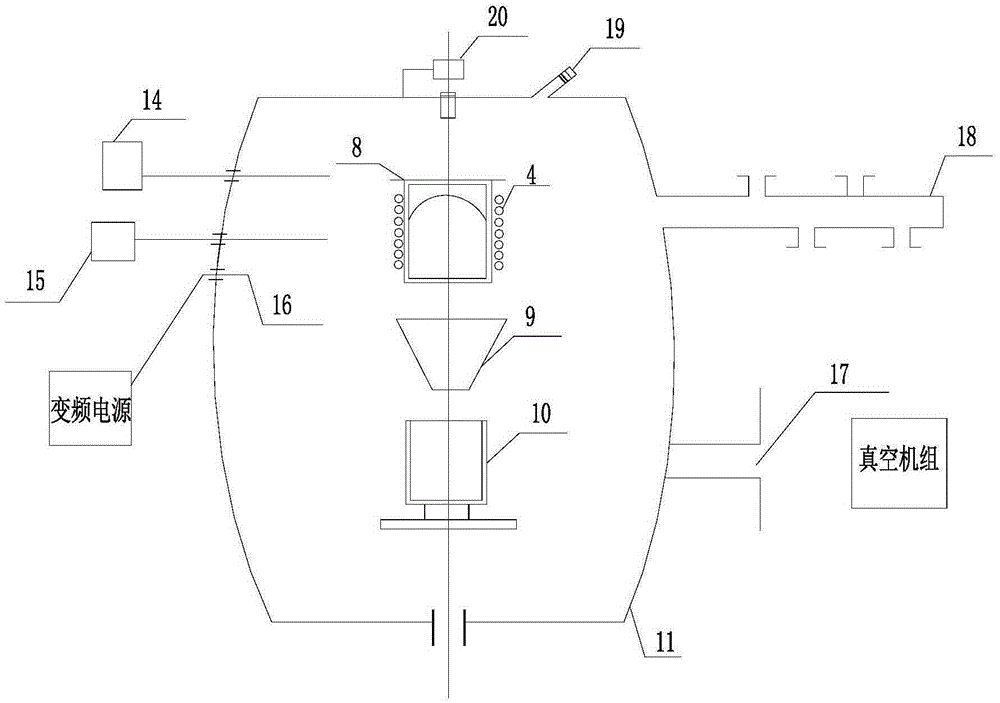

Electromagnetic induction vacuum device for titanium-based alloy smelting and mix-melting

An electromagnetic induction and titanium-based alloy technology, which is applied in the field of smelting and fusion technology application equipment, can solve the problems of high quality requirements, low oxygen content of titanium alloys, and the precision of alloy components cannot meet the requirements, so as to improve the composition Uniformity of distribution and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

