Vacuum glue injection device and glue injection method of capacitor

A technology of glue injection device and capacitor, which is applied to the device and coating of the surface coating liquid, which can solve the problems of large flow resistance, micro leakage of the delivery pump, easy suction and flattening, etc., and achieve the effect of consistent air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

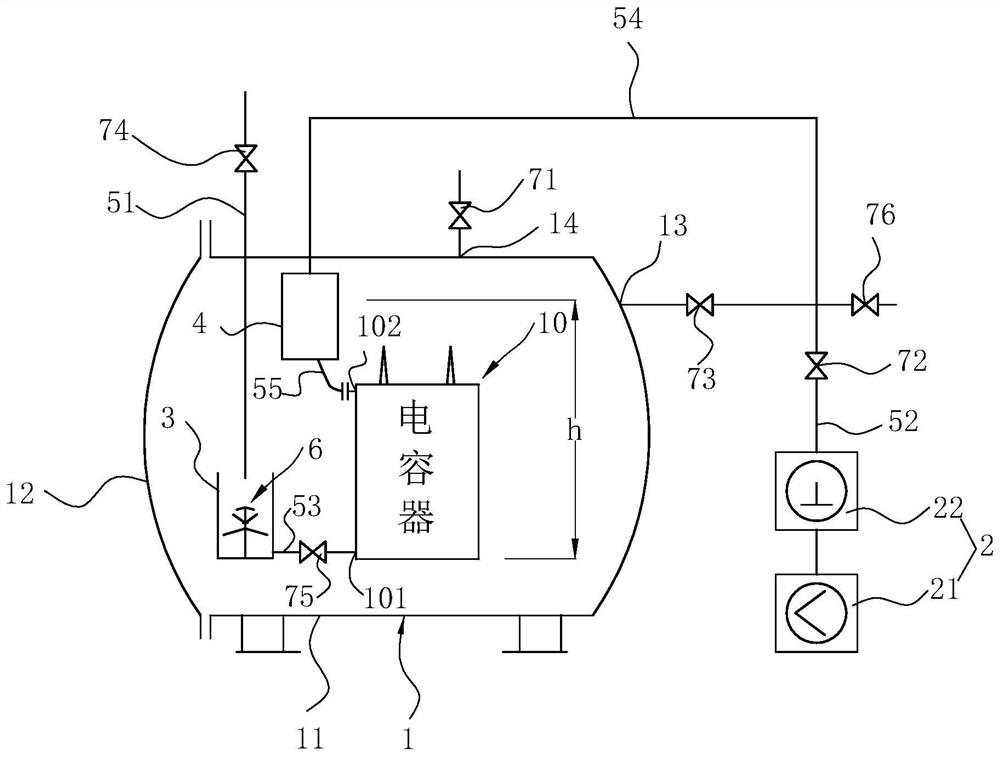

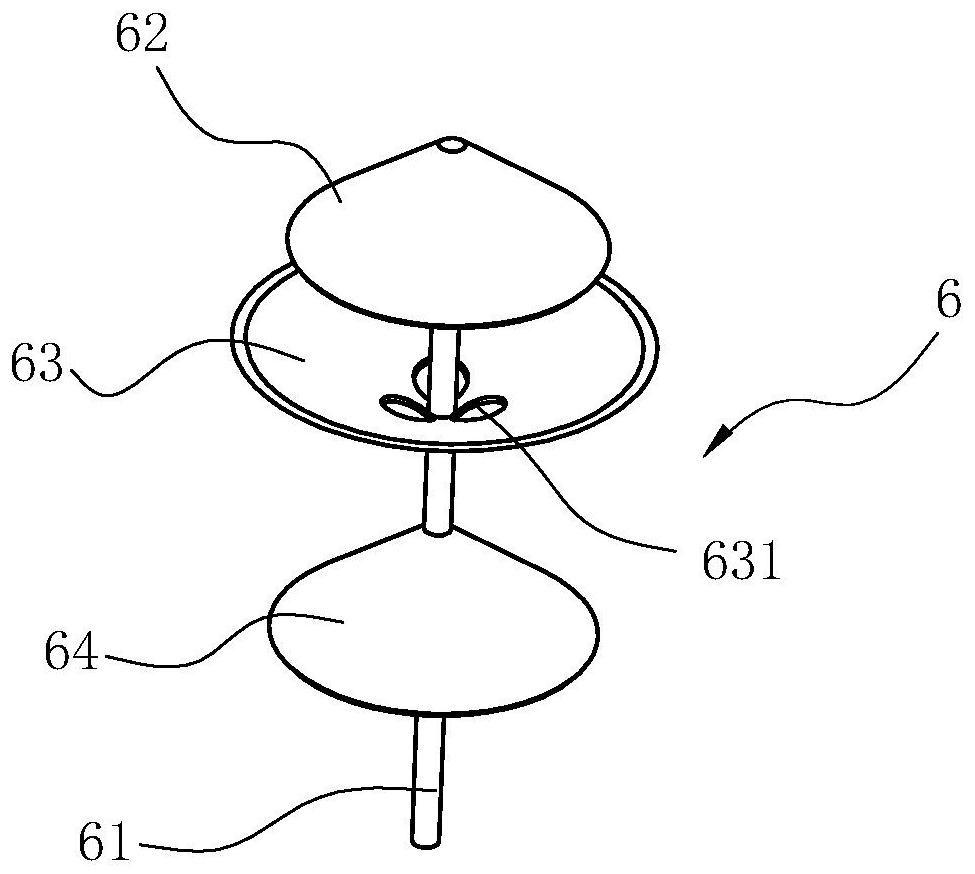

[0030] like figure 1 and figure 2 Shown is a preferred embodiment of the glue injection device of the present invention. The vacuum glue injection device of the capacitor includes a glue injection tank 1, a vacuum pump 2, a degassing barrel 3, a glue filling tank 4, and a glue injection tube 51, wherein the glue injection tank 1 can accommodate at least one capacitor 10, and the glue injection tank 1 The specific size of the volume can be set according to production needs. For simplicity and convenience of description, only one capacitor is shown in the figure. The glue injection tank 1 can adopt a conventional vacuum tank structure, that is, a tank door 12 that is sealed with the tank body 11 is configured, and the tank body 11 is provided with an air extraction port 13, an air release port 14 controlled by an air release valve 71, and a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com