Composite laminated plate manufacturing mold

A technology of composite material layer and mould, which can be applied to household appliances, other household appliances, household components, etc., and can solve problems such as poor sealing, inability to obtain products, incomplete infiltration, etc., to facilitate disassembly and maintenance, and improve resin flow performance and improve the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

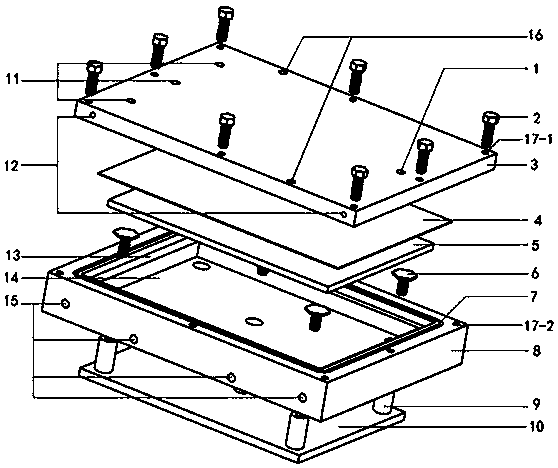

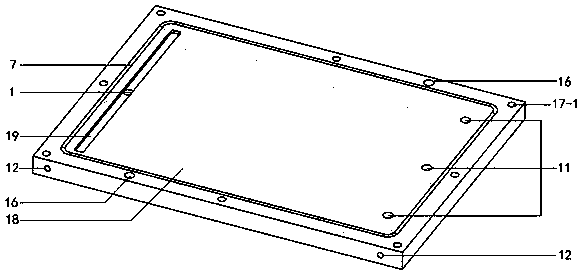

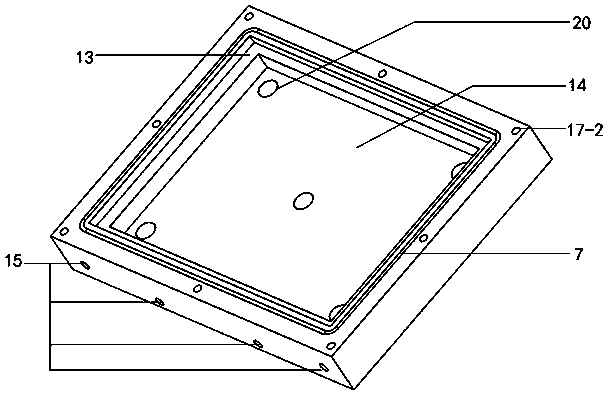

[0022] attached by figure 1 , 2 , 3, 4, 5, 7, and 8 show: a mold with continuously adjustable thickness, including fastening bolt 2, upper mold 3, lower template 4, upper top plate 5, ejector bolt 6, lower mold 8, top Rod 9 and lower top plate 10, a push rod 9 is respectively arranged at the middle position and four top corners of the lower top plate 10, and a push rod hole 20 corresponding to the push rod 9 is provided on the lower mold 8 and set The ejector rod fastening mechanism 21 on the ejector rod hole 20, the ejector rod 9 is set in the ejector rod hole 20 and can move freely in the ejector rod hole 20, and the ejector rod 9 is connected with the lower die by the ejector rod bolt 6 8 connection, the middle of the lower mold 8 is processed with a first stepped groove 13 and a second stepped groove 14, and the edge of the lower mold 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com