rolled to an average density of .about.50%. The infiltrating alloy with a composition of Mg-50 wt. %Al was placed on the preform in a graphite crucible and heated in vacuum to 600.degree. C. (1110 F) to infiltrate said titanium skeleton structure. The obtained composite material was fully dense with a measured density of 2.87-2.89 g / cm.sup.3.

[0049] Specimens 3".times.0.5" were cut out from the edge and central part of the sheet to measure hardness and flexure strength. The thickness of specimens was in the range of 0.078-0.125" depending on the preset deformation.

[0050] The particle size of titanium powder, sizes of initial powder preforms, loose sintering temperature, and sizes of specimens for mechanical testing were the ...

example 2

[0052] The same skeleton structure as in Example 1 was manufactured and infiltrated with the same Mg--50Al alloy melt. The infiltrated sheet was cold rolled to a 30% reduction. The resulting composite material had a measured density of 3.03-3.07 g / cm.sup.3 with a fully dense textured microstructure.

example 3

[0053] The same skeleton structure as in Example 1 was manufactured and infiltrated with the same Mg--50Al alloy melt. The infiltrated sheet was annealed for 4 h at 400.degree. C. (760 F) in vacuum to promote the formation of strengthening intermetallic phases. Measured density of the resulting composite was 2.86-2.89 g / cm.sup.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com