Method for manufacturing spherical niobium and titanium-based alloy powder with small particle size

A technology based on alloy and fine particle size, which is applied in the field of powder metallurgy, can solve the problems of low sphericity and low oxygen content, and achieve the effects of high spheroidization rate, reduced powder oxidation, and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

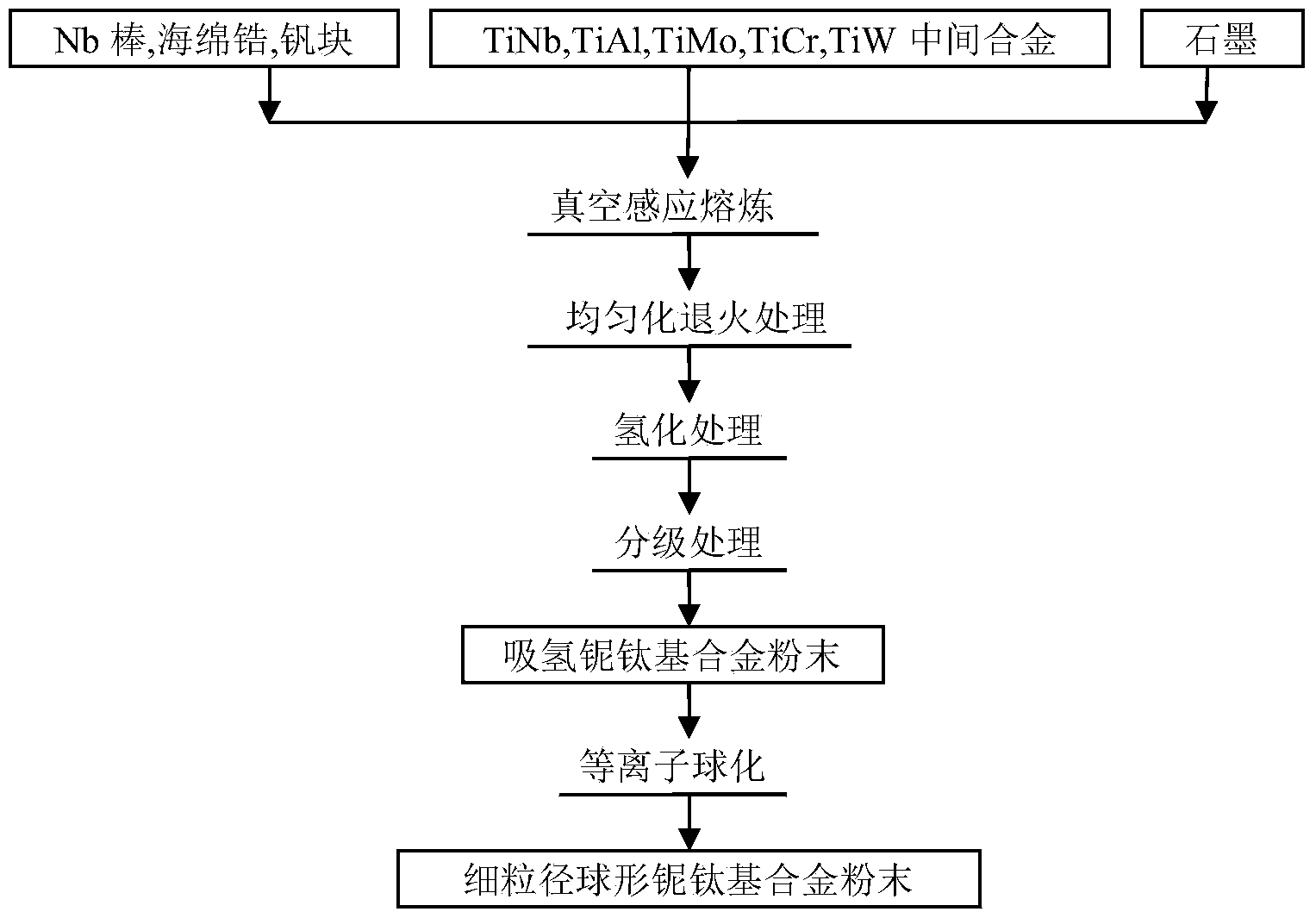

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Preparation of fine spherical Nb-45%Ti-3%Mo-0.5%Zr powder with an average particle size of 21 μm

[0014] The following raw materials were weighed according to the composition of the niobium-titanium-based alloy: TiNb master alloy, TiMo master alloy, zirconium sponge and Nb rod. The mass percent content of Ti, Mo, Zr and Nb elements in the niobium-titanium alloy is 45% Ti, 3% Mo, 0.5% Zr and the balance Nb. Preheat the metal mold to 350°C before smelting, increase the melting power of the water-cooled copper crucible vacuum induction melting furnace by 190kW and stop increasing the power, then melt at a constant power for 1min to obtain a melt, and obtain a niobium-titanium-based alloy casting after cooling Ingot; niobium-titanium alloy ingot in vacuum degree ≦ 10 -2 Homogenization annealing treatment is carried out in a vacuum furnace of Pa, the temperature of the homogenization annealing treatment is 800°C, and the holding time is 3 hours to obtain a niobi...

Embodiment 2

[0015] Example 2: Preparation of fine spherical Nb-40%Ti-6%Mo-1.5%Zr powder with an average particle size of 32 μm

[0016] The following raw materials were weighed according to the composition of the niobium-titanium-based alloy: TiNb master alloy, TiMo master alloy, zirconium sponge and Nb rod. The mass percentages of Ti, Mo, Zr and Nb in the niobium-titanium alloy are 40% Ti, 6% Mo, 1.5% Zr and the balance Nb. Preheat the metal mold to 400°C before melting, increase the melting power of the water-cooled copper crucible vacuum induction melting furnace by 180kW and stop increasing the power, then melt at a constant power for 2 minutes to obtain a melt, and obtain a niobium-titanium-based alloy casting after cooling Ingot; niobium-titanium alloy ingot in vacuum degree ≦ 10 -2 Homogenizing annealing treatment is carried out in a Pa vacuum furnace, the temperature of the homogenizing annealing treatment is 900°C, and the holding time is 2 hours to obtain a niobium-titanium-bas...

Embodiment 3

[0017] Example 3: Preparation of fine spherical Nb-20%Ti-4%Al-3%Cr-5%V-4.5%W-0.03%C powder with an average particle size of 15 μm

[0018] The following raw materials were weighed according to the composition of the niobium-titanium-based alloy: TiNb master alloy, TiAl master alloy, TiCr master alloy, TiW master alloy, V block and Nb rod. The contents of various alloying elements in the niobium-titanium alloy are: 20% Ti, 4% Al, 3% Cr, 5% V, 4.5% W, 0.03% graphite and the balance Nb. Preheat the metal mold to 380°C before smelting, increase the melting power of the water-cooled copper crucible vacuum induction melting furnace by 170kW and stop increasing the power, then melt at a constant power for 3 minutes to obtain a melt, and obtain a niobium-titanium-based alloy casting after cooling Ingot; niobium-titanium alloy ingot in vacuum degree ≦ 10 -2 Homogenization annealing treatment is carried out in a Pa vacuum furnace, the temperature of the homogenization annealing treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com