Method for preparing CZTS thin film solar cell using group IIIA element doped cadmium sulfide film

A technology of thin-film solar cells and group elements, which is used in circuits, electrical components, and final product manufacturing, etc., can solve problems such as the photoelectric conversion performance of devices, and achieve the effects of improving device efficiency, widening the width of depletion region, and improving photoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

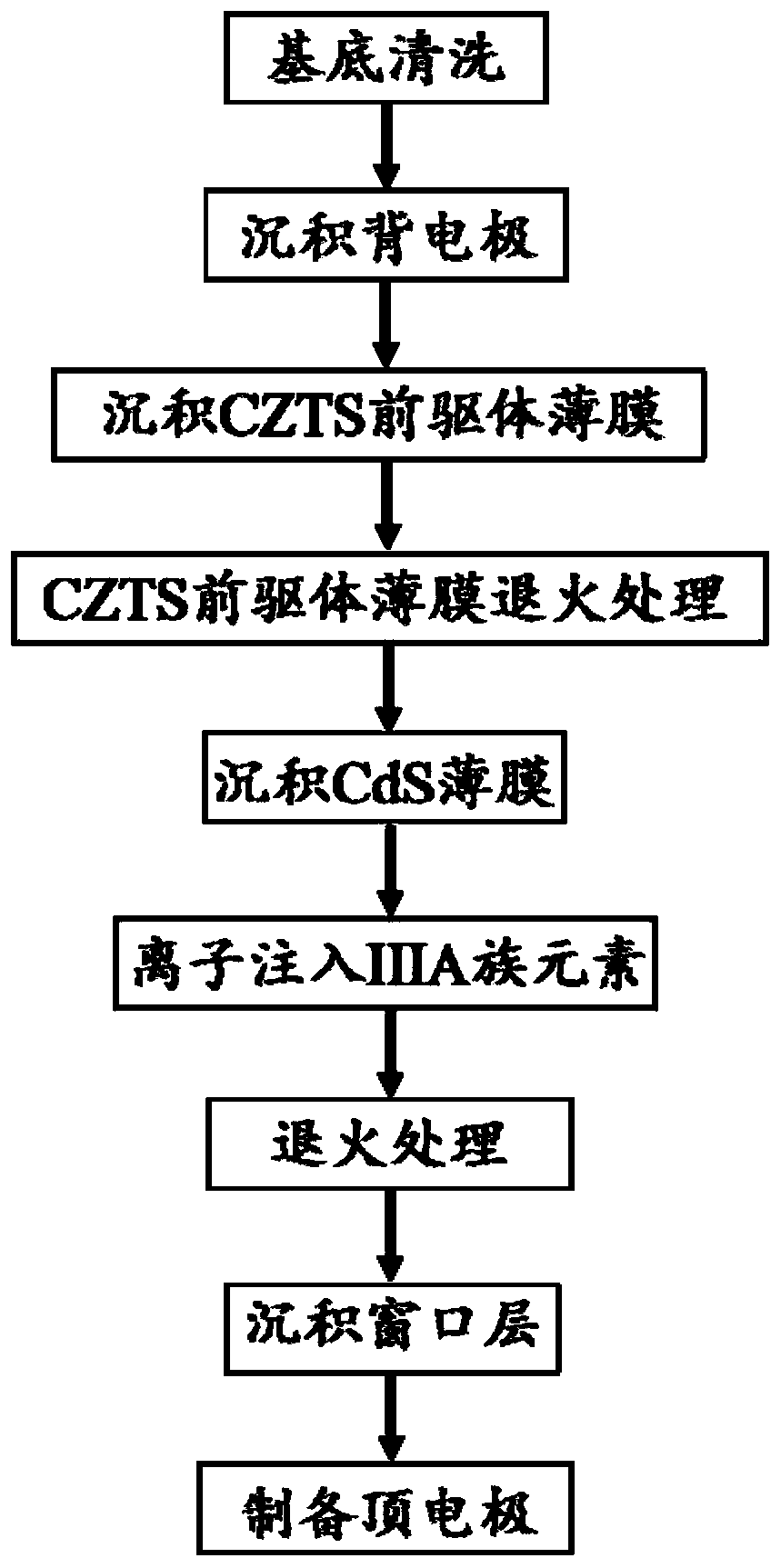

[0029] Please refer to figure 1 , according to the following steps to prepare CZTS thin film solar cells.

[0030] (1) Cut the soda-lime glass into a square of 3mm*3mm, ultrasonically clean it with deionized water, glass cleaner, acetone, alcohol, and deionized water for 15 minutes, and then dry it with a nitrogen gun.

[0031] (2) DC magnetron sputtering double-layer molybdenum was used as the back electrode on the cleaned soda-lime glass, and the thickness of the sputtered film was about 1 μm.

[0032] The sputtering power is 100W, and double-layer Mo is coated, that is, sputtering at 2Pa working pressure for 5 minutes to improve the bonding force with the glass substrate, and then sputtering at 0.3Pa working pressure for 15 minutes to obtain good electrical properties. The sheet resistance of the obtained Mo-coated glass is about 1.2Ω / □.

[0033] (3) The CZTS precursor film was deposited by sol-gel method.

[0034]Add copper acetate (1.6M), zinc acetate (1.0M), tin dic...

Embodiment 2

[0048] (1) Cut the FTO conductive glass into a square of 3mm*3mm, ultrasonically clean it with deionized water, glass cleaner, acetone, alcohol, and deionized water for 15 minutes, and then dry it with a nitrogen gun.

[0049] (2) Metal molybdenum was prepared as the back electrode on the cleaned soda-lime glass by thermal evaporation method.

[0050] Evaporation time 20min, vacuum degree 2×10 -5 Pa, evaporation current 90A, evaporation voltage 1.2V.

[0051] (3) The CZTS precursor film was prepared by continuous ion layer adsorption method, in which the ion layer was ZnS film and Cu 2 SnS 3 film.

[0052] Cu 2 SnS 3 Thin film deposition process: 0.005M CuSO 4 , 0.02M SnSO 4 and 0.01M NH 4 The mixed solution of F is the cation precursor solution, 0.01M Na 2 S is an anion precursor solution; ZnS film deposition process: 0.05M ZnSO 4 The solution is a cationic precursor solution, 0.01M Na 2 S is an anion precursor solution. The immersion and cleaning times during the...

Embodiment 3

[0066] (1) Cut the ITO conductive glass into a square of 3mm*3mm, ultrasonically clean it with deionized water, glass cleaner, acetone, alcohol, and deionized water for 15 minutes, and then dry it with a nitrogen gun.

[0067] (2) DC magnetron sputtering double-layer molybdenum was used as the back electrode on the cleaned soda-lime glass, and the thickness of the sputtered film was about 1 μm.

[0068] The sputtering power is 100W, and double-layer Mo is coated, that is, sputtering at 2Pa working pressure for 5 minutes to improve the bonding force with the glass substrate, and then sputtering at 0.3Pa working pressure for 15 minutes to obtain good electrical properties. The sheet resistance of the obtained Mo-coated glass is about 1.2Ω / □.

[0069] (3) The CZTS precursor film was deposited by sol-gel method.

[0070] Add copper acetate (1.6M), zinc acetate (1.0M), tin dichloride (0.8M) and thiourea (6.4M) to ethylene glycol methyl ether, the metal ratio is Cu / (Zn+Sn)= 0.84...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com