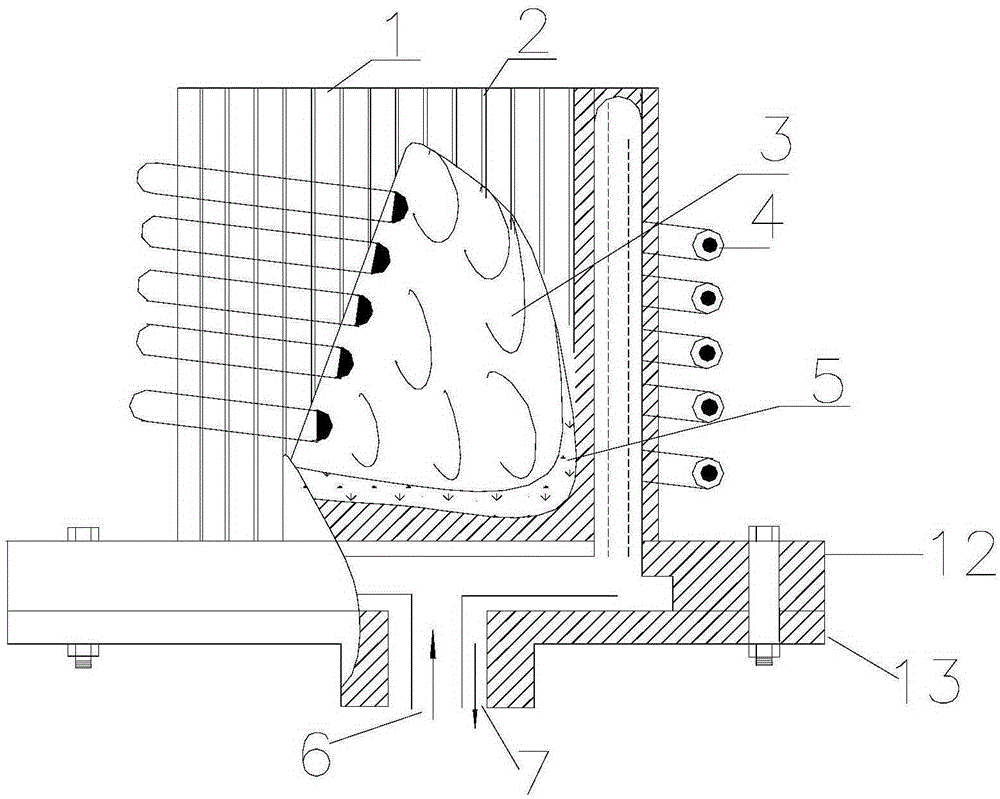

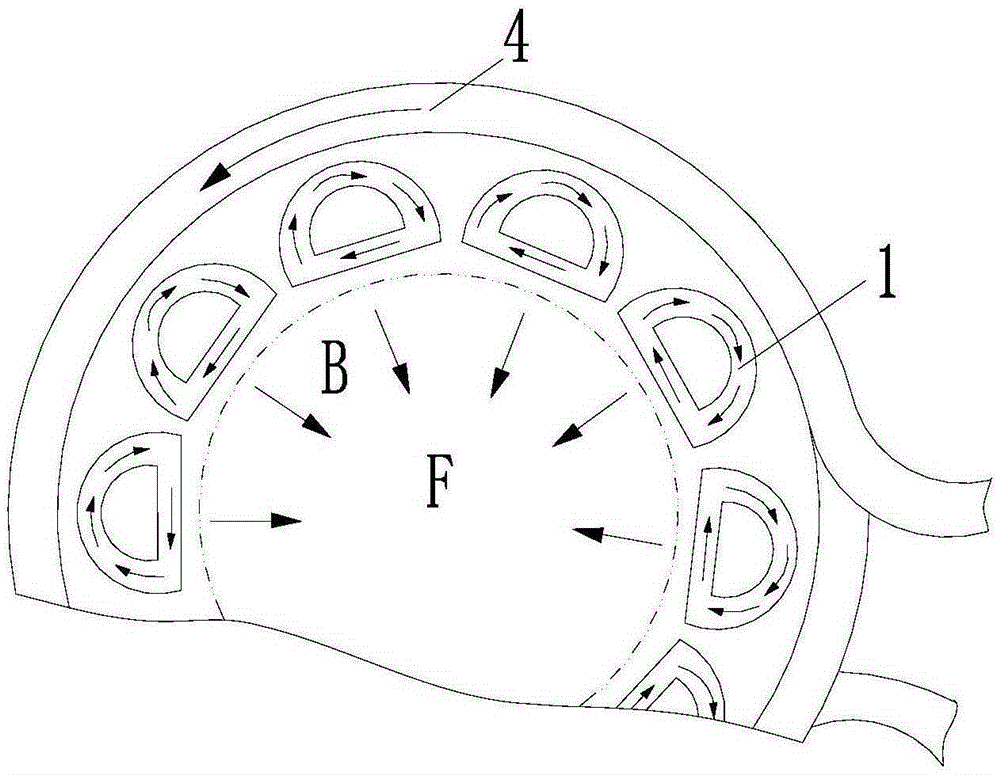

Method used

Image

Examples

Embodiment

[0042] 1. Electrical design basis of electromagnetic induction vacuum device for titanium-based alloy fusion

[0043] ①. Calculate the load power consumption, that is, the heat loss capacity of the power supply system according to the production volume required for titanium-based alloy smelting and melting, and then calculate according to the empirical value of 50Xnkw / kg, that is, the electricity consumption capacity of 50kw per kilogram of titanium-based alloy; the minimum The power meets the power requirements for step heating; refer to the calculation formula of electromagnetic induction heating heat; Q=cTG or electric power calculation formula: The average specific heat melting of titanium or titanium-based alloy; T, the rising temperature of smelting, G, the total mass of titanium or titanium-based alloy; t, the time s required to rise to T temperature, 0.24, thermal work equivalent;

[0044] ② The unit power absorbed by the titanium alloy charge is based on K, constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com