Automatic injection molding die

An injection mold and mold splitting technology, which is applied in the field of plastic product manufacturing, can solve problems such as poor mold release effect, low efficiency, and difficulty in mold release with ordinary injection molding machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

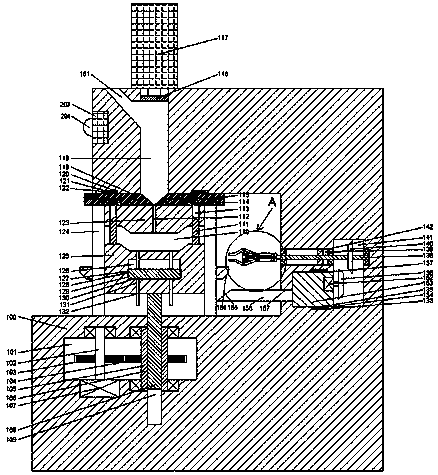

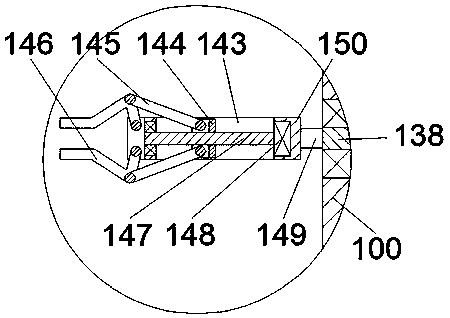

[0021] Such as Figure 1-Figure 2As shown, an automatic injection mold of the present invention includes a fuselage 100, a first cavity 110 disposed in the fuselage 100 that opens to the left, and an illumination device disposed in the lower end surface of the fuselage 100. There is a lower parting mold 125 that can slide up and down in the first cavity 110. The lower parting mold 125 is left-right symmetrical and front-back symmetrically provided with a first through hole that penetrates up and down. The first through hole is slidably fitted with a The first sliding rod 124 extending up and down, the upper and lower ends of the first sliding rod 124 are fixedly connected to the upper and lower end walls of the first cavity 110 respectively, and the lower parting mold 125 is provided with a first sliding cavity 126 , the first sliding block 130 is provided to slide up and down in the first sliding cavity 126, and the second through holes are symmetrically arranged in the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com